Method for treating acid-containing heavy crude oil refining saline sewage

A heavy crude oil and treatment method technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problem of difficult sewage compliance and achieve the effect of reducing CODcr value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

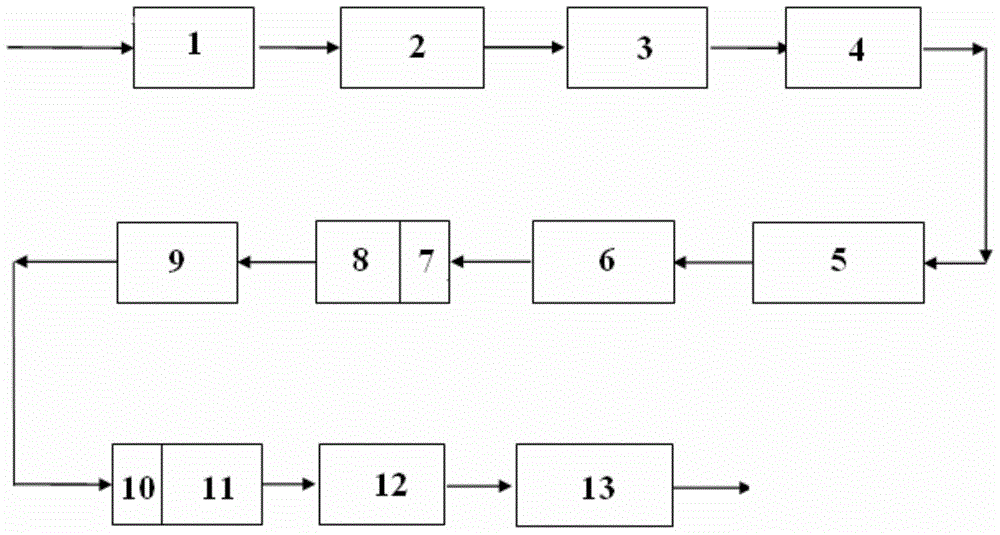

Image

Examples

preparation example Construction

[0035] In the present invention, there is no special requirement on the specific type of the heterogeneous catalyst, and various ozone catalytic oxidation catalysts commonly used in the field that can reduce the CODcr value of the water body can be used. In order to further reduce the CODcr value, the heterogeneous catalyst is preferably prepared by mixing amorphous alumina and iron oxyhydroxide powder at a ratio of 100:1 to 30 on a dry basis; through rolling granulation, curing, drying, and roasting. The finished catalyst; The preparation method of described heterogeneous catalyst comprises the following steps:

[0036] (a) uniformly mix amorphous alumina and ferric oxyhydroxide powder;

[0037] (b) Put the mixture obtained in step (a) into the tumbling granulator, spray into the binder for tumbling granulation, the binder is selected from one of water, silica sol, aluminum sol or a mixture thereof, in the form of solution or colloid In the form of atomization spraying, the ...

Embodiment 1

[0071] This example is used to illustrate the treatment method of the present invention for the treatment of salty wastewater from refinery of acid-containing heavy crude oil.

[0072] Put acid-containing heavy crude oil Penglai 19-3 crude oil refinery point source saline sewage into the homogeneous regulating tank 1, and regularly and irregularly discharged point source saline sewage are mixed in the homogeneous regulating tank 1 to achieve homogeneity , the oil content after mixing and homogenizing salty sewage is 732mg / L, CODcr is 4615mg / L, BOD 5 / COD is 0.4, suspended matter SS content is 1233mg / L, ammonia nitrogen content is 78mg / L, and total nitrogen content is 120mg / L; the homogenized saline sewage is gravity settled for 36 hours, so that slick oil, large particle SS and Separating the water body, recovering the slick oil that floats up to the top of the homogeneous regulating tank 1, removing the large particle SS that settled to the bottom of the homogeneous regulatin...

Embodiment 2

[0079] This example is used to illustrate the treatment method of the present invention for the treatment of salty wastewater from refinery of acid-containing heavy crude oil.

[0080] The point source saline sewage from the refining of acidic heavy crude oil Baslow crude oil is collectively input into the homogeneous regulating tank 1, and the regularly and irregularly discharged point source saline sewage is mixed in the homogeneous regulating tank 1 to achieve homogeneity. After the salty sewage is mixed and homogenized, the petroleum content is 943mg / L, CODcr is 5005mg / L, BOD 5 / COD is 0.42, suspended matter SS content is 1564mg / L, ammonia nitrogen content is 78mg / L, and total nitrogen content is 117mg / L; the homogenized saline sewage is gravity settled for 36 hours, so that slick oil, large particle SS and Separating the water body, recovering the slick oil that floats up to the top of the homogeneous regulating tank 1, removing the large particle SS that settled to the b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com