Double-input and double-output wheel-sided transmission assembly

A dual-input, dual-output, transmission technology, which is applied in transportation and packaging, motion deposition, control devices, etc., can solve the problems of high cost and large motor torque requirements, and achieve lower load-carrying capacity requirements, flexible forward and reverse rotation, and independent speed controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

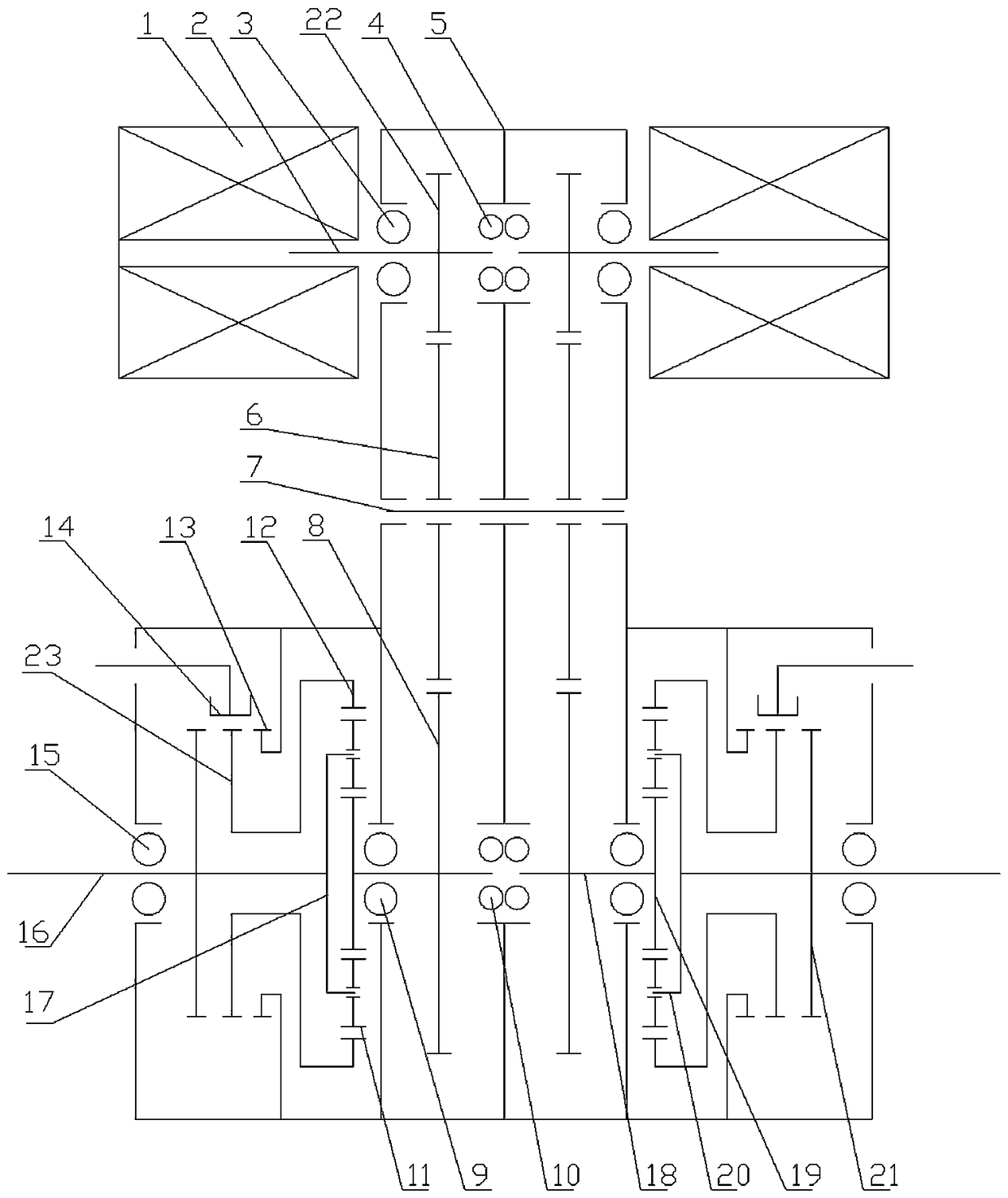

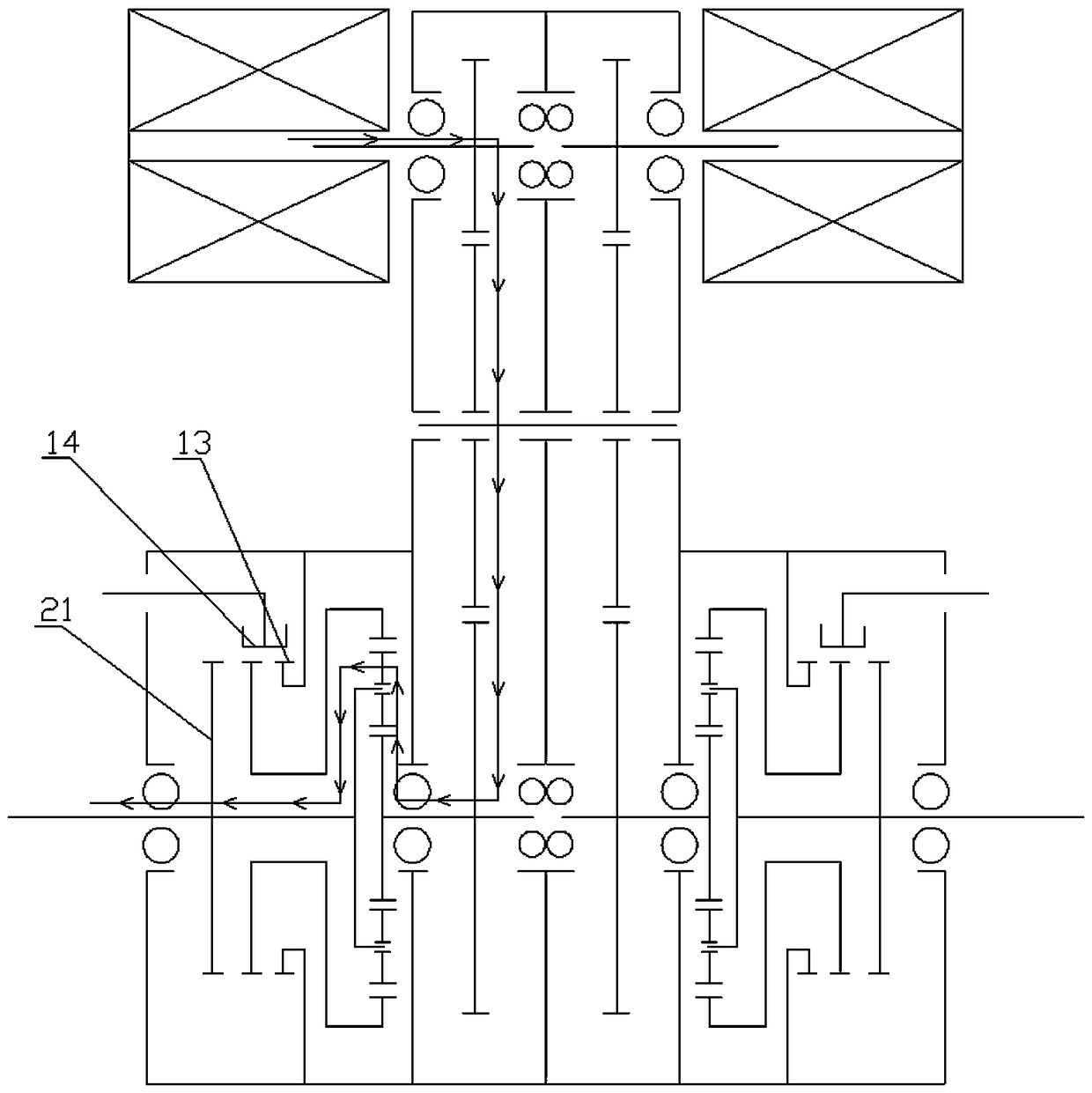

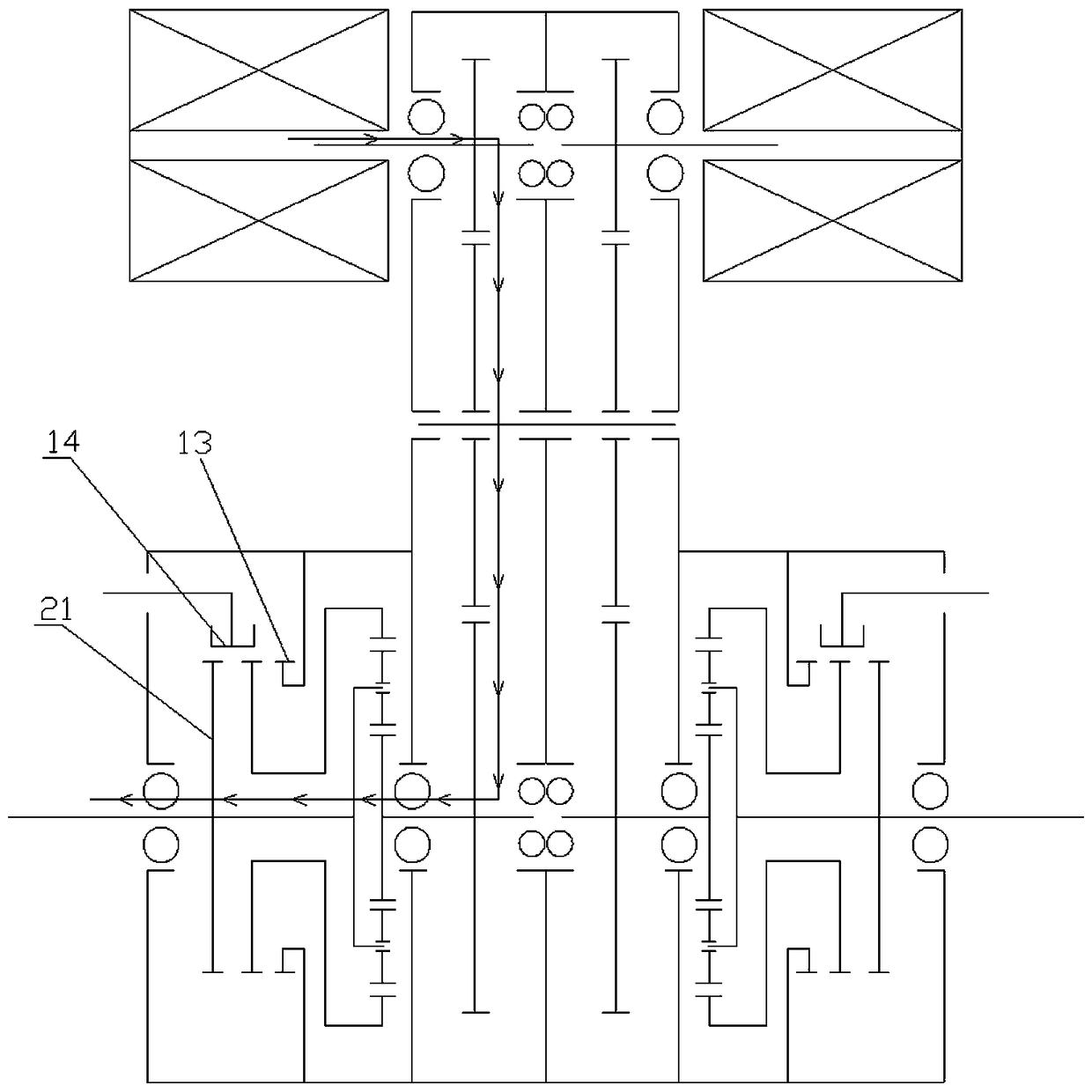

[0021] see Figure 1 to Figure 3, a double-input double-output wheel-side transmission assembly, characterized in that: it includes a transmission housing 5, and the left and right sides of the transmission housing 5 are respectively symmetrically provided with a power input shaft 2, a power output shaft 16 and a planetary mechanism, The axis lines of the two power input shafts 2 are located on the same straight line, and the axis lines of the two power output shafts 16 are located on the same line. Stretch out transmission case 5, be used to drive left and right wheels respectively, the other end of two power take-off shafts 16 is fixedly connected with the planet carrier 17 of planetary mechanism on the left and right sides of transmission case 5 respectively, and described power take-off shaft 16 is provided with There is an output shaft gear 21, and a low gear 13 is fixed on the transmission case 5, and a high and low gear seat 23 is arranged between the output shaft gear ...

Embodiment 2

[0028] The input shaft gear 22 on the power input shaft 2 meshes with the sun gear input gear 8 on the sun gear input shaft 18 through the idler gear 6, and the idler gear 6 is sleeved on the idler shaft 7, and the idler shaft 7 supports on the transmission case 5. The idler shaft 7 is parallel to the power input shaft 2 and the sun gear input shaft 18, and the left and right ends of the idler shaft 7 are respectively provided with an idler 6, and the idler 6 and the idler shaft 7 are slidably fitted and axially positioned , the idler gear 6 at the left end of the idler shaft 7 meshes with the input shaft gear 22 on the power input shaft 2 on the left side of the transmission housing 5, and the idler gear 6 at the left end of the idler shaft 7 is input to the sun gear on the left side of the transmission housing 5 The sun gear input gear 8 on the shaft 18 meshes; the idler gear 6 on the right end of the idler shaft 7 meshes with the input shaft gear 22 on the power input shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com