Method for renovating outer wall coated with fluorocarbon paint

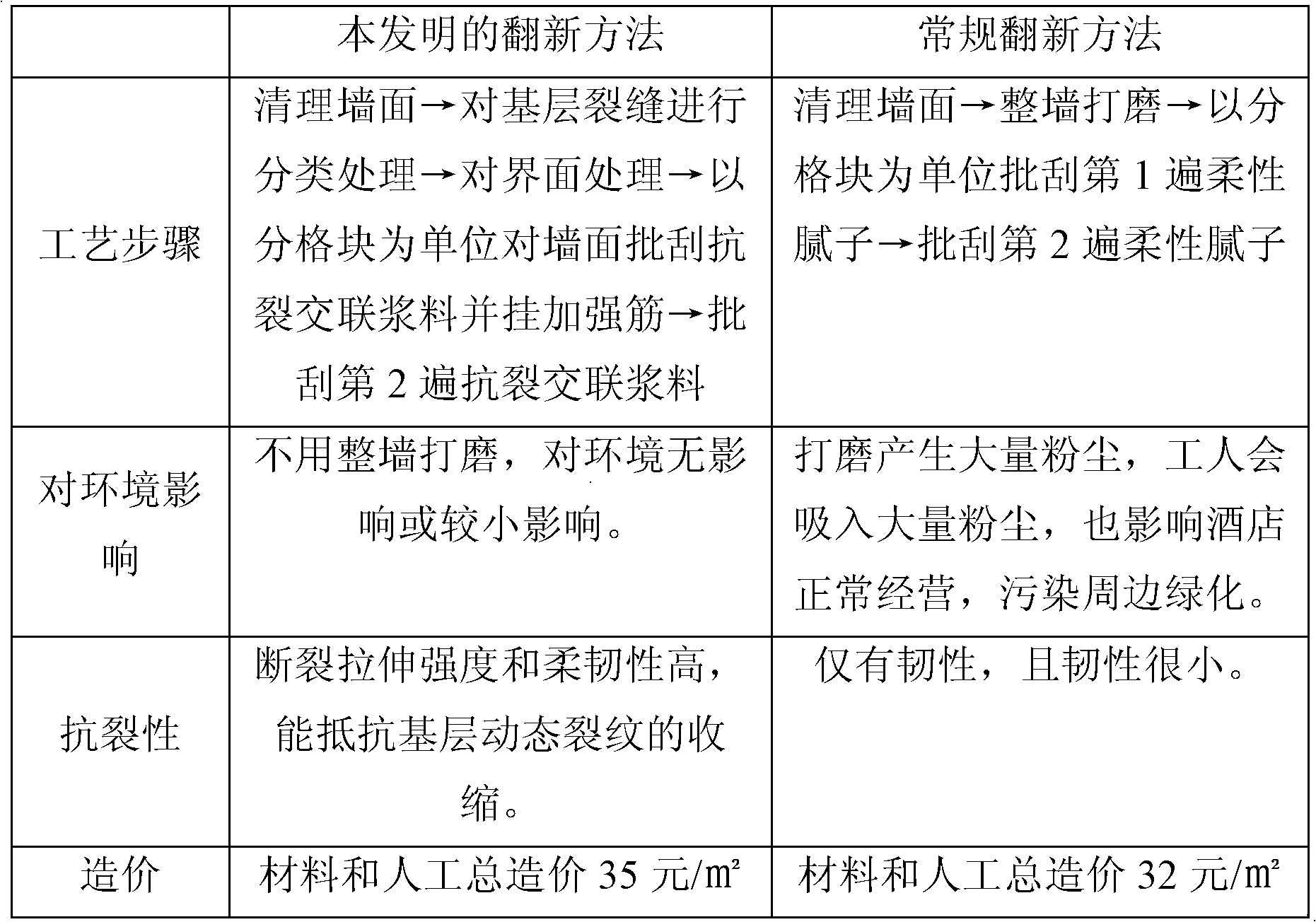

A fluorocarbon paint and exterior wall technology, applied in covering/lining, construction, building construction, etc., can solve the problems of easy re-cracking of the wall, poor adhesion of the old fluorocarbon paint interface, and good crack resistance of the wall, etc. Achieve good implementability, strong adhesion and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Apply fluorocarbon paint to the exterior wall of a high-rise hotel for renovation, including the following steps:

[0034] (1) Clean the wall surface: clean the efflorescence part with oxalic acid; remove the peeling, foaming and pulverized parts with a spatula first, then scrub with a wire brush, and clean the floating dust with a brush to make the surface of the base layer clean and sturdy.

[0035] (2) Classify the cracks in the base layer: for the tortoise cracks less than 1mm, use an electric grinder to grind along the cracks, the grinding depth is 2-3mm, and the grinding width is 100mm. For regular cracks and tortoise cracks larger than 1mm, first use Open a V-shaped groove with a width of 16 mm and a depth of 8 mm along the crack with an electric polisher, and clean up the floating ash, then brush a functional reinforcing interface agent on the V groove and both sides, and fill the V groove after the interface agent is dry. Putty TB-998, after the putty is dry, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com