High-purity quartz sand preparation process

A technology of high-purity quartz sand and preparation process, applied in the field of high-purity quartz sand preparation technology, can solve the problems of pollution, damage, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

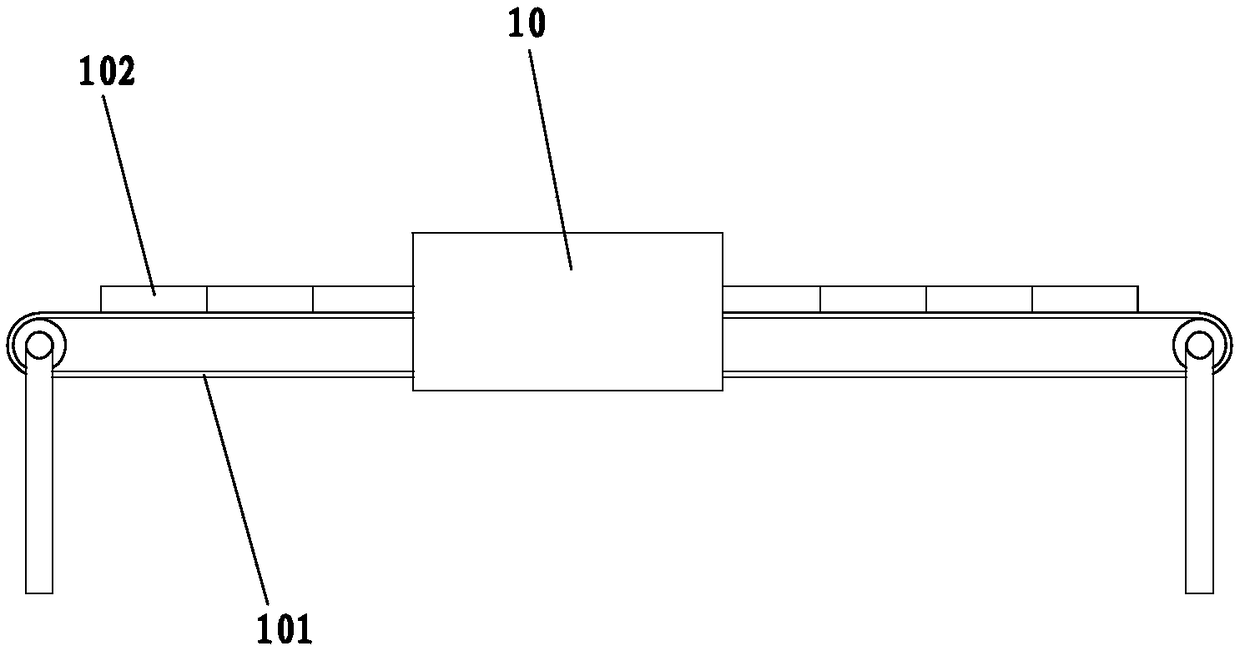

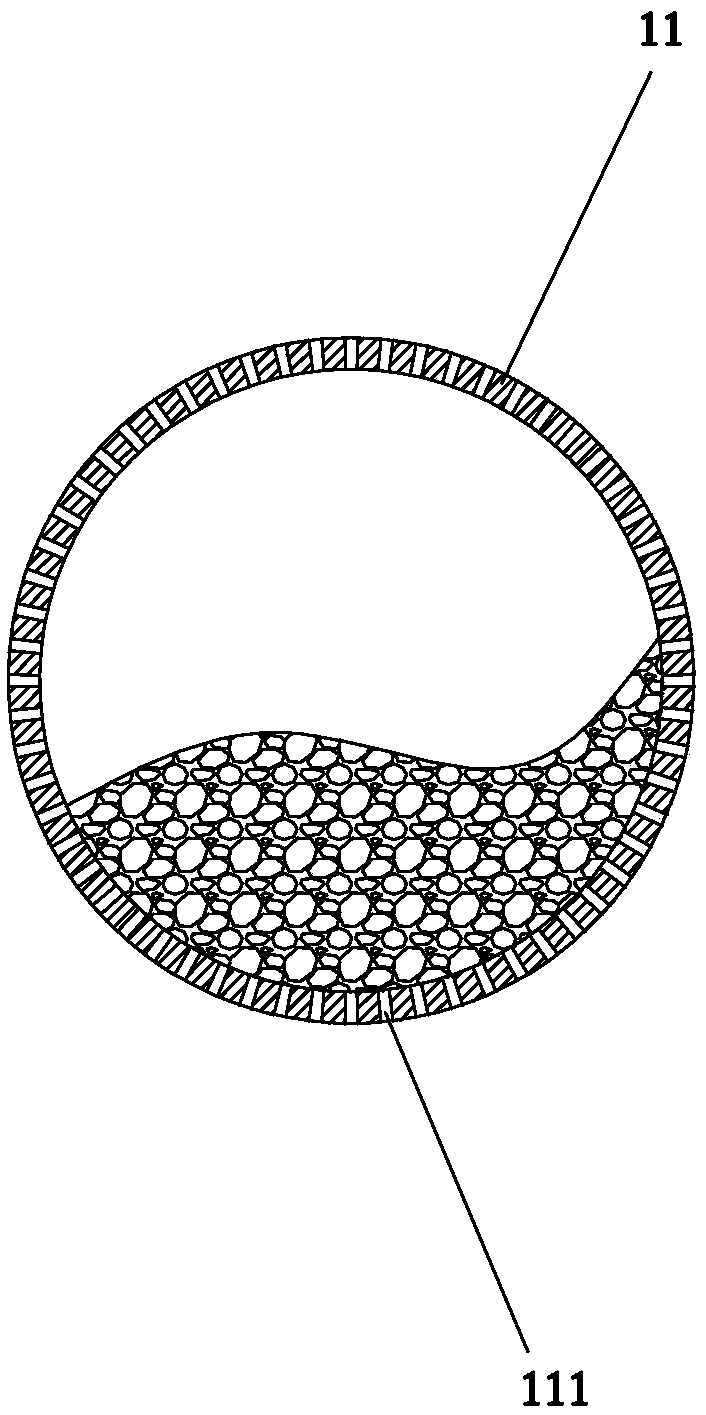

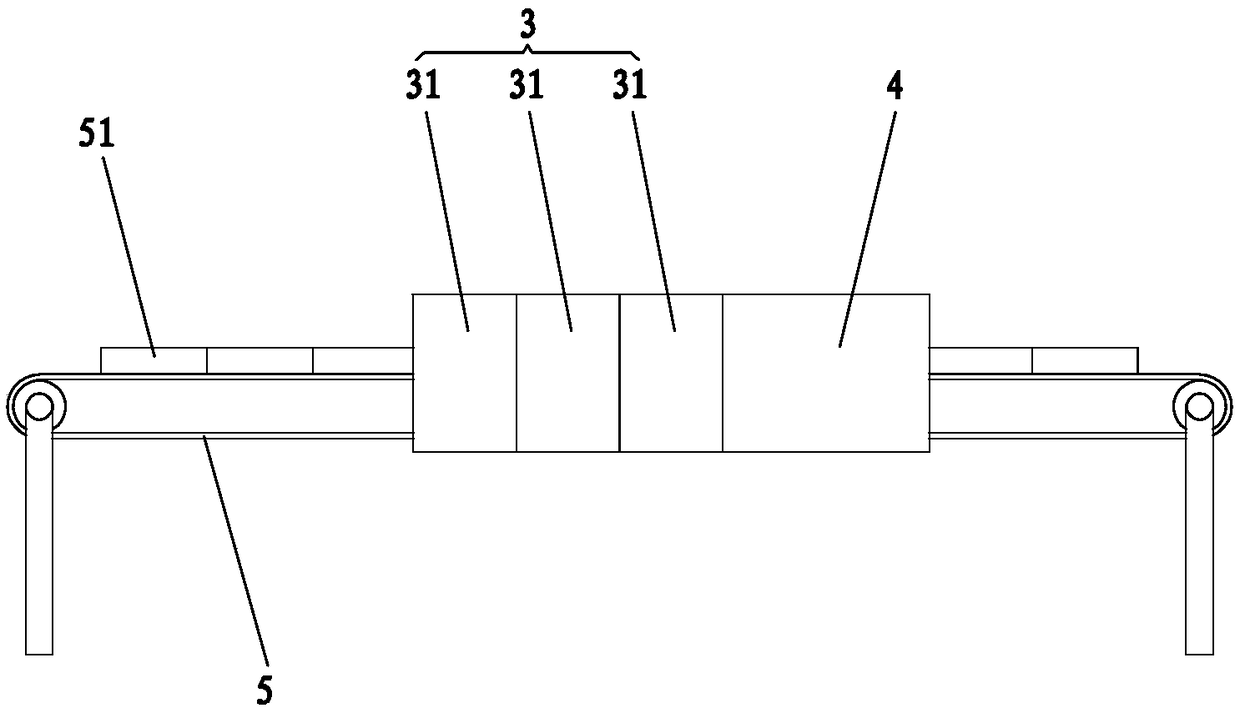

[0042] A kind of high-purity quartz sand preparation technology of the present invention, as Figure 1-4 shown, including the following steps:

[0043] (1) Carry out manual mineral processing according to the quality of quartz ore raw materials;

[0044] (2) Rinse the quartz ore raw material with running water. Specifically, the quartz ore raw material can be impacted and cleaned by water jets, and the removal strength is stronger and more thorough;

[0045] (3) Utilize the cone crusher to crush the quartz ore raw material into quartz ore particles;

[0046] (4) Heat the quartz ore particles to 800-1000°C, specifically 800, 850, 900, 950 and 1000°C, which can cause sufficient expansion and deformation of the quartz ore particles, and then pour the quartz ore particles into water for cooling , resulting in a sufficiently large temp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com