Resistance-type flexible carbon fiber strain sensor and manufacturing method thereof

A technology of a strain sensor and a manufacturing method, applied in the field of flexible sensors, can solve the problems of poor controllability and anti-interference ability, difficult to adjust the working range and sensitivity, etc., and achieve the effects of high sensitivity, reduced manufacturing difficulty and strong controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

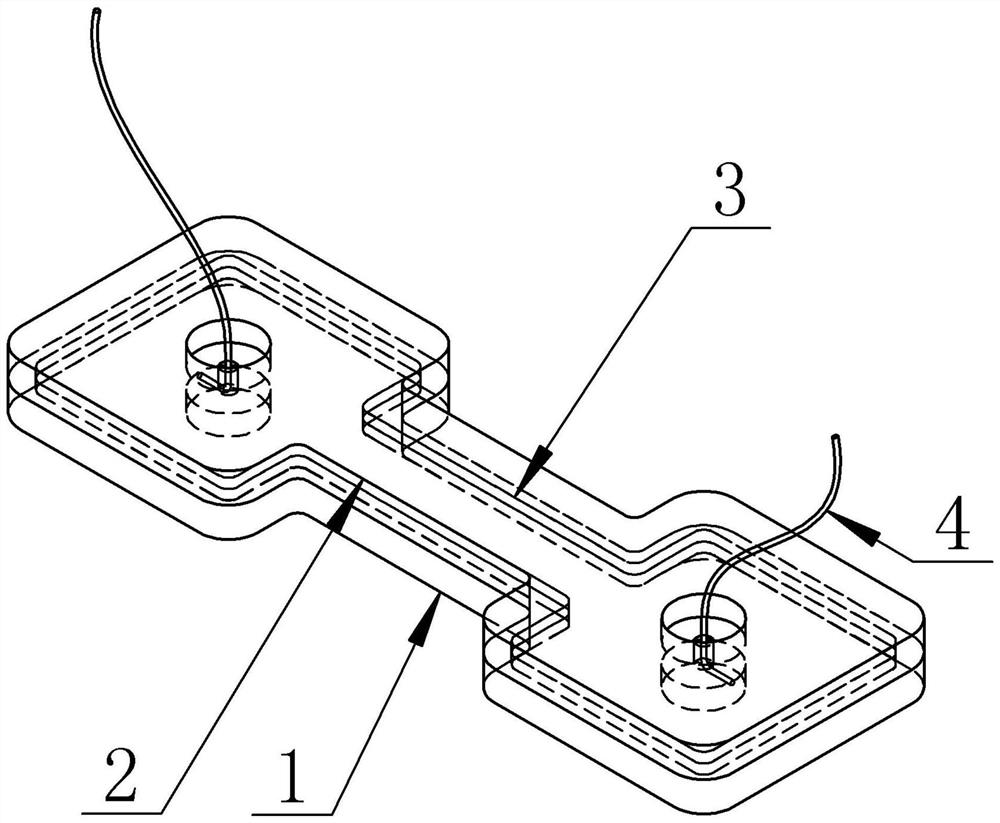

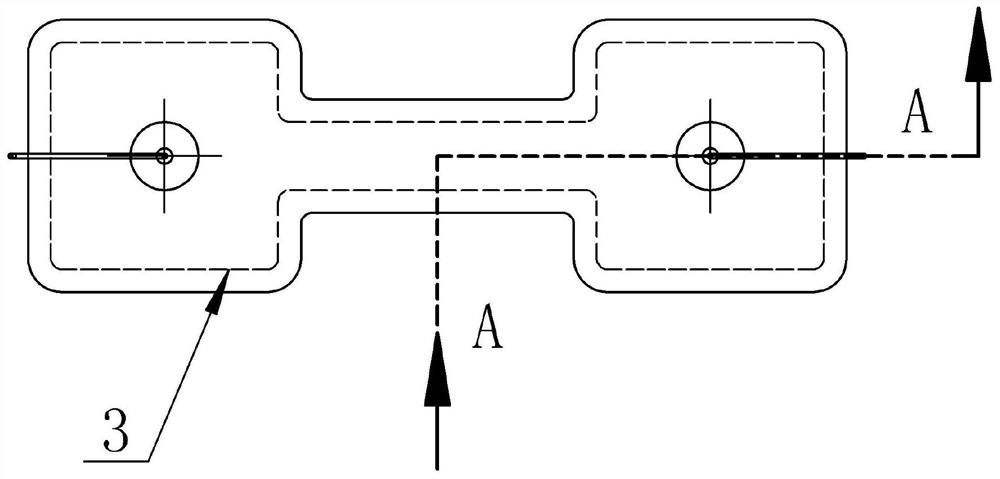

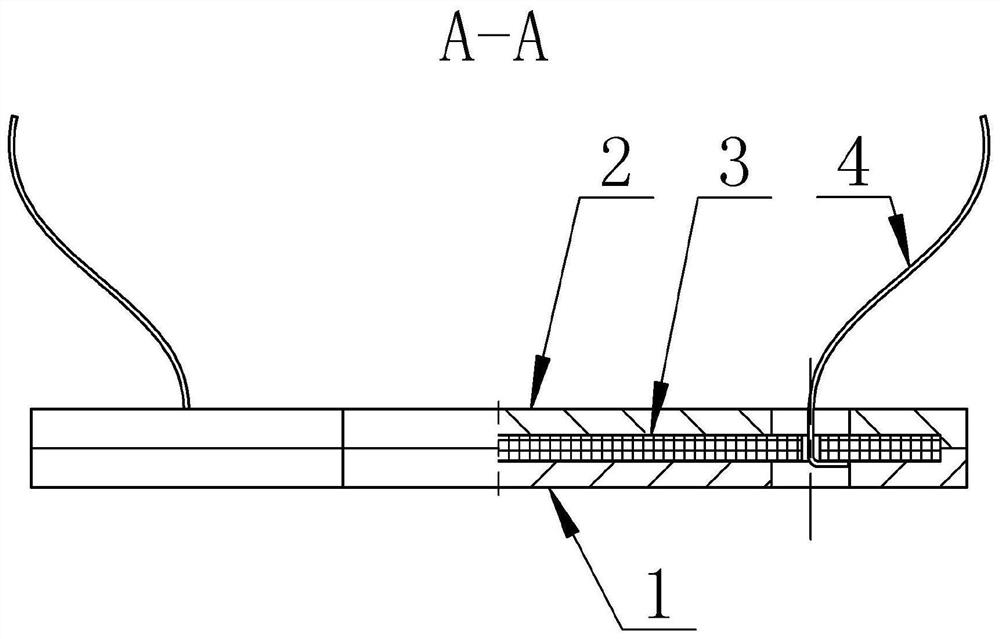

[0039] like Figure 1-3 As shown, this embodiment provides a resistive flexible carbon fiber strain sensor, which includes an upper protective layer 1, a sensitive element 3, a lower protective layer 2, and a wire 4 that are sequentially stacked from top to bottom; wherein, the wires 4 are respectively connected to The left and right ends of the sensitive element 3; wherein, the material for making the sensitive element 3 includes carbon fiber prepreg.

[0040] Specifically, the carbon fiber prepreg is composed of epoxy resin and carbon fiber filaments arranged in parallel in one direction. The carbon fiber filaments arranged in parallel are easy to form micron-scale cracks under stress, and the carbon fiber filaments have good electrical conductivity. This makes the resistive flexible carbon fiber strain sensor provided by the invention have extremely high sensitivity. At the same time, carbon fiber prepreg is a standard commercial material, and its processing technology is ...

Embodiment 2

[0047] This embodiment provides a manufacturing method of the resistive flexible carbon fiber strain sensor of Embodiment 1, such as Figure 7 As shown, the method specifically includes:

[0048] S1: Laminating the multi-layer carbon fiber prepreg to obtain a laminated part;

[0049] Specifically, since the carbon fiber prepreg contains epoxy resin, the epoxy resin is no longer viscous after being heated and cured. Therefore, during the pressing step, it is necessary to simultaneously press the multi-layer carbon fiber prepreg. For example, two layers of carbon fiber prepreg with a thickness of 0.02 mm are pressed together with a fixture, wherein the carbon fiber filaments of the lower carbon fiber prepreg are placed vertically, and the carbon fiber filaments of the upper carbon fiber prepreg are vertical to the lower layer. The placed carbon fiber filaments are placed obliquely at an included angle α.

[0050] S2: heating and curing the pressed part to obtain a first cured ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com