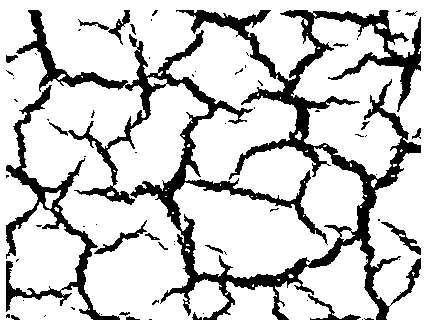

Crack paint and preparation method thereof

A technology of cracked paint and mother liquor, applied in the direction of coating, etc., can solve the problems of destroying the three-dimensional artistic beauty of cracked paint, uneven crack size, and destroying decorative effects, etc., and achieve the effect of uniform cracks, beautiful patterns, and easy construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

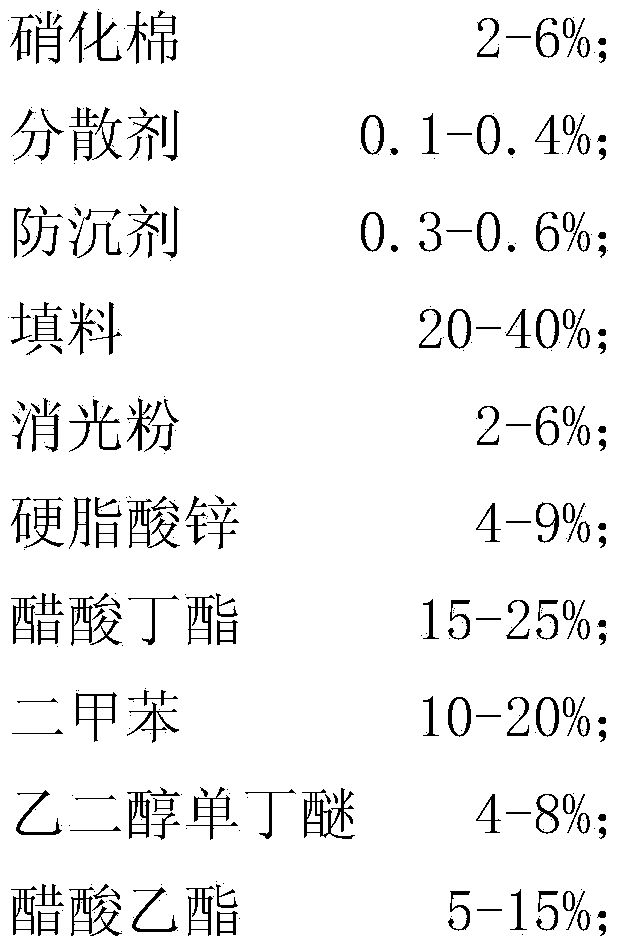

[0049] Put 3Kg of 1 / 2 second nitrocellulose into the dispersing cylinder filled with 7Kg of butyl acetate and mix for 3-5min under the low-speed stirring of the mixer. After the nitrocellulose is dissolved, add 0.2Kg of dispersant and 0.4Kg of anti-sedimentation agent Quickly disperse for 3-5min, add 15Kg butyl acetate, 5Kg xylene, 6Kg ethylene glycol monobutyl ether and stir evenly, add 28Kg calcium carbonate and 8Kg zinc stearate for high-speed dispersion for 10-15min, then add 12.4Kg xylene and stir evenly , then add 4Kg matting powder to disperse at high speed for 5-10min, finally add 11Kg ethyl acetate and stir for 3-5min, after stirring well, the crack paint mother liquor is obtained.

[0050] When in use, 80Kg crack paint mother liquor and 20Kg titanium white slurry are stirred at high speed for 15-20 minutes, and the finished crack paint that is easy to construct and has beautiful cracks can be obtained. During construction, mix and dilute the easy-to-construction and ...

Embodiment 2

[0053] Put 4Kg of 1 / 2 second nitrocellulose into the dispersing cylinder filled with 7.2Kg of butyl acetate and mix for 3-5min under the low-speed stirring of the mixer. After the nitrocellulose is dissolved, add 0.3Kg of dispersant and 0.5Kg of anti-sedimentation agent Disperse at medium speed for 3-5 minutes, add 15Kg butyl acetate, 6Kg xylene, 7Kg ethylene glycol monobutyl ether and stir evenly, add 35Kg calcium carbonate and 5Kg zinc stearate and disperse at high speed for 10-15min, then add 10Kg xylene and stir evenly , then add 3Kg matting powder to disperse at high speed for 5-10min, finally add 7Kg ethyl acetate and stir for 3-5min, stir well and pack to obtain crack paint mother liquor.

[0054] When in use, stir 85Kg of the crack paint mother liquor and 15Kg of the red paste at high speed for 15-20 minutes to obtain a finished crack paint that is easy to construct and has beautiful cracks. During construction, mix and dilute the easy-to-construction and beautiful cra...

Embodiment 3

[0057] Put 4Kg of 1 / 2 second nitrocellulose into the dispersing tank filled with 8Kg of butyl acetate and mix for 3-5min under the low-speed stirring of the mixer. After the nitrocellulose is dissolved, add 0.3Kg of dispersant and 0.5Kg of anti-sedimentation agent Quickly disperse for 3-5min, add 15Kg butyl acetate, 6Kg xylene, 5Kg ethylene glycol monobutyl ether and stir evenly, add 33Kg calcium carbonate and 7Kg zinc stearate for high-speed dispersion for 1-15min, then add 10Kg xylene and stir evenly, Then add 3.2Kg of matting powder and disperse at high speed for 5-10 minutes, finally add 8Kg of ethyl acetate and stir for 3-5 minutes, stir well and pack to obtain crack paint mother liquor.

[0058]When in use, mix 82Kg of crack paint mother liquor and 18Kg of fluorescent lemon yellow slurry at high speed for 15-20 minutes to obtain a finished crack paint that is easy to construct and has beautiful cracks. During construction, mix and dilute the easy-to-construction and beau...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com