Method and device for dredging pores and cracks of coal seam gas extraction drill hole

A technology for drilling and coal seam gas drainage, which is applied in the direction of wellbore/well valve devices, mining fluids, earthwork drilling, etc. It can solve the problems of affecting the drilling drainage volume and increasing the gas drainage volume, and achieves an increase Gas drainage volume and the effect of improving drainage efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

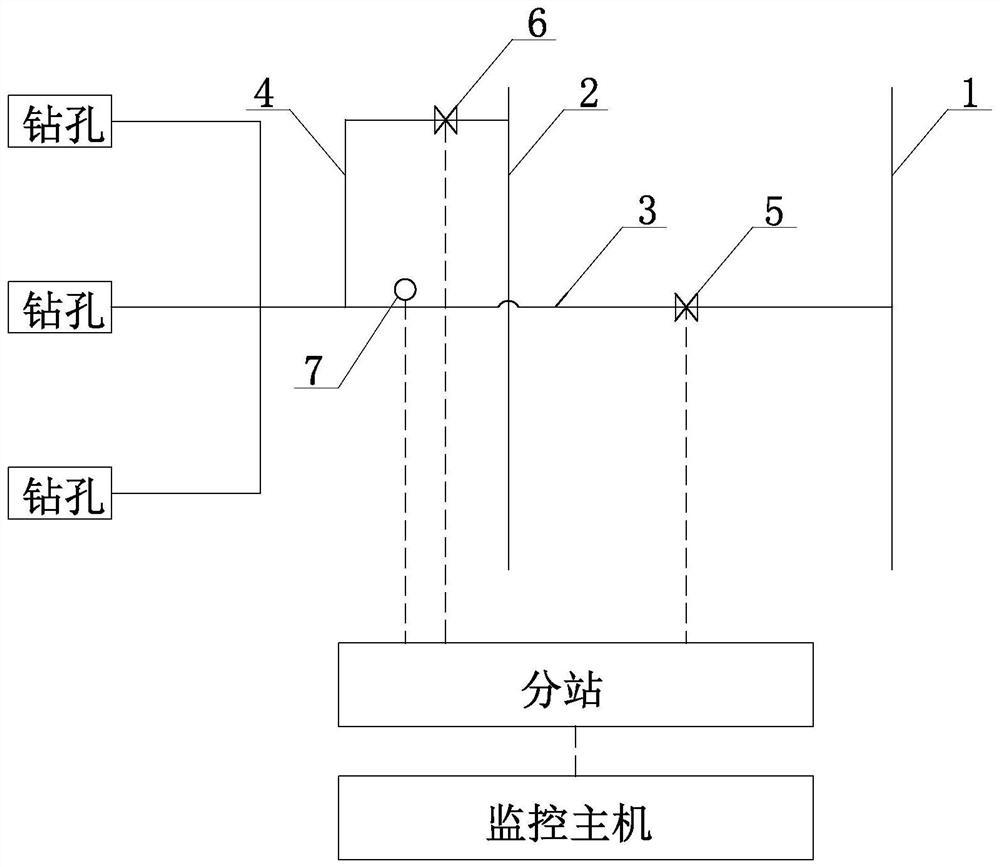

[0033] Such as figure 1 As shown, a device for dredging coal seam gas drainage borehole pores and fissures includes a negative pressure pipe 1 and a positive pressure pipe 2 communicating with the borehole, and the negative pressure pipe 1 is connected to the drill hole through a first connecting pipe 3 hole, the first connecting pipe 3 is equipped with a metering unit 7 and a first valve 5, the metering unit 7 is used to detect gas flow and pressure, the positive pressure pipe 2 is connected to the drill through the second connecting pipe 4 A second valve 6 is installed on the second connecting pipe 4, and the boreholes communicate with each other.

[0034] Wherein, the first valve 5 and the second valve 6 are mine electric valves, the metering unit 7, the first valve 5 and the second valve 6 are connected to a substation, and the substation is connected to a monitoring host.

[0035] Wherein, the metering unit 7 adopts a combined sensor GD3.

[0036] A device for dredging ...

Embodiment 2

[0042] Such as figure 1 As shown, a method for dredging coal seam gas drainage borehole pores and fissures comprises the following steps:

[0043] Step S1, installation: connect the borehole to the negative pressure pipe 1 and the positive pressure pipe 2, install a metering unit 7 and a first valve 5 between the borehole and the negative pressure pipe 1, and install the metering unit 7 and the first valve 5 between the borehole and the positive pressure pipe 2. A second valve 6 is installed between the pressure pipes 2;

[0044] Step S2, initialization: closing the second valve 6, opening the metering unit 7 and the first valve 5;

[0045]Step S3, negative pressure dredging: when the metering unit 7 detects that the gas flow rate Q≤the first set value, the first valve 5 is closed, and the blockages in the pores and fissures of the coal seam gas drainage drilling are under positive pressure Dredging is carried out under the action of the metering unit 7 until the pressure P ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com