Method for controlling nitrogen content of nitrogen-containing non-sulfur-containing steel grades

A control method and technology for sulfur-containing steel, applied in the direction of manufacturing converters, etc., can solve the problems of not meeting the requirements of N content, resource consumption process, low sulfur content, etc., to improve the nitrogen fixation effect, reduce the denitrification rate, and control the nitrogen content. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

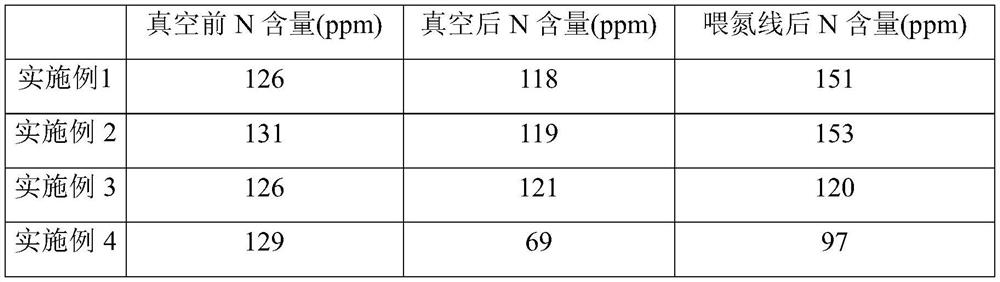

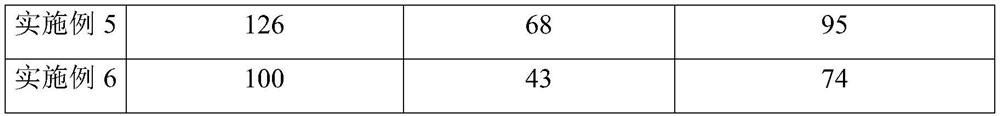

Examples

Embodiment 1

[0014] The steel grade produced is SG02

[0015] (1) Preparation before production: purge the equipment and pipelines to ensure that they are unimpeded; turn on the N 2 Pipeline valve, then cut off the Ar pipeline valve, adjust the gas flow rate to 800NL / min, and continue to spray at this flow rate for 15 minutes; check the pipeline airtightness under normal working pressure and flow rate, and the stability of pressure, flow rate and equipment operation property; check whether N 2 -Ar switching and flow regulation control, guaranteed at N 2 When the gas circuit fails, it can switch to Ar for normal gas supply;

[0016] (2) Converter smelting: N 2 As the bottom blowing gas, the flow rate is adjusted to 600NL / min;

[0017] (3) LF furnace treatment: according to the S composition, the sulfur line is supplemented before hanging the bag, and the S content is 0.0041% at the end of smelting, and the sulfur line is fed for 50 meters, and the S content is 0.0096% when the RH furnac...

Embodiment 2

[0020] The steel grade produced is SG01

[0021] (1) Preparation before production: purge the equipment and pipelines to ensure that they are unimpeded; turn on the N 2 Pipeline valve, then cut off the Ar pipeline valve, adjust the gas flow rate to 800NL / min, and continue to spray at this flow rate for 15 minutes; check the pipeline airtightness under normal working pressure and flow rate, and the stability of pressure, flow rate and equipment operation property; check whether N 2 -Ar switching and flow regulation control, guaranteed at N 2 When the gas circuit fails, it can switch to Ar for normal gas supply;

[0022] (2) Converter smelting: N 2 As the bottom blowing gas, the flow rate is adjusted to 600NL / min;

[0023] (3) LF furnace treatment: According to the S composition, the sulfur line is supplemented before lifting the bag. The S content is 0.0048% at the end of smelting, and the sulfur line is fed for 50 meters. When the RH furnace arrives at the station, the S c...

Embodiment 3

[0026] The steel grade produced is SG04

[0027] (1) Preparation before production: purge the equipment and pipelines to ensure that they are unimpeded; turn on the N 2 Pipeline valve, then cut off the Ar pipeline valve, adjust the gas flow rate to 600NL / min, and continue to spray at this flow rate for 20 minutes; check the air tightness of the pipeline under normal working pressure and flow rate, and the stability of pressure, flow rate and equipment operation property; check whether N 2 -Ar switching and flow regulation control, guaranteed at N 2 When the gas circuit fails, it can switch to Ar for normal gas supply;

[0028] (2) Converter smelting: N 2 As the bottom blowing gas, the flow rate is adjusted to 600NL / min;

[0029] (3) LF furnace treatment: according to the S composition, the sulfur line is supplemented before hanging the bag, and the S content is 0.0043% at the end of smelting, and the sulfur line is fed for 50 meters, and the S content is 0.0098% when the R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com