Technology for processing test blanket module (TBM) first wall U-shaped flow-containing cooling pipeline set

A technology for cooling pipes and processing technology, applied in the field of mechanical processing, can solve problems such as deformation mechanical properties, decline, etc., to achieve the effects of improving strength and toughness, low radioactivity, and reducing material waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of processing technology of first wall U-shaped flow-containing cooling pipe group test piece, this technology comprises the following steps:

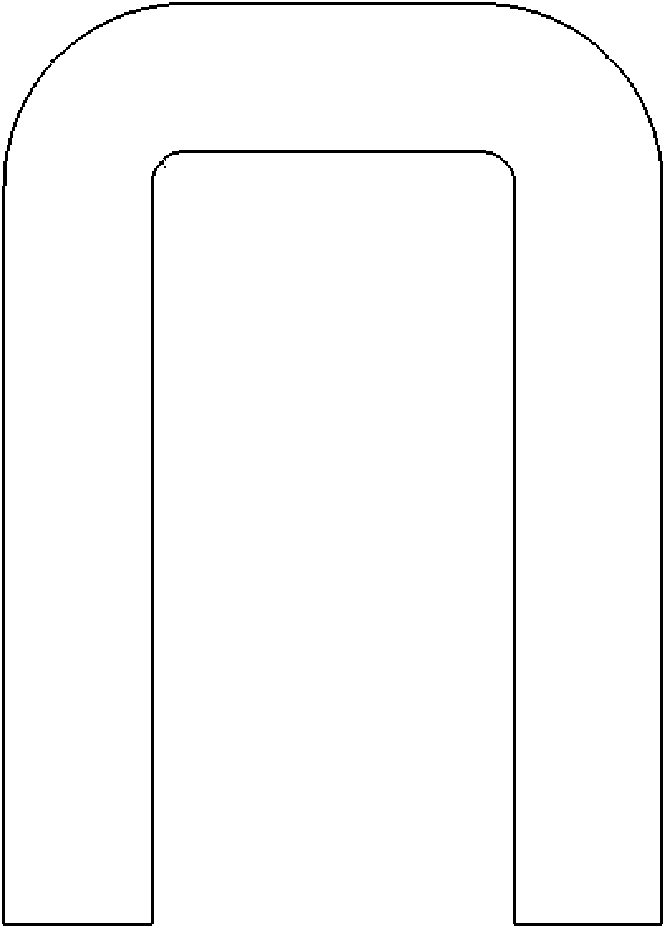

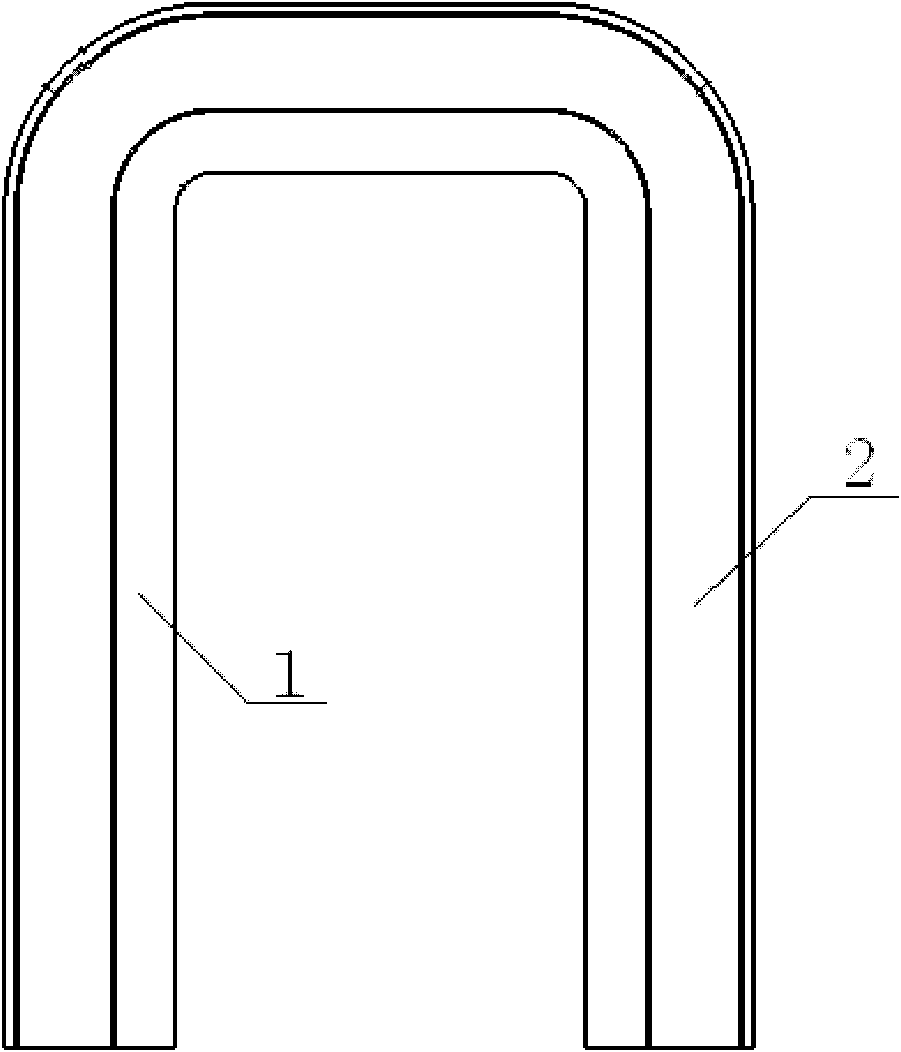

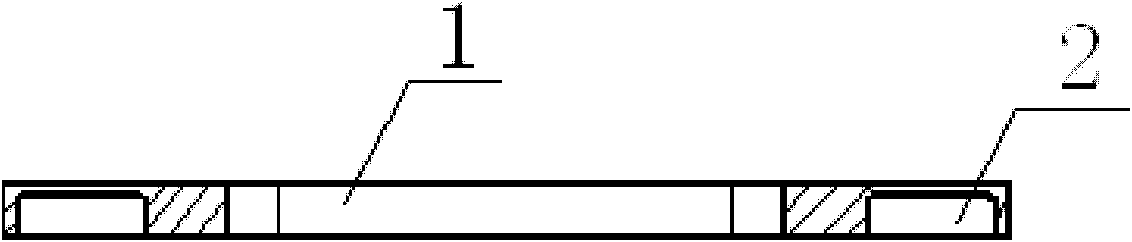

[0028] Step 1: select the spherical powder based on the CLF-1 chemical composition formula of the Southwest Institute of Physics of the Nuclear Industry, and use the laser stereoforming process to process it into such figure 1 The unslotted U-shaped frame sub-assembly 1 is shown. The specific way is to use the laser stereoforming manufacturing equipment model LSF-III, first generate a three-dimensional CAD model of the U-shaped frame component 1 in the computer, and then "slice" the model in layers with a certain thickness of 0.5mm, that is, The three-dimensional data information of the U-shaped frame component 1 is converted into a series of two-dimensional contour information, and then the laser cladding method is used to accumulate materials layer by layer according to the contour trajectory, and finally forms such as ...

Embodiment 2

[0034] Manufacture the first wall U-shaped flow-containing cooling pipe group according to the same processing technology as in Example 1, the difference is that:

[0035] (1) The spherical powder of the low-activation ferrite / martensitic steel used in step one is based on the CLAM chemical composition formula of the Institute of Plasma, Chinese Academy of Sciences;

[0036] (2) In step 3, use a VacBond type high-frequency induction heating vacuum diffusion welding machine to butt two U-shaped frame components 1 with U-shaped grooves 2 into a U-shaped cooling pipe 3 .

[0037] The mechanical properties (including strength and toughness) of the structural material of the U-shaped flow-containing cooling pipe group on the first wall of the TBM obtained in this implementation have been significantly improved. The tensile strength at room temperature reaches 750MPa, the yield strength reaches 650MPa, and the reduction of area reaches 20%; material consumption is less than 20% of t...

Embodiment 3

[0039] Manufacture the first wall U-shaped flow-containing cooling pipe group test piece according to the same processing technology as Example 1, the difference is that the spherical powder of low activation ferrite / martensitic steel used in step 1 is based on Eurofer97 in Europe Chemical composition formula.

[0040] The mechanical properties (including strength and toughness) of the structural material of the U-shaped flow-containing cooling pipe group on the first wall of the TBM obtained in this implementation have been significantly improved. The tensile strength at room temperature reaches 750MPa, the yield strength reaches 650MPa, and the reduction of area reaches 20%; material consumption is less than 20% of traditional machining process,

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com