Full-armor mud discharging pipe, production method and special device of full-armor mud discharging pipe

A production method and technology of mud discharge pipe, applied in the production method and its special device, related equipment used in dredging engineering, and the field of full-armor mud discharge pipe, can solve the problem of matching difficult metal composite mud discharge pipe and wear resistance of inner pipe wall In order to achieve the effect of highlighting substantive features, novel design concepts and meeting bending requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

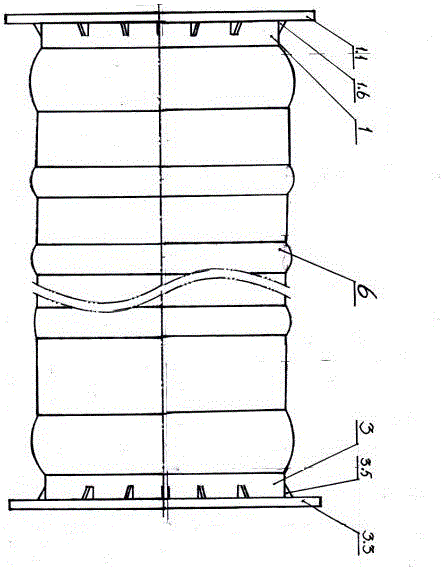

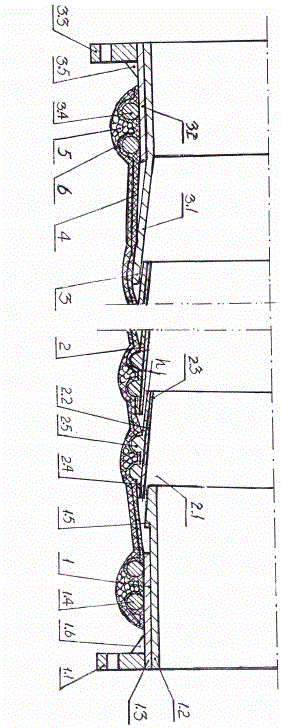

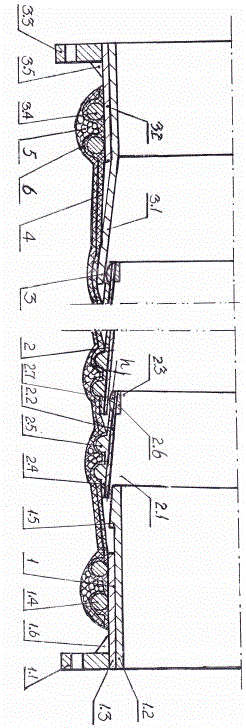

[0037] A kind of full armor mud discharge pipe of embodiment 1 of the present invention (referring to figure 1 , figure 2 ), including the pipe body and the connecting fastening layer compounded on the outside of the pipe body, including that the pipe body is an inlet end pipe 1 with a flange, 5 tapered pipes 2, and an outlet end with a flange The connecting pipe 3 is sequentially assembled into one piece of armor, and its inlet pipe 1, tapered pipe 2, and outlet pipe 3 are composited by inner steel pipes 1.2, 2.2, 3.1, outer steel pipes 1.3, 2.4, 3.2, and inner steel pipes 1.2 , 2.2, and 3.1 are wear-resistant layers, and the wear-resistant high-chromium cast iron pipes made of wear-resistant high-chromium cast iron materials are used. The outer steel pipes 1.3, 2.4, and 3.2 are reinforced layers, which are made of ordinary low-carbon steel plates through batching, blanking, and pressing. A low-carbon steel pipe structure prepared by molding and welding processes. The inle...

Embodiment 2

[0048] A kind of full armor mud discharge pipe of embodiment 2 of the present invention (referring to figure 1 , image 3 ), including the pipe body and the connecting fastening layer compounded on the outside of the pipe body, the pipe body is an inlet end pipe 1 with a flange, 8 tapered pipes 2, and an outlet end with a flange The connecting pipe 3 is sequentially assembled into one piece of armor, and its inlet pipe 1, tapered pipe 2, and outlet pipe 3 are composited by inner steel pipes 1.2, 2.2, 3.1, outer steel pipes 1.3, 2.4, 3.2, and inner steel pipes 1.2 , 2.2, and 3.1 are wear-resistant layers, which are 2-layer composite wear-resistant high-chromium cast iron pipes made of wear-resistant high-chromium cast iron materials, and outer steel pipes 1.3, 2.4, and 3.2 are reinforced layers, which are made of ordinary low-carbon steel Steel Pipe. The inlet end connection pipe 1 is composed of an inner steel pipe 1.2 and an outer layer steel pipe 1.3, and an inlet end conn...

Embodiment 3

[0060] A kind of full armor mud discharge pipe of embodiment 3 of the present invention (referring to figure 1 , image 3 ), including the pipe body and the connecting fastening layer compounded on the outside of the pipe body, the pipe body is an inlet end pipe 1 with a flange, 10 tapered pipes 2, and an outlet end with a flange The connecting pipe 3 is sequentially assembled into one piece of armor, and its inlet pipe 1, tapered pipe 2, and outlet pipe 3 are composited by inner steel pipes 1.2, 2.2, 3.1, outer steel pipes 1.3, 2.4, 3.2, and inner steel pipes 1.2 , 2.2, and 3.1 are wear-resistant layers, which are wear-resistant high-chromium cast iron pipes prepared by using wear-resistant steel plates through the process of batching, blanking, pressing, and welding. The outer steel pipes 1.3, 2.4, and 3.2 are reinforcement layers. Ordinary spiral low carbon steel pipe coil. The inlet end connection pipe 1 is composed of an inner steel pipe 1.2 and an outer layer steel pip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com