Low gas permeability coal seam liquid phase co 2 Phase change fracturing anti-reflection mesh gas drainage method

A technology of gas drainage and coal seam gas, applied in the direction of gas discharge, mining equipment, mining fluid, etc., to achieve the effect of increasing the amount of gas drainage, low input cost, and preventing coal and gas outburst accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

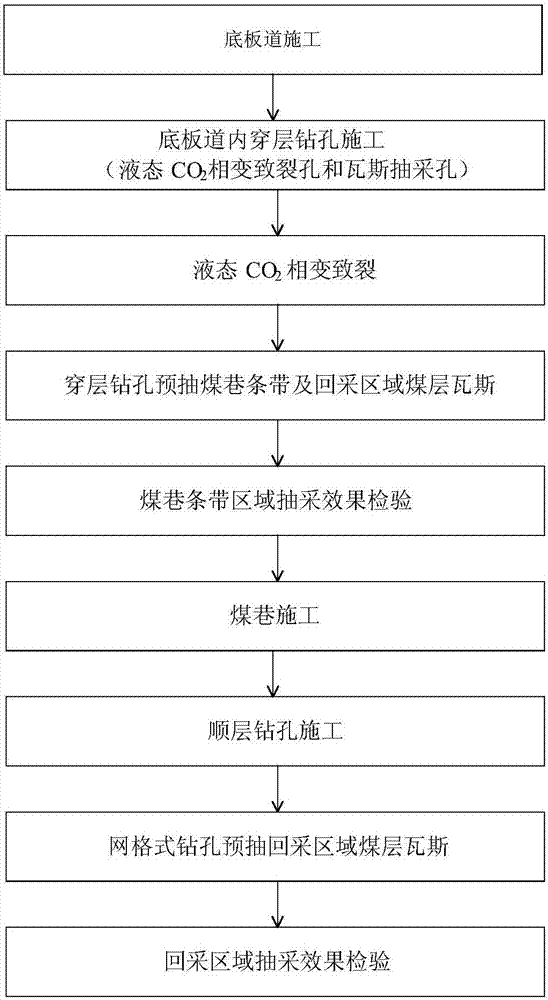

[0061] Such as figure 1 As shown, a low gas permeability coal seam liquid CO 2 The phase change fracturing anti-reflection grid gas drainage method includes the following steps:

[0062] 1) Construction floor road

[0063] According to the geological conditions of the coal seam floor, within the range of 10m to 30m below the coal seam, choose a rock layer with weak rock quality and low rock strength, which is easy to carry out floor road construction. A floor road is constructed by drilling and blasting excavation or other excavation methods, and the section of the roadway is 4m× 3m, using rectangular W steel belt anchor net support;

[0064] 2) Drilling construction of the inner layer of the floor road

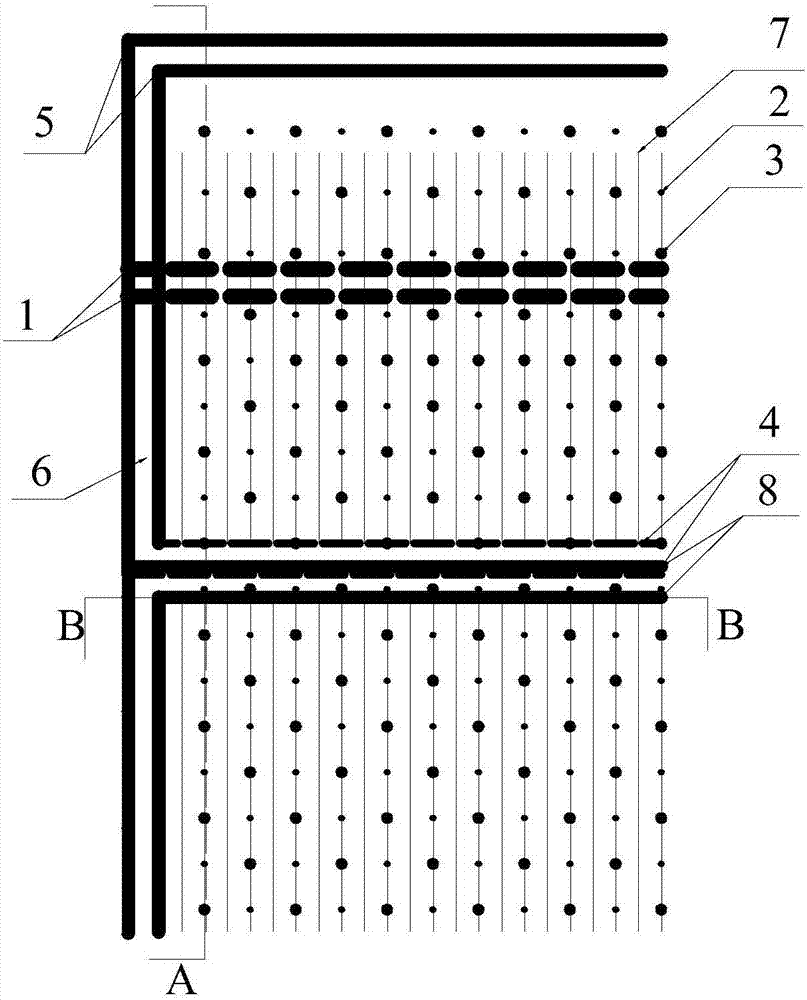

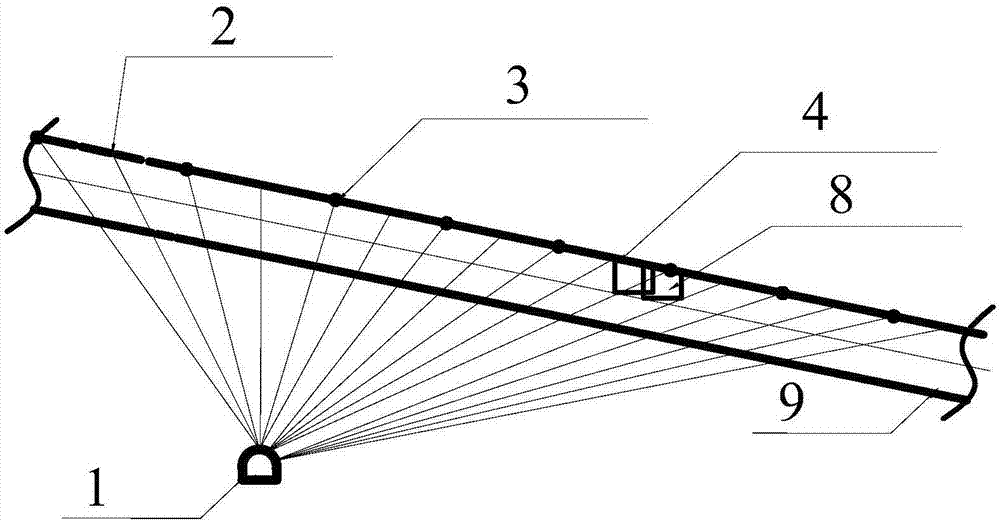

[0065] Such as figure 2 and image 3 As shown in Fig. 1, a group of floor-through-layer drilling holes are constructed in floor-way 1 at intervals of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com