Ion nitrocarburizing compound layer phase adjustment and control method for SDC 99 steel

A technology of ion nitrocarburizing and compound layer, which is applied in the surface treatment of iron and steel materials and the surface nitriding treatment of iron and steel workpieces. It can solve the problems of high risk of hydrogen use, difficult process control, and difficult control of bombardment results. Achieve the effect of improving comprehensive physical and chemical properties, easy to control, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

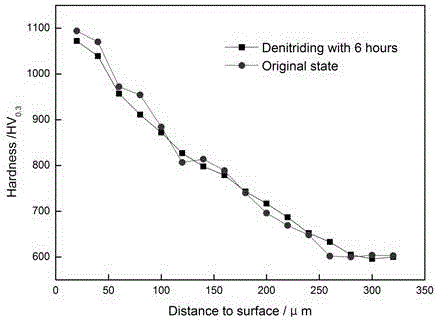

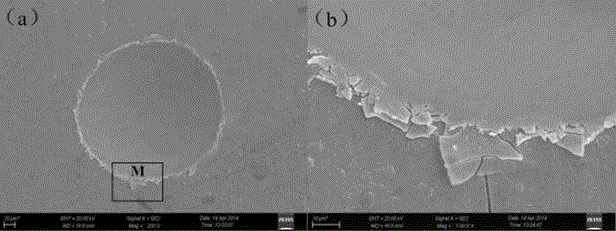

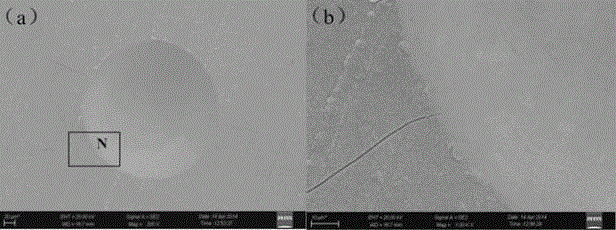

[0019] In this example, see figure 1 , an ion nitrocarburizing compound layer phase control method for SDC99 steel, setting different experimental conditions to carry out A, B, C and D group experiments, including the following steps:

[0020] a. adopt the L-DMC plasma nitriding furnace produced by Wuhan Material Protection, place the SDC99 steel workpiece to be treated on the surface in the plasma nitriding furnace, and the material composition of the SDC99 steel workpiece is calculated as: : C: 0.9-1.0%, Si: 0.4-0.6%, Mn: 0.2-0.4%, Cr: 8.5-9.0%, Mo: 1.40-1.60%, V: 0.20-0.40%, the rest is Fe, in the plasma In the nitriding furnace, use NH 3 +CO 2 Ionic nitrocarburizing process with NH 3 As nitrogen source, CO 2 As a carbon source, NH is fed into the plasma nitriding furnace 3 The flow rate is 550-620mL / min, so that the NH in the plasma nitriding furnace 3 and CO 2 The molar ratio of the two gas sources is 16:1, and the reaction temperatures of the controlled nitrocarbu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com