Interactive type three-chamber biological fuel cell device and method for denitriding wastewater by using device

A biofuel cell, interactive technology, applied in biochemical fuel cells, biological water/sewage treatment, chemical instruments and methods, etc., can solve the doubts about the application prospect of denitrification microbial fuel cells, the low rate of denitrification, and the power generation of batteries. problems such as low capacity, to achieve good environmental and economic benefits, low sludge production, and improved sewage treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

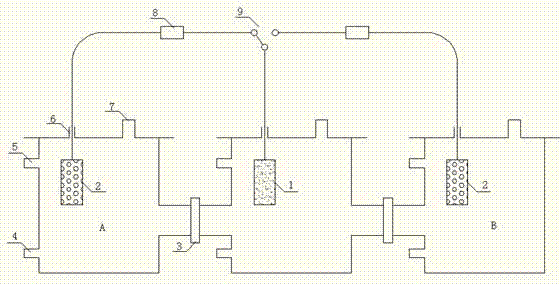

[0034] The above-mentioned interactive three-chamber biofuel cell device was used to carry out the denitrification experiment of wastewater containing nitrate nitrogen.

[0035] Step 1: Inoculate the anode chamber (1) with anaerobic sludge, add NaAc (COD: 1000 mg / L) into the anode solution as an electron donor, and inoculate the two cathode chambers (2) with anoxic denitrification sludge, and the cathode enters Water (simulated wastewater) contains sodium acetate (200 mg / L COD) and NaNO 3 (NO 3 –N is 70 mg / L), add 2g / L of Na in addition 2 CO 3 As an inorganic carbon source required for the growth of cathode denitrifying bacteria;

[0036] Step 2: Catholyte sequentially enters the cathode chambers (A, B) on both sides of the three-chamber biofuel cell alternately in batches. First, the cathode on side A is disconnected from the anode, and the cathode chamber on side A is filled with water to carry out the non-organic carbon source. Electrode denitrification;

[0037] Step...

( example 1)

[0047] A traditional double-chamber denitrification biofuel cell is used, and other experimental conditions are the same as in Example 1, but the negative and positive electrodes are always connected, as a comparison with Case 1. After 48 hours of reaction, the cathode effluent NO 3 -N 28.7mg / L, at this time COD 22.4 mg / L, at this time, the average voltage within 48h is 203.1mV, and the average output power is 18.4mW / cm 2 . The comprehensive denitrification rate is 2.46 mg / (Lh), and the organic carbon source COD / NO consumed by denitrification 3 - The ratio is 4.3, generating 4.46W of electrical energy. Various performance indicators such as organic carbon source consumption are lower than the device of the present invention (case 1), and the amount of treated water is also reduced by half.

[0048]

Embodiment example 3

[0050] Other operating conditions are the same as in Example 1, and no interactive control switch is used for the three-chamber battery, so that the two batteries are opened and closed at the same time, compared with Example 1. There are two processes:

[0051] (1) The non-electrode denitrification process is carried out at the same time on the A and B sides: disconnect the anode and the two cathodes, and after 24 hours of reaction, the cathode NO 3 -N 35.5 mg / L, COD 31.2 mg / L, the denitrification rate of this process is 4.11 mg / (Lh) (the result is the same as the process 1 in the implementation case 1), at this time, the batteries A and B do not produce electricity.

[0052] (2) The electrode denitrification process is carried out at the same time on the A and B sides: the anode and the two cathodes are connected, and after 24 hours of continuous reaction, the single-side cathode NO 3 -N 32.9 mg / L, COD 30.4 mg / L, the denitrification rate of this process is 0.15 mg / (Lh), at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com