Post-pouring functional zone combined track beam

A technology of functional areas and track beams, applied in the field of track beams, can solve problems such as increased noise, poor finish, and difficult construction, and achieve the effects of reducing load-bearing capacity requirements, changing noise directivity, and facilitating processing and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

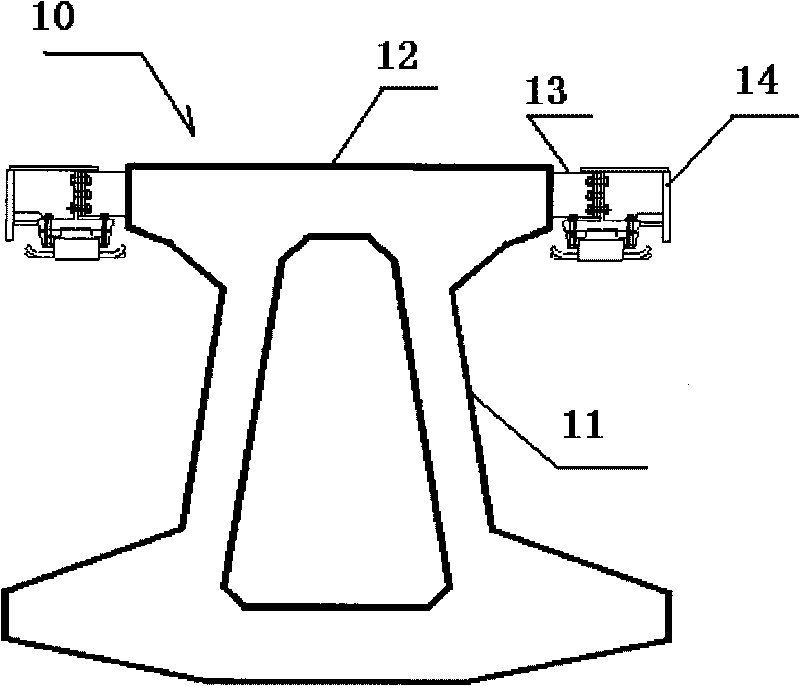

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

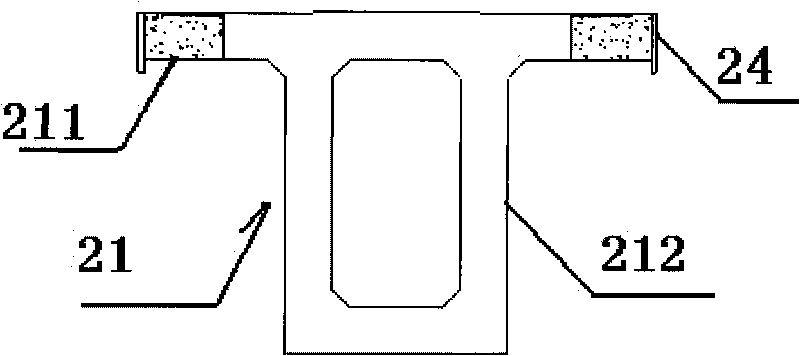

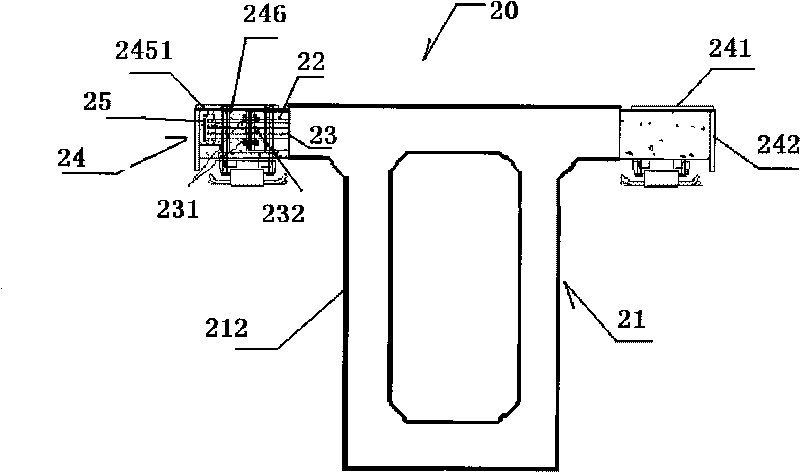

[0024] For the specific implementation of the post-cast functional area combined with the track beam 20 of the present invention, please refer to figure 2 and image 3 As shown, the support beam 21 is composed of post-cast functional areas 211 on both sides of the upper flange and an upright web 212 vertically arranged at the bottom of the support beam 21; The connecting piece 23; the two sides of the support beam 21 are respectively provided with steel functional parts 24; the transverse insertion bars 22 are inserted into the steel functional parts 24; the support beam 21 and the steel functional parts 24 are connected by bolts.

[0025] The first part is the prestressed concrete support beam 21, and the transverse ribs 22 protrude from the cantilever on both sides of the upper flange. It is vertically arranged at the lower part of the support beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com