Device and method for continuous preparation of large-size high-quality aluminum alloy cast ingots

An aluminum alloy ingot, high-quality technology, applied in the field of metal material processing, can solve the problems of composition segregation, coarse structure, cracks, etc., and achieve the effect of uniform temperature field and composition field, fine structure and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

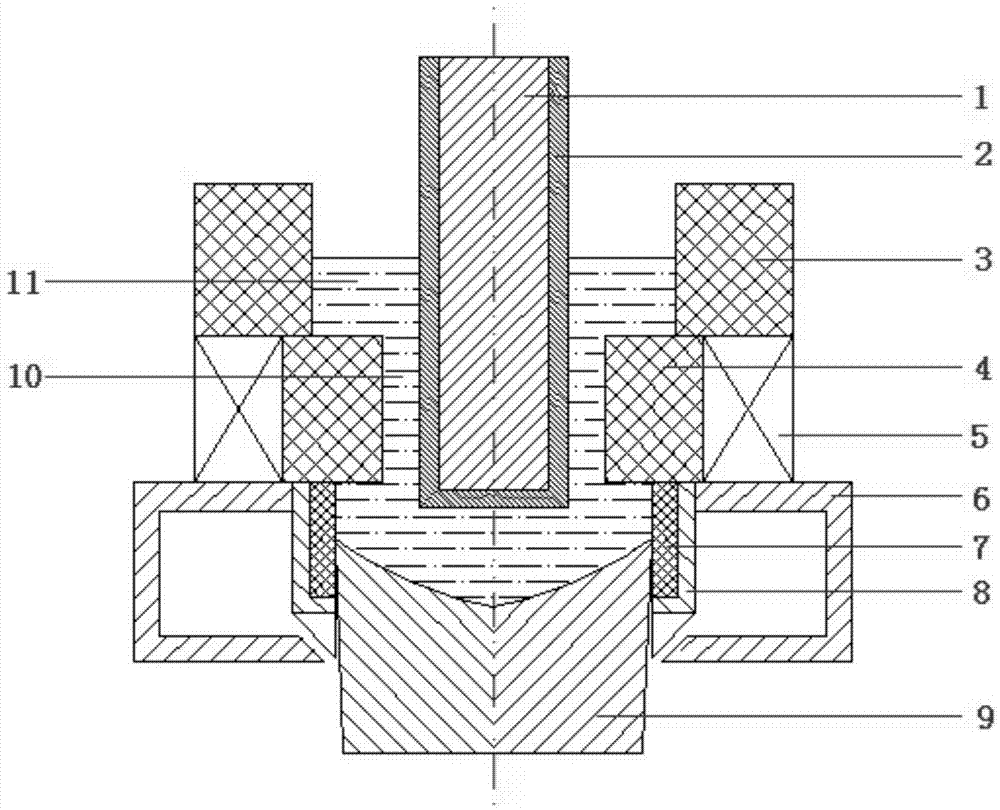

[0029] Such as figure 1 As shown, it is a schematic diagram of the device for continuously preparing large-size high-quality aluminum alloy ingots according to the present invention. Tube 4, electromagnetic stirrer 5, cooling water jacket 6, graphite ring 7 and crystallizer 8. The inside of the crystallizer 8 is inlaid with a graphite ring 7, the outside of the crystallizer 8 is provided with a cooling water jacket 6, the upper part of the crystallizer 8 is provided with a guide tube 4, the electromagnetic stirrer 5 is provided outside the guide tube 4, and the hot top 3 is provided on the On the upper part of the duct 4, the magnetic mandrel 1 is arranged at the heart of the duct 4, and the mandrel heat insulation sleeve 2 is installed on the periphery of the magnetic mandrel 1, between the magnetic mandrel 1 and the inner wall of the duct 4 A narrow slot channel 10 is formed.

[0030] In the continuous ingot casting device, the magnetically permeable mandrel 1 is made of a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com