Method for adsorbing and removing ammonia and nitrogen in wastewater by zeolite and adsorption denitrification device

An adsorption denitrification, adsorption device technology, applied in adsorption water/sewage treatment, chemical instruments and methods, natural water treatment, etc., can solve the problems of reducing the total nitrogen treatment load, difficult to reach the standard of total nitrogen depth, etc., to reduce consumption , high adsorption efficiency, simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a small-scale test method and device for removing ammonia nitrogen in wastewater by dynamic zeolite adsorption.

[0039] Experimental material: Liaoning Beipiao natural clinoptilolite was selected as the experimental material, with a density of 1.97g / cm 3 , bulk density 0.96g / cm 3 , porosity 40%-55%, silicon-aluminum ratio 4.10-4.22. Use a sieve to screen out zeolites with particle sizes of 0.5-1.5mm, 1.5-2.5mm, 2.5-3.5mm, and 3.5-4.5mm, wash them with ultrapure water, and dry them for later use. The elemental composition of this natural zeolite is shown in Table 1, and the scanning (BEM) photograph of physical figure and surface is shown in respectively figure 1 with figure 2 .

[0040] Table 1

[0041] element

C

O

Na

Mg

Al

Si

K

Ca

Fe

content(%)

14.92

0.27

0.31

0.76

4.24

15.86

0.45

2.93

0.33

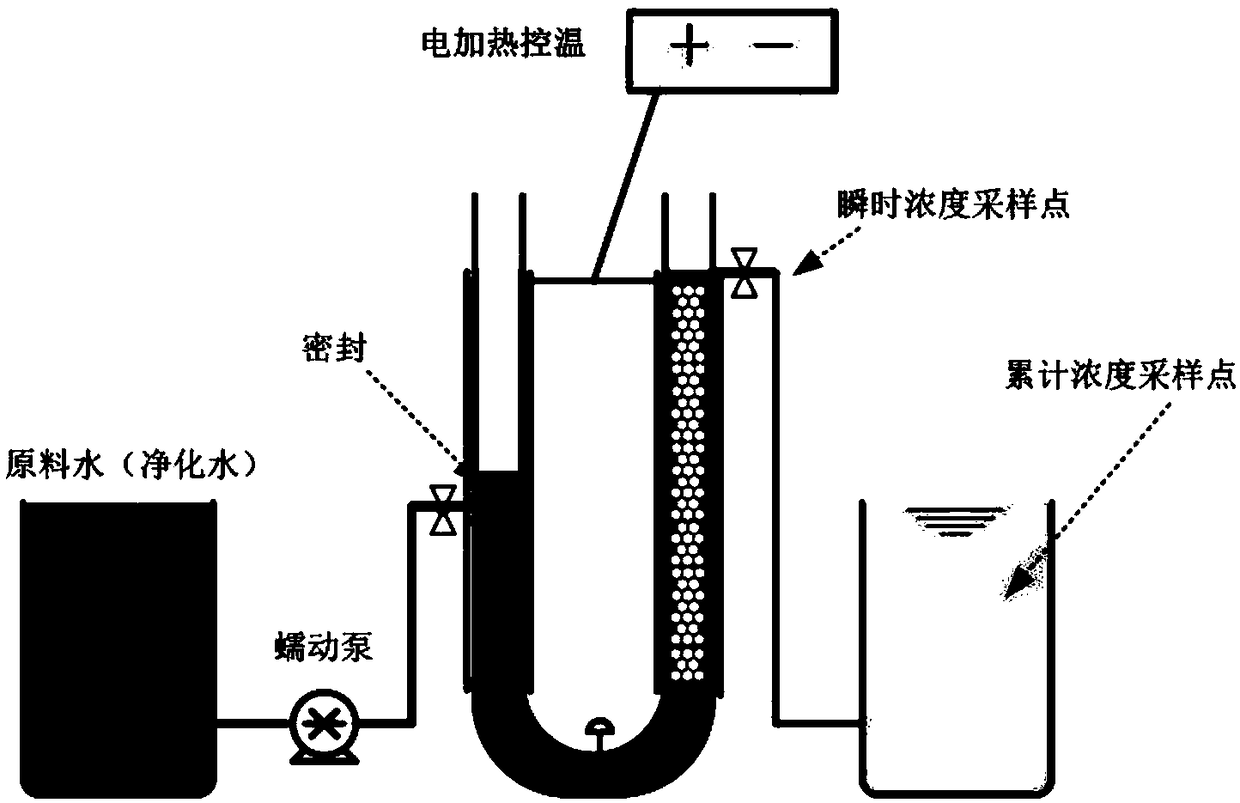

[0042] The device used in this dynamic adsorption experiment is as...

Embodiment 2

[0045] This embodiment provides a pilot test method and device for removing ammonia nitrogen in wastewater by dynamic zeolite adsorption.

[0046] Experimental material: the zeolite of Example 1 was selected as the experimental material. The device used in this dynamic adsorption pilot experiment is as follows: Figure 4 shown.

[0047]Zeolite regeneration conditions are the key to the zeolite adsorption denitrification method. The conditions of zeolite regeneration determined in the laboratory are difficult to simulate the working conditions of industrial equipment. Therefore, the pilot plant constructed in this example is mainly used to determine the regeneration conditions and regeneration conditions of zeolite. The final adsorption capacity provides scientific data support for the industrial application of this technology. Such as Figure 4 As shown, the inner diameter of the adsorption column is D=350mm, the total height is 3300mm, the effective height is 2.75m (the ra...

Embodiment 3

[0049] This embodiment studies the main factors affecting the adsorption and desorption of ammonia nitrogen by zeolite. The specific experiments are as follows:

[0050] ① Static adsorption experiment

[0051] Content 1: The effect of zeolite particle size on the adsorption effect was studied:

[0052] Weigh 10g of zeolite with different particle sizes (0.5-1.5mm, 1.5-2.5mm, 2.5-3.5mm, 3.5-4.5mm) into a 500ml Erlenmeyer flask, add 200mL of NH with an ammonia nitrogen concentration of 200.00mg / L 4 Cl solution was shaken at a constant temperature of 60 ° C, and samples were taken every 0.5 h to determine the concentration of ammonia nitrogen. And according to formula (1) calculate the equilibrium adsorption capacity of zeolite (q e , mg / g):

[0053] q e =V(C 0 -C e ) / m (1)

[0054] Among them: C 0 is the initial concentration of ammonia nitrogen (mg / L), C e is the remaining ammonia nitrogen concentration (mg / L) in the zeolite adsorption equilibrium solution, m is the do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com