Method of preventing sulfide corrosion, high-temperature member with resistance to sulfide corrosion, and method of repairing heat-transfer tube

An anti-vulcanization and heat-conducting tube technology, applied in chemical instruments and methods, liquid chemical plating, solid-state chemical plating, etc., can solve the problems of high coating cost and coating peeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

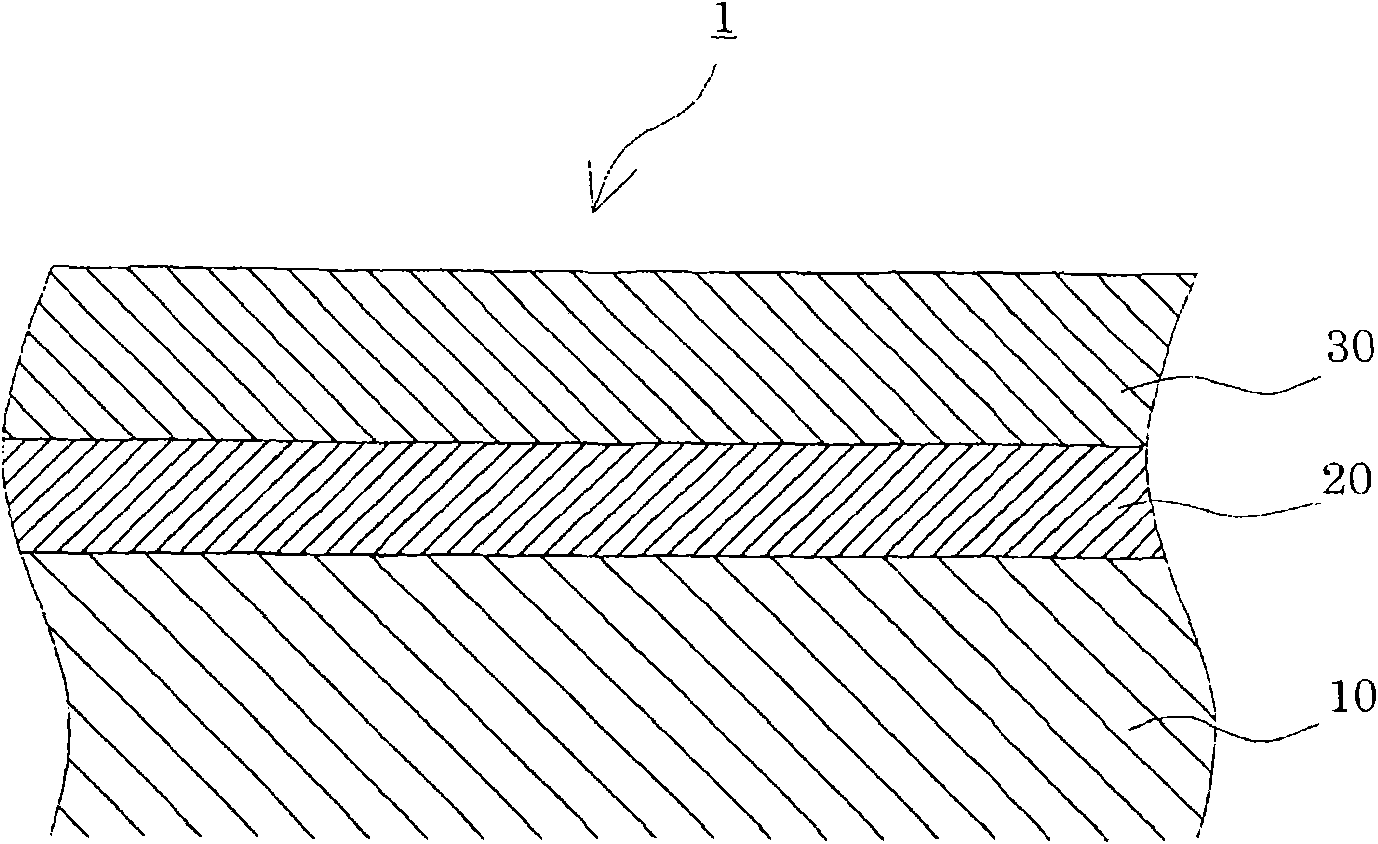

figure 1 It is a schematic diagram showing a sulfide corrosion-resistant high-temperature component according to the present embodiment. Such as figure 1 As shown, the sulfide corrosion-resistant high-temperature component 1 is a component in which a silicon oxide layer 20 and a first titanium oxide layer 30 are sequentially formed on the surface of a base material 10 .

[0053] The silicon oxide layer 20 is not particularly limited as long as it can be densely formed on the surface of the substrate 10 , and is preferably in an amorphous state. By making the silicon oxide layer 20 in an amorphous state, which will be described in detail later, it is possible to prevent cracks from occurring in the first titanium oxide layer 30 when forming the first titanium oxide layer 30, and to form a dense layer with very few cracks. uniform first titanium oxide layer 30.

[0054] As the silicon oxide constituting the silicon oxide layer 20, for example, SiO, SiO 2 or a mixture of them....

Embodiment approach 2

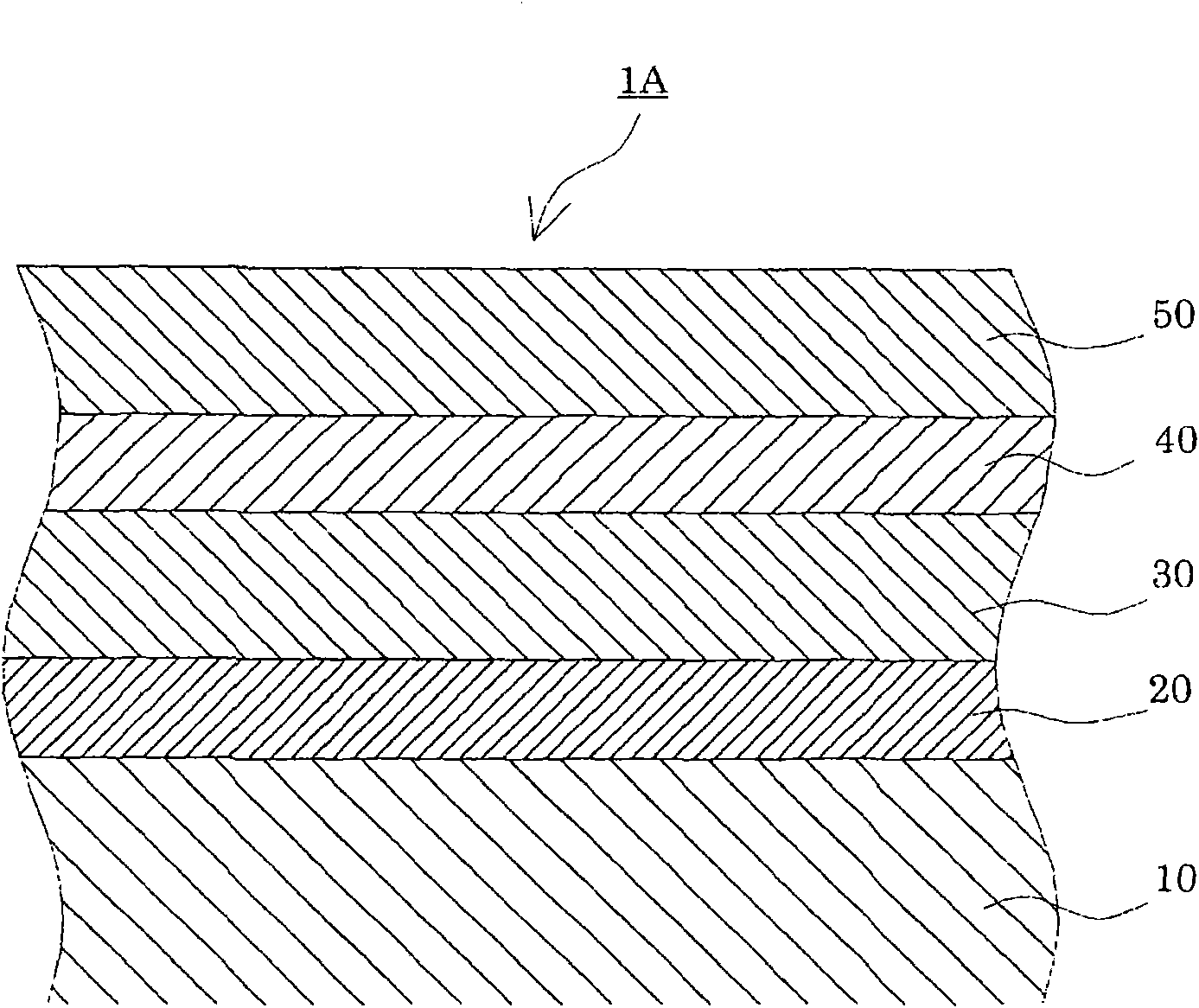

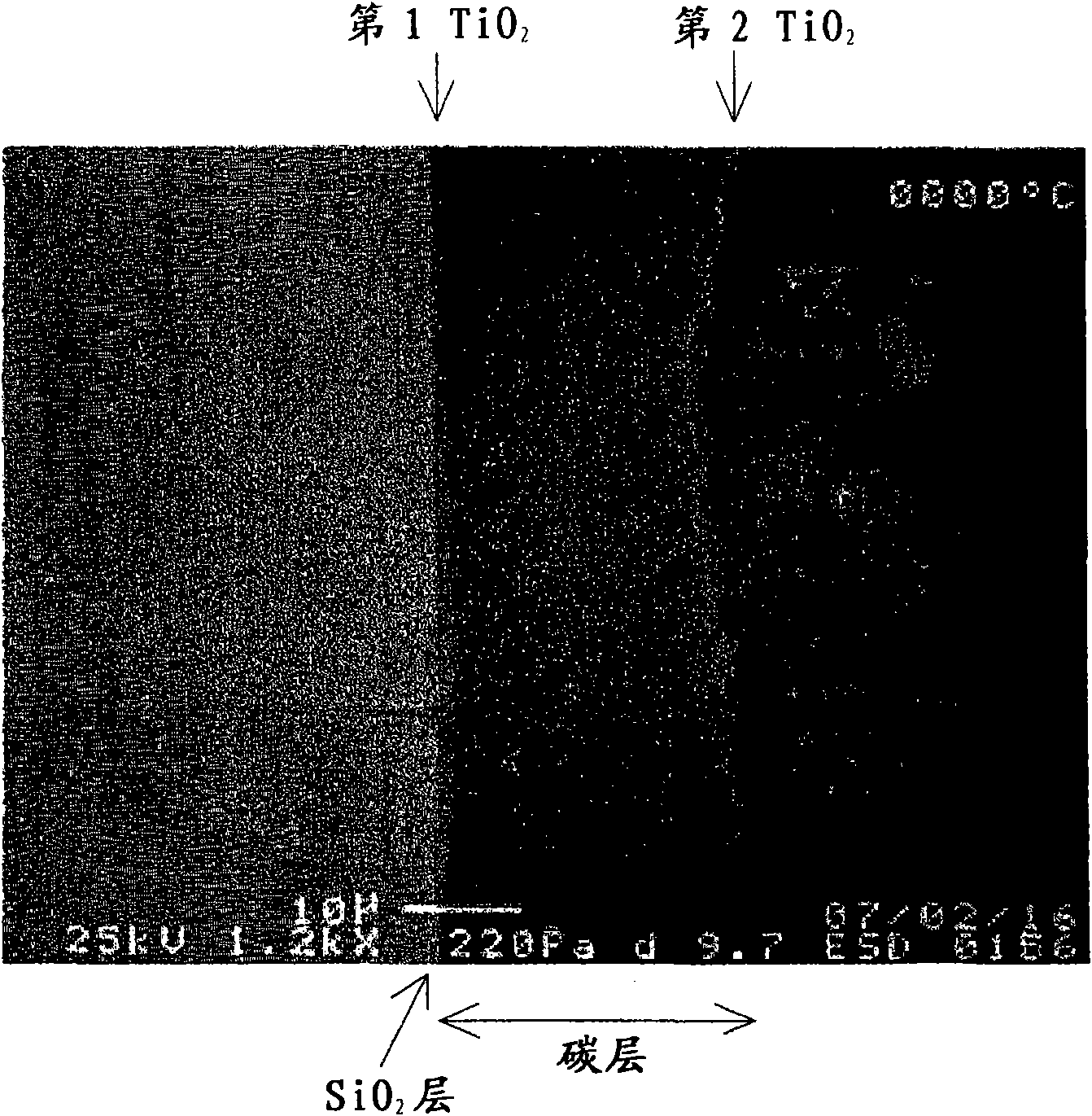

figure 2 It is a schematic diagram showing the sulfide corrosion-resistant high-temperature component of the present embodiment. The sulfidation corrosion resistant high temperature component 1A of the present embodiment is as figure 2 As shown, a carbon layer 40 and a second titanium oxide layer 50 are further provided on the first titanium oxide layer 30 . That is, the sulfide corrosion-resistant high-temperature component 1A of the present embodiment is composed of a silicon oxide layer 20, a first titanium oxide layer 30, a carbon layer 40, and a second titanium oxide layer 50 sequentially provided on the surface of a base material 10. A 5-layer structure is formed.

[0070] The carbon layer 40 is not particularly limited as long as it can be provided on the first titanium oxide layer 30 . In addition, the thickness of the carbon layer 40 is not particularly limited, but is preferably in the range of 10 to 30 μm. The carbon layer 40 having a thickness in this range ca...

Embodiment approach 3

In Embodiments 1 and 2, the silicon-containing coating liquid and the titanium-containing coating liquid were applied separately and thermally oxidized, but the present invention is not limited thereto, and thermal oxidation may be performed collectively.

[0078] For example, a silicon-containing coating liquid is coated on the substrate 10 and dried to form a silicon-containing coating layer (first coating step).

[0079] Next, a titanium-containing coating liquid is applied on the silicon-containing coating layer, and dried to form a first titanium-containing coating layer (second coating step).

[0080] Next, a carbon layer 40 is formed on the first titanium-containing coating layer (carbon layer forming step).

[0081] Next, a titanium-containing coating liquid is applied on the carbon layer 40 and dried to form a second titanium-containing coating layer (third coating step).

[0082] Finally, the silicon-containing coating layer, the first and second titanium-containing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com