Water-based crack sandstone paint and preparation method thereof

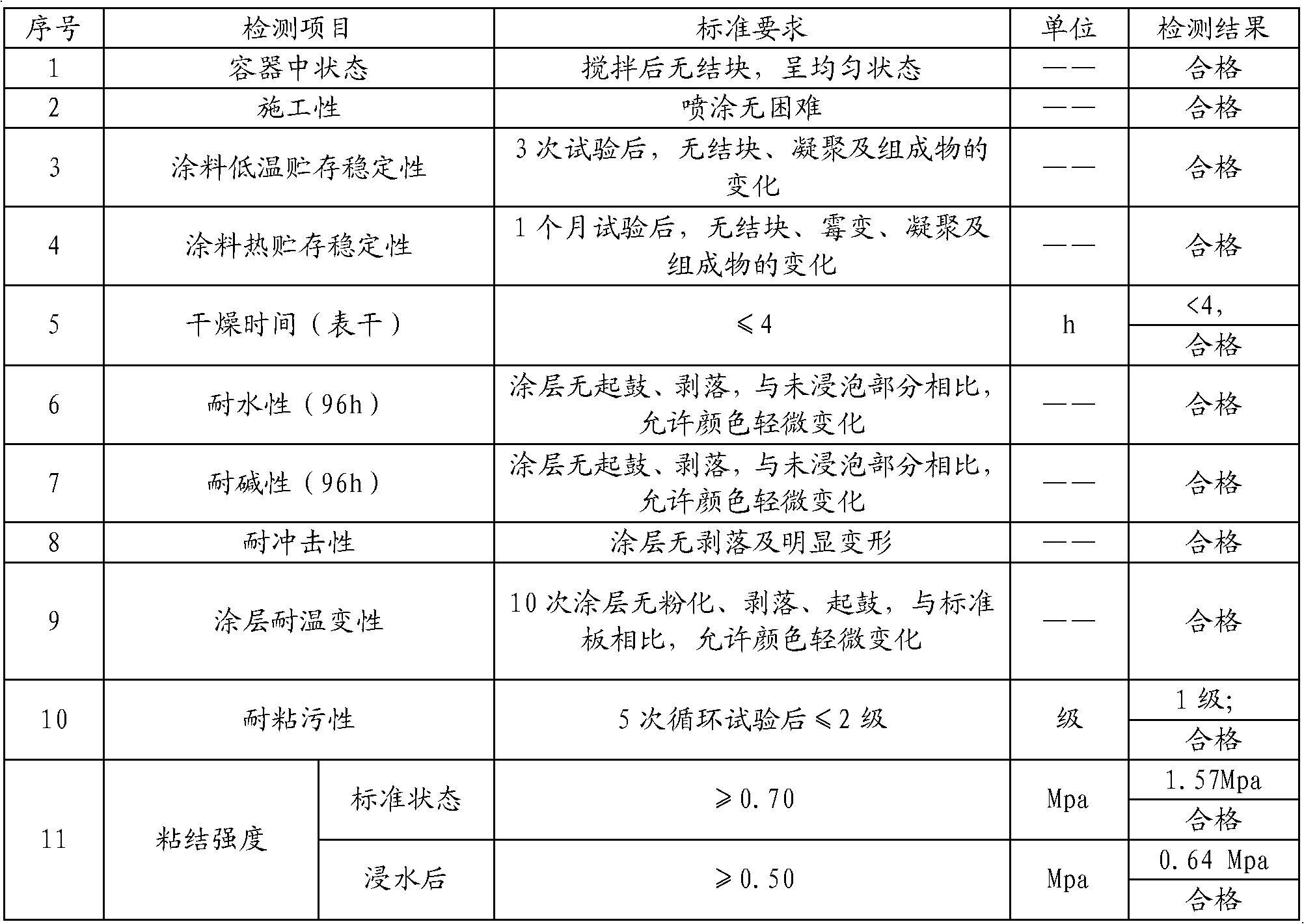

A crack and sandstone technology, which is applied in the field of water-based crack sandstone paint and its preparation, can solve the problems of poor stability, easy peeling, and non-durability, and achieve the effects of strong viscosity and adsorption, convenient and fast use, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

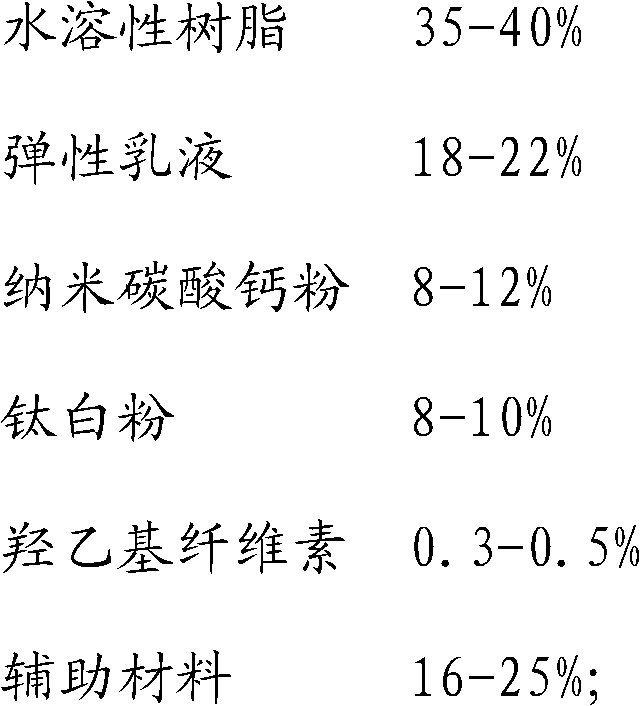

[0031] Formula (by mass percentage):

[0032] a) Primer composition:

[0033] Arabic resin 35%, elastic emulsion 22%, nano calcium carbonate powder 12%, titanium dioxide 10%, hydroxyethyl cellulose 0.5%, dispersant 0.5%, wetting agent 1.5%, bactericidal and antifungal agent 1%, film-forming aid Agent 1%, ethylene glycol 1%, alkali-soluble thickener 2.5%, deionized water 13%.

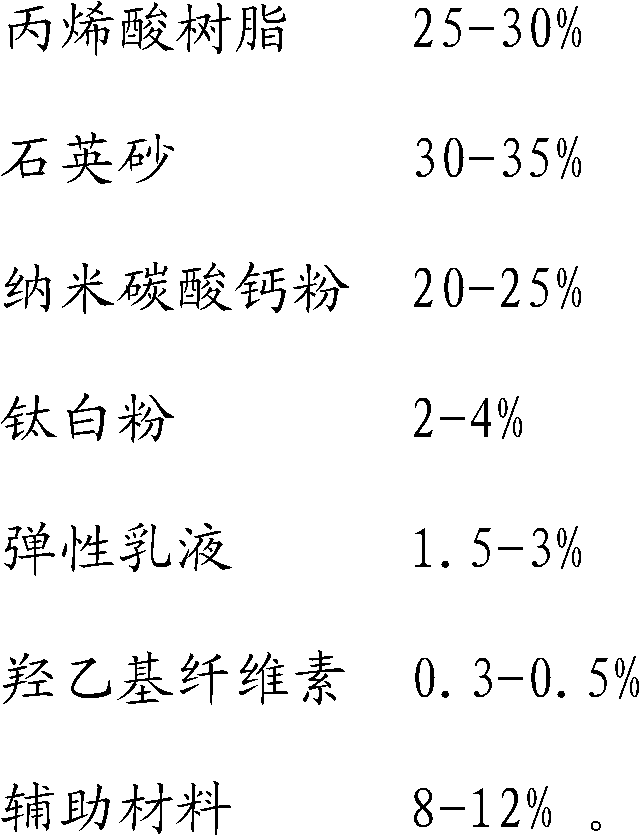

[0034] b) Topcoat composition:

[0035] Acrylic resin 30%, quartz sand 35%, nano calcium carbonate powder 20%, titanium dioxide 4%, elastic emulsion 1.5%, hydroxyethyl cellulose 0.5%, film-forming aid 1%, ethylene glycol 0.7%, dispersant 1%, defoamer 1%, bactericide antifungal agent 0.3%, deionized water 5%.

[0036] Preparation:

[0037] 1) Preparation of the primer composition: take 80% of the deionized water in the formula in a container, put Arabic resin, nano calcium carbonate powder and titanium dioxide into the deionized water under high-speed dispersion conditions, and continue high-speed dis...

Embodiment 2

[0045] Formula (by mass percentage):

[0046] a) Primer composition:

[0047] Arabic resin 40%, elastic emulsion 20%, nano calcium carbonate powder 10%, titanium dioxide 8%, hydroxyethyl cellulose 0.3%, dispersant 2%, wetting agent 3%, bactericidal and antifungal agent 0.5%, film-forming aid Agent 2%, ethylene glycol 1.2%, alkali-soluble thickener 1.5%, deionized water 11.5%.

[0048] b) Topcoat composition:

[0049] Acrylic resin 25%, quartz sand 30%, nano calcium carbonate powder 25%, titanium dioxide 4%, elastic emulsion 3%, hydroxyethyl cellulose 0.5%, film-forming aid 1.5%, ethylene glycol 1%, dispersant 0.5%, defoamer 1%, bactericide and antifungal agent 1.5%, deionized water 7%.

[0050] Preparation:

[0051]1) Preparation of the primer composition: take 80% of the deionized water in the formula in a container, put arabic resin, nano calcium carbonate powder and titanium dioxide into the deionized water under high-speed dispersion conditions, and continue high-speed...

Embodiment 3

[0054] Formula (by mass percentage):

[0055] a) Primer composition:

[0056] Arabic resin 40%, elastic emulsion 18%, nano calcium carbonate powder 8%, titanium dioxide 10%, hydroxyethyl cellulose 0.5%, dispersant 2%, wetting agent 3%, bactericidal and antifungal agent 1%, film-forming aid Agent 3.5%, ethylene glycol 1.5%, alkali-soluble thickener 2.5%, deionized water 10%.

[0057] b) Topcoat composition:

[0058] Acrylic resin 28%, quartz sand 33%, nano calcium carbonate powder 22%, titanium dioxide 2%, elastic emulsion 2%, hydroxyethyl cellulose 0.3%, film-forming aid 1.5%, ethylene glycol 0.7%, dispersant 1%, defoamer 0.5%, bactericidal antifungal agent 2%, deionized water 7%.

[0059] Preparation:

[0060] 1) Preparation of the primer composition: take 80% of the deionized water in the formula in a container, put Arabic resin, nano-calcium carbonate powder and titanium dioxide into the deionized water under the condition of high-speed dispersion, and continue high-spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com