Method for manufacturing official kiln imitated crackle glaze ceramic product

A cracked glaze, official kiln technology, applied in the production of imitation official kiln cracked glaze ceramic products, imitation official kiln cracked glaze field, can solve the problems of high potassium, sodium, easy cracking, large expansion coefficient, etc., to achieve high yield , crack uniformity, reduce the effect of thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

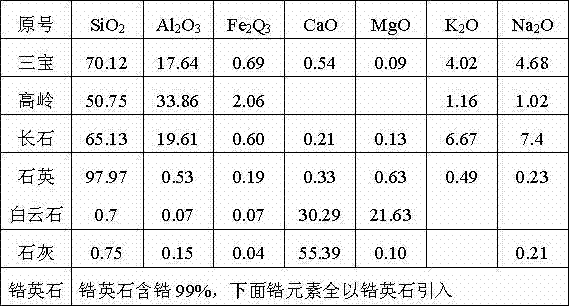

[0017] The weight percentage composition of the cracked glaze of the official kiln imitation:

[0018] Sambo 23% Feldspar 45% Kaolin 5% Quartz 15% Dolomite 5% Lime 5% Zircon 2%. After carefully selecting various glazes according to the requirements of the formula, mix them evenly, with a ball stone: glaze: water ratio of 2:1:0.8, put it into the ball milling equipment and grind to a fineness of 100 mesh after 16 hours of ball milling time, and filter The glaze slurry can be formed.

[0019] The chemical composition of the raw materials of the glaze

[0020]

Embodiment 1

[0021] Example 1 The ingredient weight percentage composition of imitating official kiln cracked glaze clay: Nangang billet 30%, Sanbao billet 10%, kaolin 30%, remaining dry billet 15%, and Qimen 15%. After beneficiation, beneficiation, crushing, elutriation, sedimentation, stale (slurry) 80 mesh fineness filtration, drainage and other processes, it becomes green mud.

[0022] The chemical composition of each raw material of the blank

[0023] Original numberSiO 2 Al 2 O 3 Fe 2 Q 3 CaO MgOK 2 O Na 2 O Nangang Billet73.2616.350.850.0.870.122.101.88 Sambo billet70.1317.640.690.540.094.024.68 Xingzi Gaoling50.7533.862.06 1.161.02 Yugan billet74.9414.930.990.530.455.902.27 Qimen Billet 73.9915.550.371.760.333.882.63

[0024] After forming the cracked porcelain body of the imitation official kiln, it is dried and loaded into the kiln. After 7 hours of low fire, the kiln temperature rises to 880℃ to stop firing, and the green body is discharged out of the kiln after natural coo...

Embodiment 2

[0027] Example The official kiln cracked glaze composition is composed of 20% Sambo, 40% feldspar, 10% kaolin, 10% quartz, 10% dolomite, 7% lime, and 3% zircon by weight. After carefully selecting various glazes according to the requirements of the formula, mix them evenly, with a ball stone: glaze: water ratio of 2:1:0.8, put it into the ball milling equipment and mill it into fine grinding for 16 hours and filter it into a glaze at 100 mesh. Pulp is enough.

[0028] The chemical composition of each raw material of the glaze is the same as in Example 1.

[0029] Example Imitating official kiln cracking and glaze clay batching weight percentage composition: Nangang billet 30%, Sambo billet 10%, kaolin 30%, remaining dry billet 15%, Qimen 15%, after beneficiation, selection, crushing, Elutriation, sedimentation, staleness (slurry), 80-mesh fine filtration, drainage and other processes become green mud.

[0030] The chemical composition of each raw material of the blank is the same a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com