Environment-friendly water-based crack paint and its application method

A water-based crack paint and crack finish paint technology, applied in the direction of coating, etc., can solve the problems of peeling off of the paint surface, non-cracking of the crack surface, and decline in quality, and achieve the effects of simple spraying and use, improved adhesion, and high safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

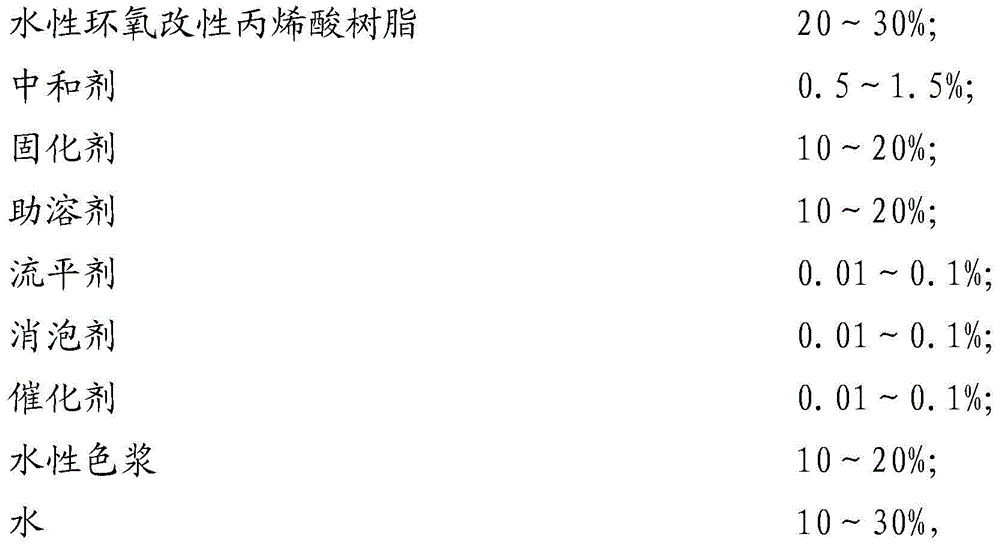

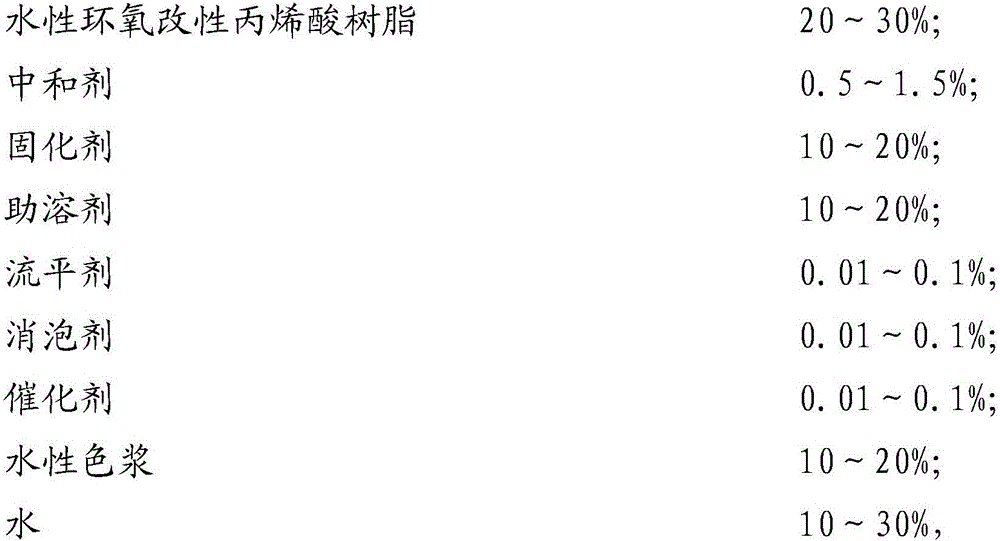

[0026] An environmentally friendly water-based crack paint, comprising a water-based crack primer and a water-based crack finish paint, the water-based crack primer includes: 20kg of water-based epoxy modified acrylic resin; 0.5kg of neutralizer; 20kg of curing agent; 20kg of cosolvent; leveling agent 0.01kg; defoamer 0.01kg; catalyst 0.01kg; water-based color paste 20kg; water 19.47kg, the water-based crack finish paint includes: styrene-acrylic emulsion 60kg; kg.

Embodiment 2

[0028] An environmentally friendly water-based crack paint, including water-based crack primer and water-based crack finish paint, the water-based crack primer includes: 22kg of water-based epoxy modified acrylic resin; 0.7kg of N,N-dimethylethanolamine; 18kg of amino resin; 18kg of alcohol; 0.03kg of leveling agent; 0.03kg of defoamer; 0.03kg of dibutyltin dilaurate; 18kg of water-based color paste; ; Water-based color paste 33.77kg; Water-based cracking agent 0.03kg.

Embodiment 3

[0030] An environmentally friendly water-based crack paint, comprising a water-based crack primer and a water-based crack finish paint, the water-based crack primer includes: 24kg of water-based epoxy-modified acrylic resin; 0.45kg of N,N-dimethylethanolamine, 0.45kg of diethanolamine; Blocked isocyanate 16kg; n-butanol 8kg, propylene glycol methyl ether 8kg; leveling agent 0.05kg; defoamer 0.05kg; dibutyltin dilaurate 0.02kg, dodecylbenzenesulfonic acid 0.03kg; 26.95kg of water, the water-based crack finish paint includes: 70kg of styrene-acrylic emulsion; 1.4kg of neutralizer; 28.55kg of water-based color paste; 0.05kg of water-based crack agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com