Ultrasonic suspension guide rail with high positioning precision

A guide rail and ultrasonic technology, which is applied to the suspension device of the wing leaf, the control mechanism of the wing leaf, door/window fittings, etc. High, low pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

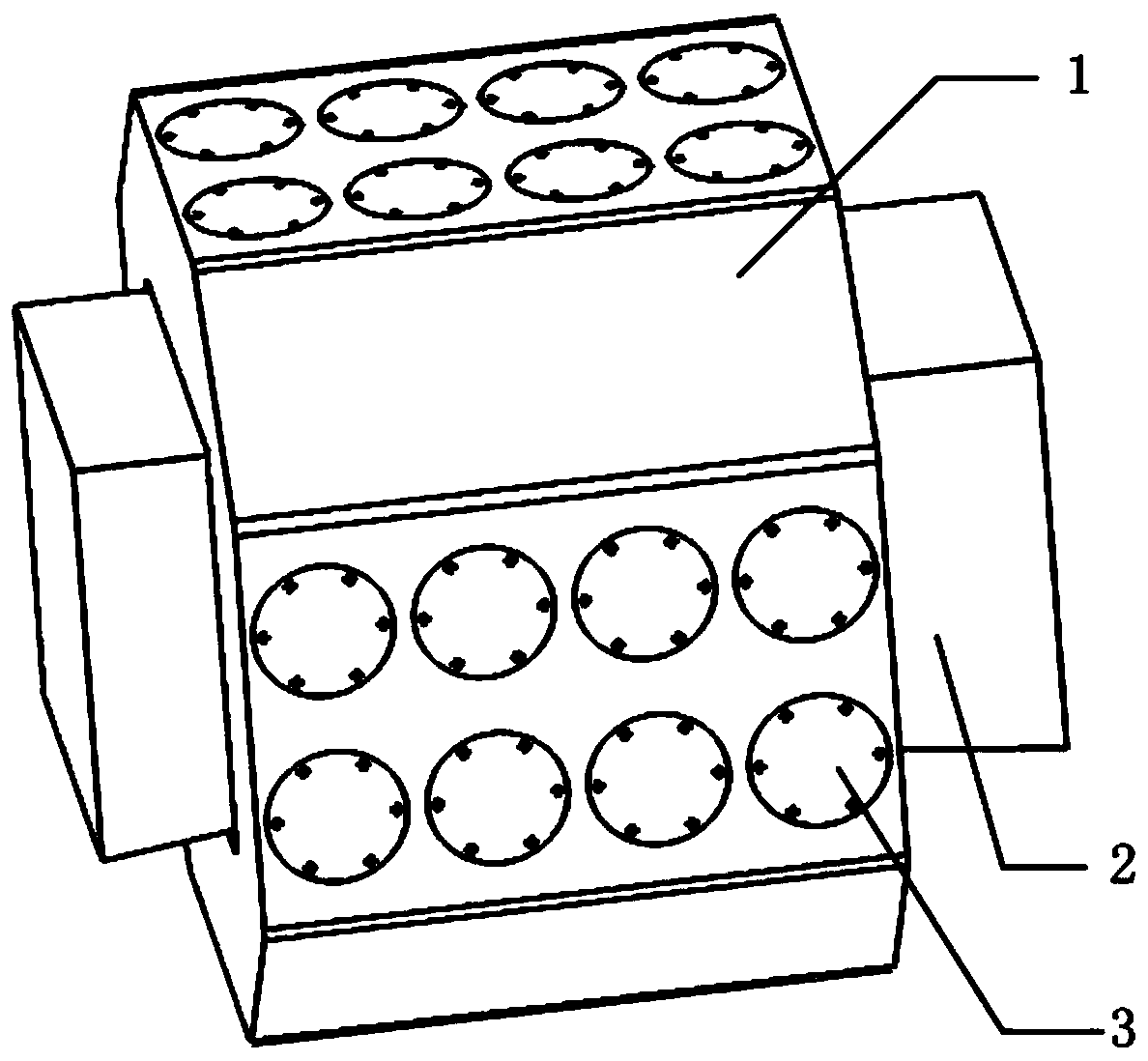

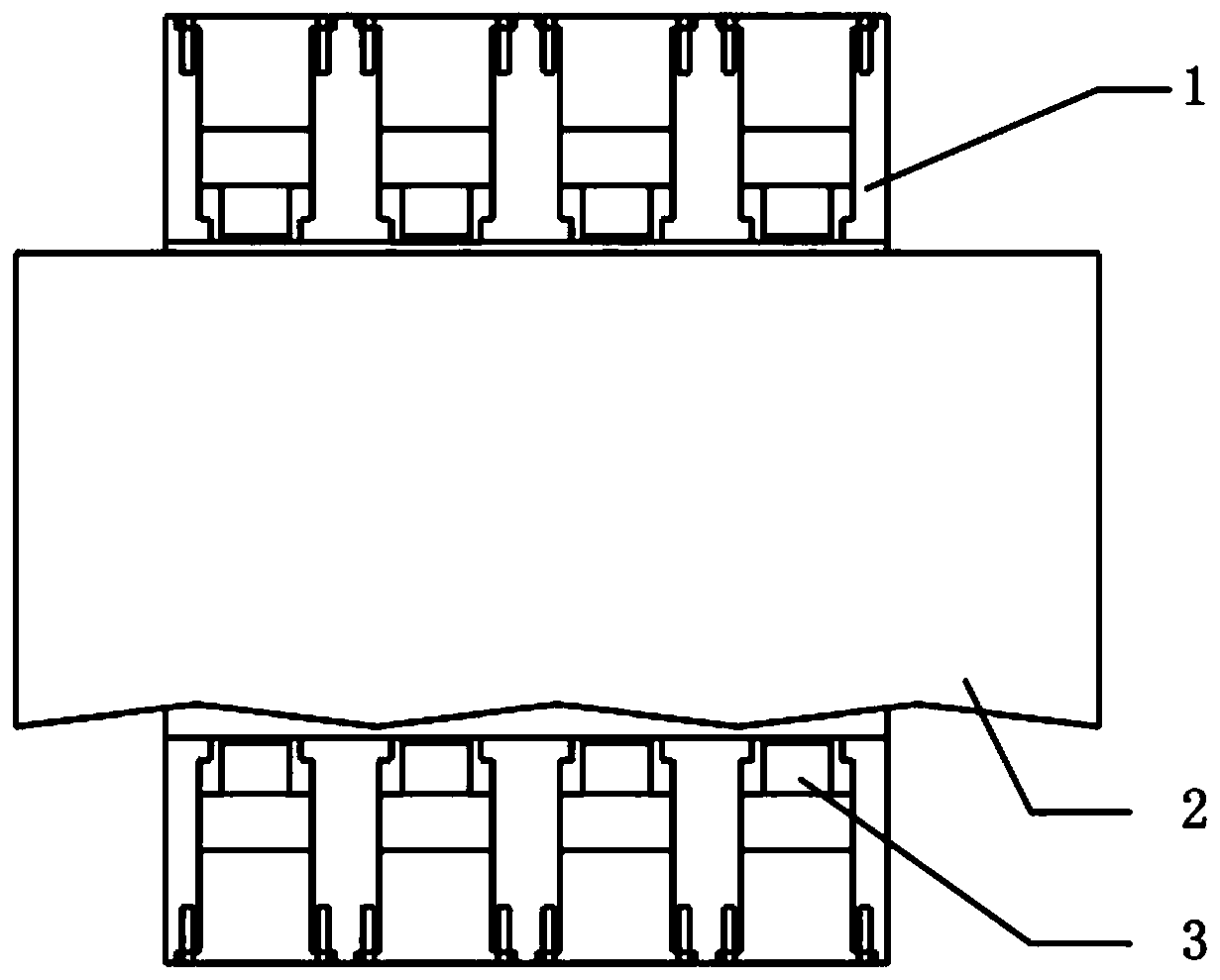

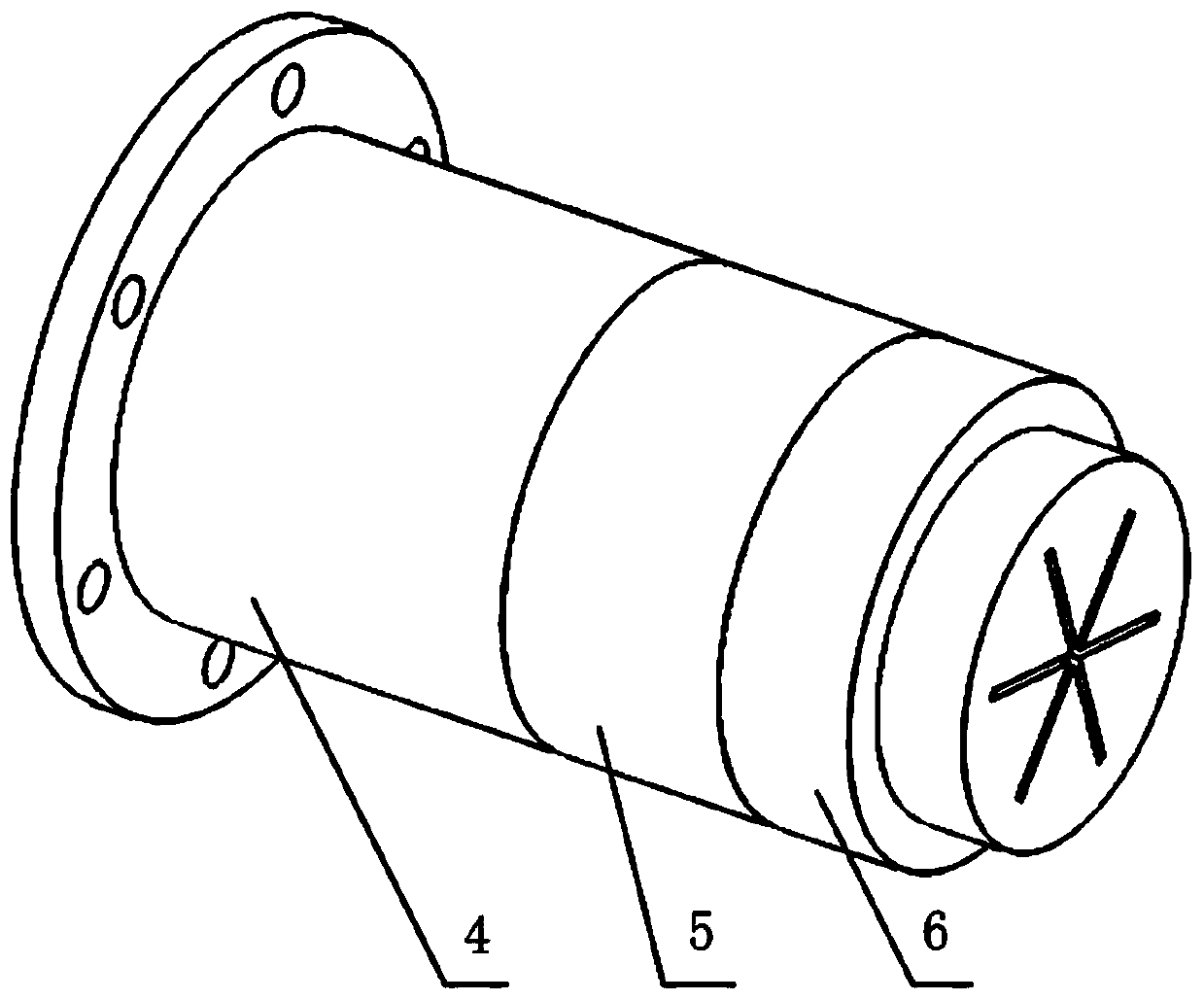

[0031] In the figure, 1. transducer bracket, 2. guide rail, 3. piezoelectric transducer, 4. rear end cover, 5. ceramic piezoelectric sheet, 6. horn.

[0032] Such as figure 1 As shown, the specific implementation of the present invention includes piezoelectric transducer 3, guide rail 2 and transducer support 1; The bracket 1 is set outside the guide rail 2, the central axis of the guide rail 3 coincides with the central axis of the piezoelectric transducer bracket, and there is a gap between the inner peripheral surface of the transducer bracket 1 and the outer circumference of the guide rail 2; the upper, lower and both sides of the transducer bracket 1 There are evenly distributed circular through-holes with the same size on the four surfaces, and the through-holes are divided into upper and lower rows, four in each row, and the distance between adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com