High-strength high-toughness high-modulus deformed magnesium alloy and preparation method thereof

A deformed magnesium alloy, high modulus technology, applied in the field of non-ferrous metal materials and their processing, to achieve the effect of excellent mechanical properties and fine structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

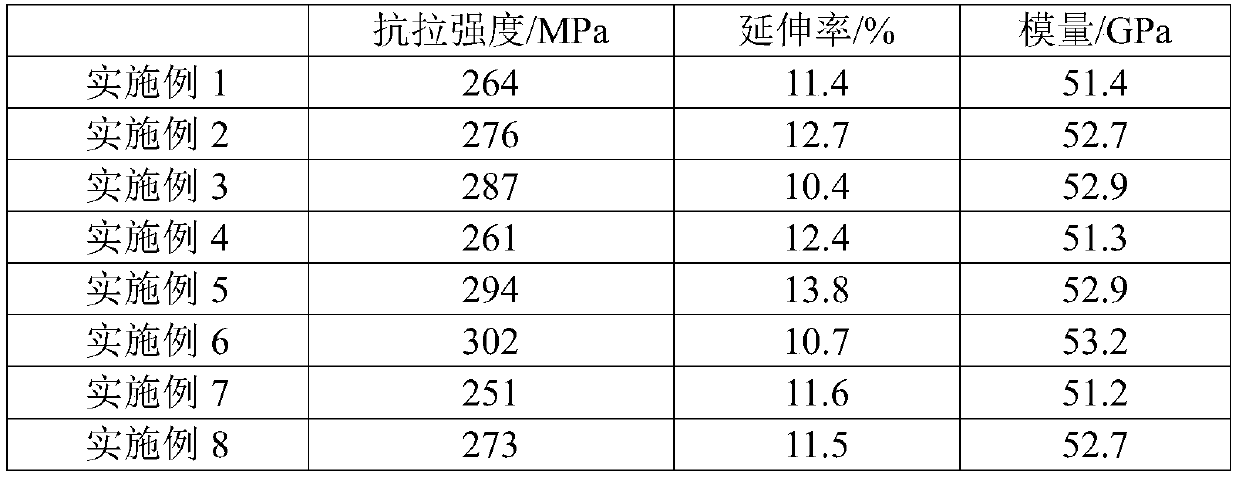

Examples

Embodiment 1

[0056] Alloy composition (mass percentage) of deformed magnesium alloy: 3.84% Al, 0.94% Ce, 1.12% La, 0.42% Sm, 0.25% Si, 0.50% Zn, 0.33% Mn, other unavoidable impurities are less than 0.2%, and the rest are Mg.

[0057] This embodiment relates to the smelting method of conventional rare earth magnesium alloy and the alloy deformation method in the present invention:

[0058] Among them, the smelting process is in SF 6 and CO 2 Under the condition of mixed gas protection, the steps are as follows:

[0059] Preheat the smelting raw materials at 200°C for 3 hours; put the dried pure magnesium into the SF 6 / CO 2 Melt in a gas-protected crucible resistance furnace; when the pure magnesium is completely melted and the temperature reaches 670°C, add preheated pure aluminum, pure zinc, magnesium-manganese master alloy; when the temperature rises to 720°C, add preheated magnesium Cerium master alloy, magnesium lanthanum master alloy, magnesium samarium master alloy, magnesium si...

Embodiment 2

[0064] Alloy composition (mass percentage) of high strength, toughness and high modulus deformed magnesium alloy: 3.79% Al, 1.14% Ce, 1.28% La, 0.42% Sm, 0.25% Si, 0.50% Zn, 0.30% Mn, other inevitable impurities are less than 0.2%, the rest is Mg.

[0065] This embodiment relates to the smelting method of conventional rare earth magnesium alloy and the alloy deformation method in the present invention:

[0066] Among them, the smelting process is in SF 6 and CO 2 Under the condition of mixed gas protection, the steps are as follows:

[0067] Preheat the smelting raw materials at 250°C for 2 hours; put the dried pure magnesium into the SF 6 / CO 2 Melt in a gas-protected crucible resistance furnace; when the pure magnesium is completely melted and the temperature reaches 680°C, add preheated pure aluminum, pure zinc, magnesium-manganese master alloy; when the temperature rises to 730°C, add preheated magnesium Cerium master alloy, magnesium-lanthanum master alloy, magnesium...

Embodiment 3

[0071] Alloy composition (mass percentage) of high strength, toughness and high modulus deformed magnesium alloy: 3.71% Al, 1.57% Ce, 1.71% La, 0.42% Sm, 0.25% Si, 0.50% Zn, 0.24% Mn, other inevitable impurities are less than 0.2%, the rest is Mg.

[0072] This embodiment relates to the smelting method of conventional rare earth magnesium alloy and the alloy deformation method in the present invention:

[0073] Among them, the smelting process is in SF 6 and CO 2 Under the condition of mixed gas protection, the steps are as follows:

[0074]Preheat the smelting raw materials at 250°C for 2 hours; put the dried pure magnesium into the SF 6 / CO 2 Melt in a gas-protected crucible resistance furnace; when the pure magnesium is completely melted and the temperature reaches 680°C, add preheated pure aluminum, pure zinc, magnesium-manganese master alloy; when the temperature rises to 730°C, add preheated magnesium Cerium master alloy, magnesium-lanthanum master alloy, magnesium-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com