Dry powder crackle coating and construction method

A technology of crack paint and construction method, which is applied in the field of interior wall paint and its construction, can solve the problems of insufficient environmental protection of organic solvents and complicated construction methods, and achieve the effects of good three-dimensional effect, simple preparation process and construction process, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

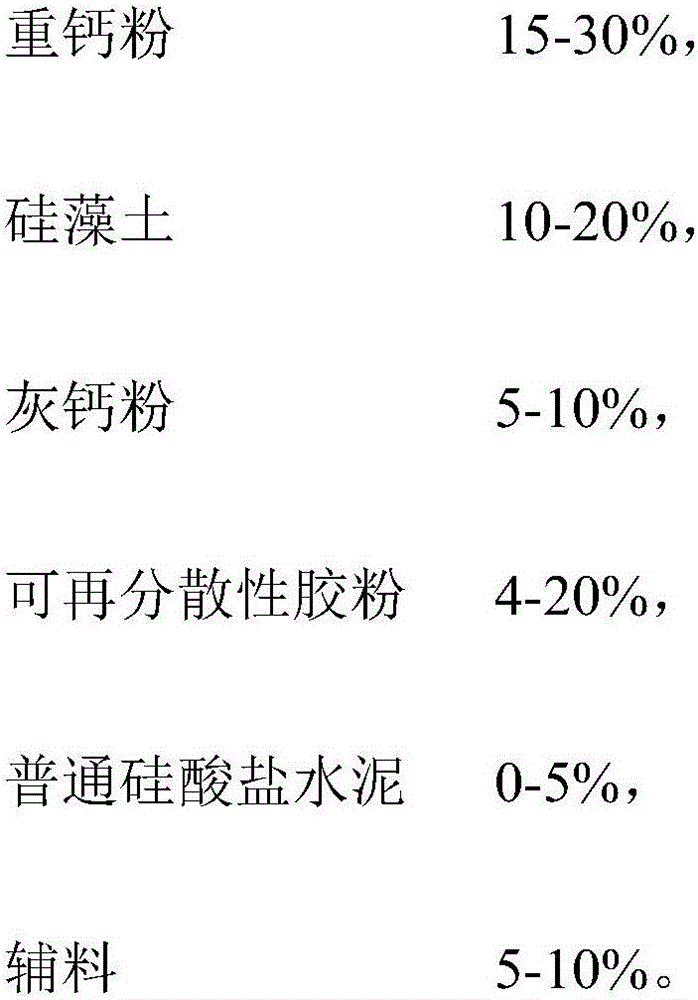

[0016] The embodiment of the present invention provides a kind of dry powder crack coating, is made up of the composition of following percentage by weight:

[0017]

[0018] In Example 1, the auxiliary material is a mixture of bentonite and cellulose ether, 2% of bentonite and 3% of cellulose ether in the 5% auxiliary material.

[0019] The bentonite is used as a thixotropic lubricant, and the cellulose ether is used as a thickener.

Embodiment 2

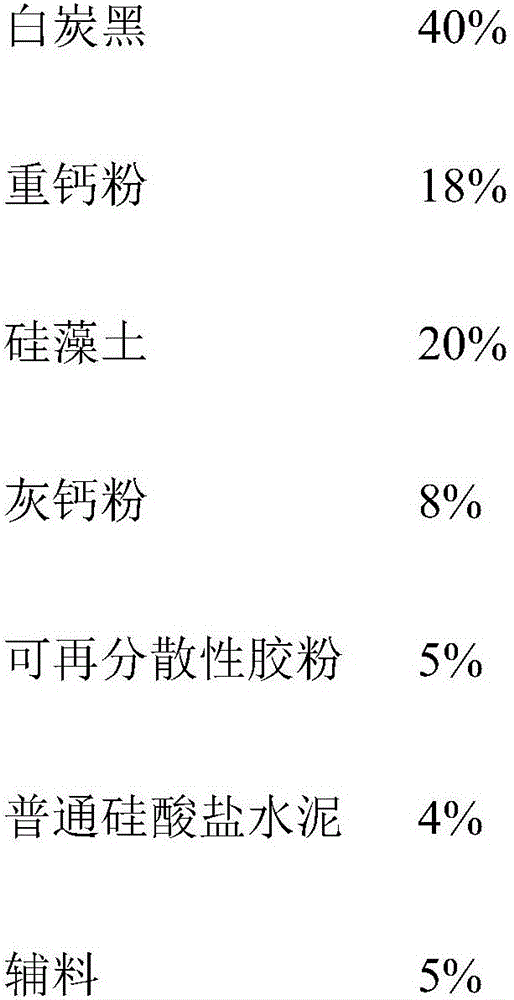

[0021] The embodiment of the present invention provides a kind of dry powder crack coating, is made up of the composition of following percentage by weight:

[0022]

[0023] In Example 2, the auxiliary material is a mixture of bentonite and starch ether, 2% of bentonite and 3% of starch ether in 5% of the auxiliary material.

[0024] The bentonite is used as a thixotropic lubricant, and the starch ether is used as a thickener.

Embodiment 3

[0026] The embodiment of the present invention provides a kind of dry powder crack coating, is made up of the composition of following percentage by weight:

[0027]

[0028]

[0029] In Example 3, the auxiliary material is a mixture of starch ether and cellulose ether, 4% of starch ether and 6% of cellulose ether in 10% of the auxiliary material.

[0030] The starch ether and cellulose ether are used as thickeners.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com