Walnut shell breaking device

A shell breaking device and walnut technology, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of slow speed and low rate of exposed kernels, and achieve fast breaking speed, ensure the rate of exposed kernels, and improve production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

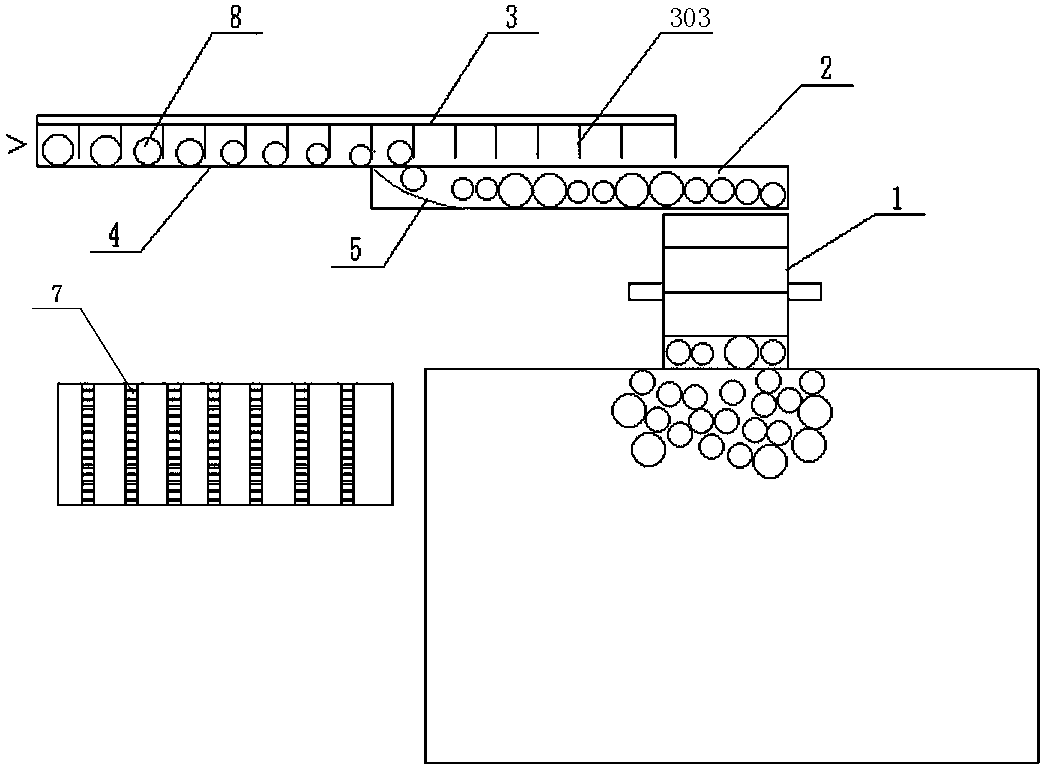

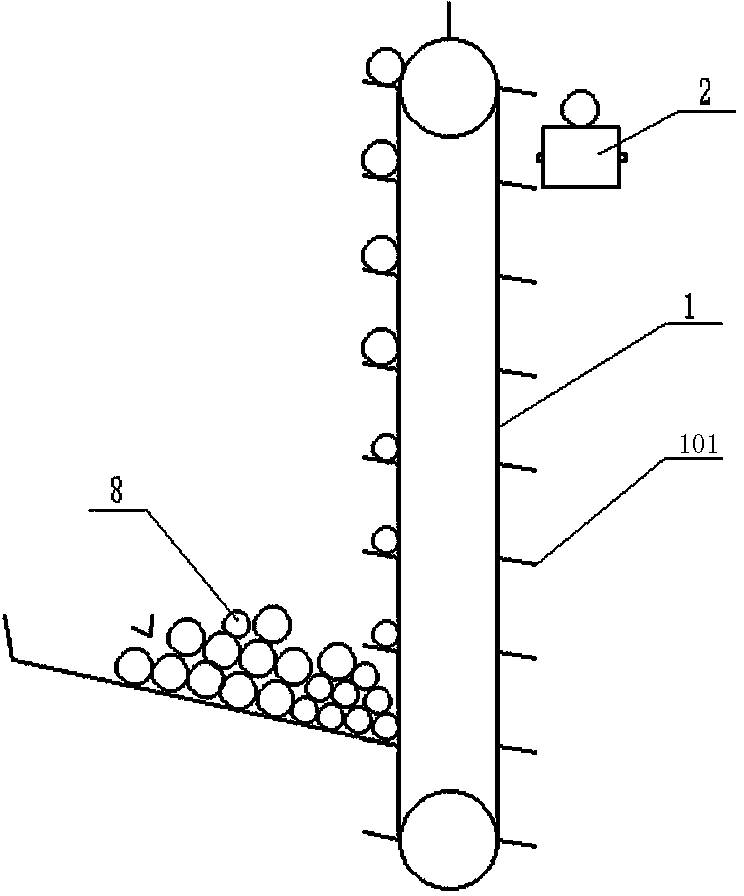

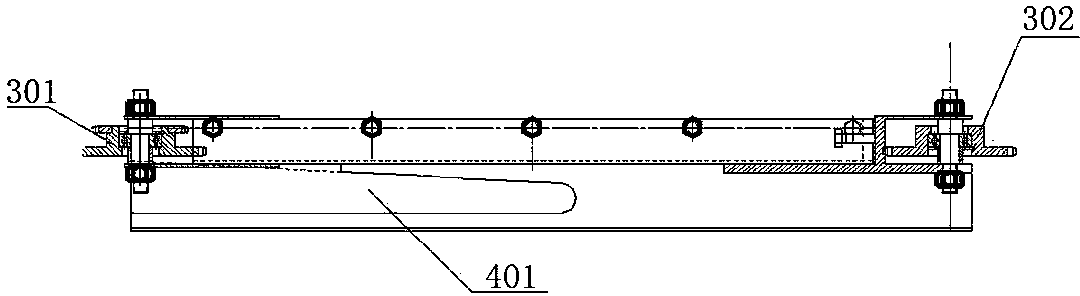

[0010] Such as figure 1 The shown walnut shell breaking device includes a vertical hoist 1, a horizontal conveyor belt 2, a plate feeder 3, an inclined leaking trough 4, a shell breaking mechanism and a frame; the vertical hoist 1 is vertically Arranged on the top, it includes rollers fixed on the upper and lower ends of the frame, on which a belt is installed, and lifting plates 101 at an angle to the belt are fixed at intervals on the surface of the belt. The drum is driven by the motor to drive the belt to move. The lower end of the belt is placed in the hopper for storing walnuts. When the belt moves upwards, each lifting plate 101 lifts a certain amount of walnuts from the hopper to group the walnuts.

[0011] Such as figure 1 , figure 2 As shown, the horizontal conveyor belt 2 is arranged in the horizontal direction, and the rear end of the horizontal conveyor belt 2 overlaps with the top of the vertical hoist 1, and the grouped walnuts are vertically lifted onto the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com