Sludge treatment device

A technology of sludge treatment and treatment cylinder, applied in the direction of sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve air and environmental pollution, the overall technical route of national sludge treatment and disposal is not clear enough, Problems such as not being properly dealt with can achieve the effect of overcoming secondary pollution and alleviating the contradiction between sludge production and sludge treatment capacity lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

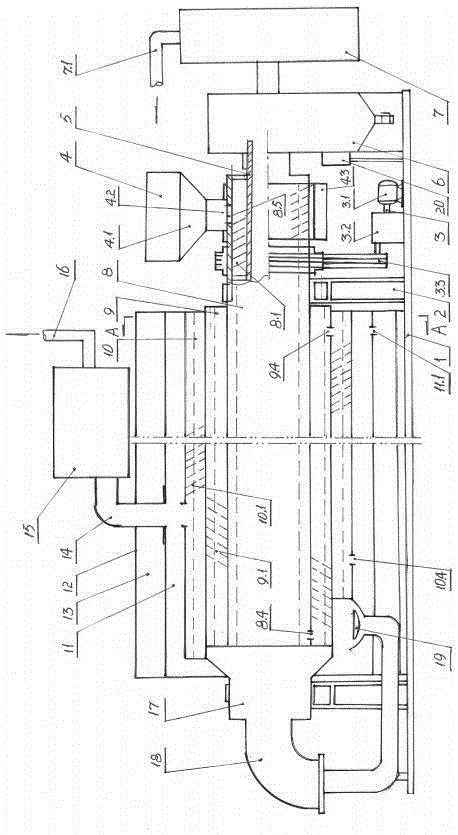

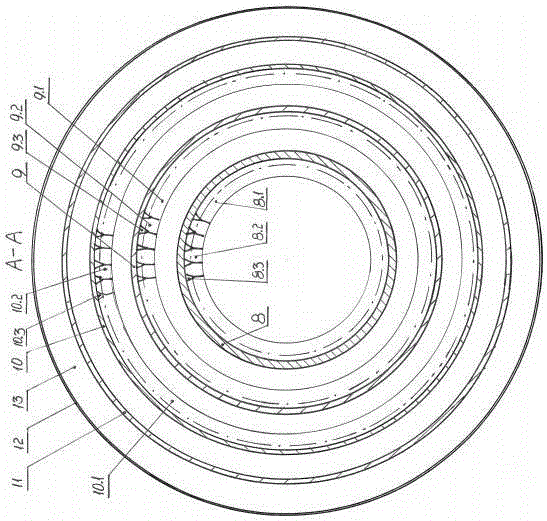

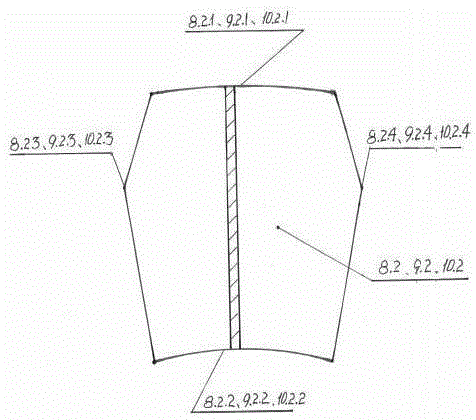

[0028] A kind of sludge treatment device of embodiment 1 of the present invention (see figure 1 , figure 2 , image 3 ), including machine base 1, sludge treatment drums 8, 9, 10, 11, power drive mechanism 3, output pipelines 5, 14, 18 and machine cover 12, and the sludge treatment device described in it includes heavy metal treatment drums 8. The carbonization drum 9 and the fixed carbon combustion drum 10 are composed of three coaxial sets from the inside to the outside. The helixes 8.1, 9.1, and 10.1 on the inner side of the cylinder are arranged opposite to each other, and the cylinder at the end of the helix 8.1, 9.1, and 10.1 The wall is provided with discharge port 8.4, 9.4, 10.4 of the sludge treatment drum constituted by the spiral drum, the two ends of the drum are respectively provided with a supporting device 2; the heavy metal processing drum 8 of the sludge processing drum and the carbonization drum 9 form a The dislocation structure is set, and a power drive ...

Embodiment 2

[0037] A kind of sludge treatment device of embodiment 2 of the present invention (see figure 1 , figure 2 , image 3 ), including machine base 1, sludge treatment drums 8, 9, 10, 11, power drive mechanism 3, output pipelines 5, 14, 18 and machine cover 12, and the sludge treatment device described in it includes heavy metal treatment drums 8. The carbonization drum 9 and the fixed carbon combustion drum 10 are composed of three coaxial sets from the inside to the outside. The helixes 8.1, 9.1, and 10.1 on the inner side of the cylinder are arranged opposite to each other, and the cylinder at the end of the helix 8.1, 9.1, and 10.1 The wall is provided with discharge port 8.4, 9.4, 10.4 of the sludge treatment drum constituted by the spiral drum, the two ends of the drum are respectively provided with a supporting device 2; the heavy metal processing drum 8 of the sludge processing drum and the carbonization drum 9 form a The dislocation structure is set, and a power drive ...

Embodiment 3

[0046] A kind of sludge treatment device of embodiment 3 of the present invention (see figure 1 , figure 2 , image 3 ), including machine base 1, sludge treatment drums 8, 9, 10, 11, power drive mechanism 3, output pipelines 5, 14, 18 and machine cover 12, and the sludge treatment device described in it includes heavy metal treatment drums 8. The carbonization drum 9 and the fixed carbon combustion drum 10 are composed of three coaxial sets from the inside to the outside. The helixes 8.1, 9.1, and 10.1 on the inner side of the cylinder are arranged opposite to each other, and the cylinder at the end of the helix 8.1, 9.1, and 10.1 The wall is provided with discharge port 8.4, 9.4, 10.4 of the sludge treatment drum constituted by the spiral drum, the two ends of the drum are respectively provided with a supporting device 2; the heavy metal processing drum 8 of the sludge processing drum and the carbonization drum 9 form a The dislocation structure is set, and a power drive me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com