Dynamic and static pressure bearing circular tooth gear oil pump

A circular arc gear, dynamic and static pressure technology, applied in the direction of pumps, rotary piston type/swing piston type pump components, lubrication pumps, etc., can solve the problems of large axial and radial unbalanced force, large leakage, oil trapped in the oil pump, etc. Achieve the effect of solving low-speed wear, long service life and reducing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

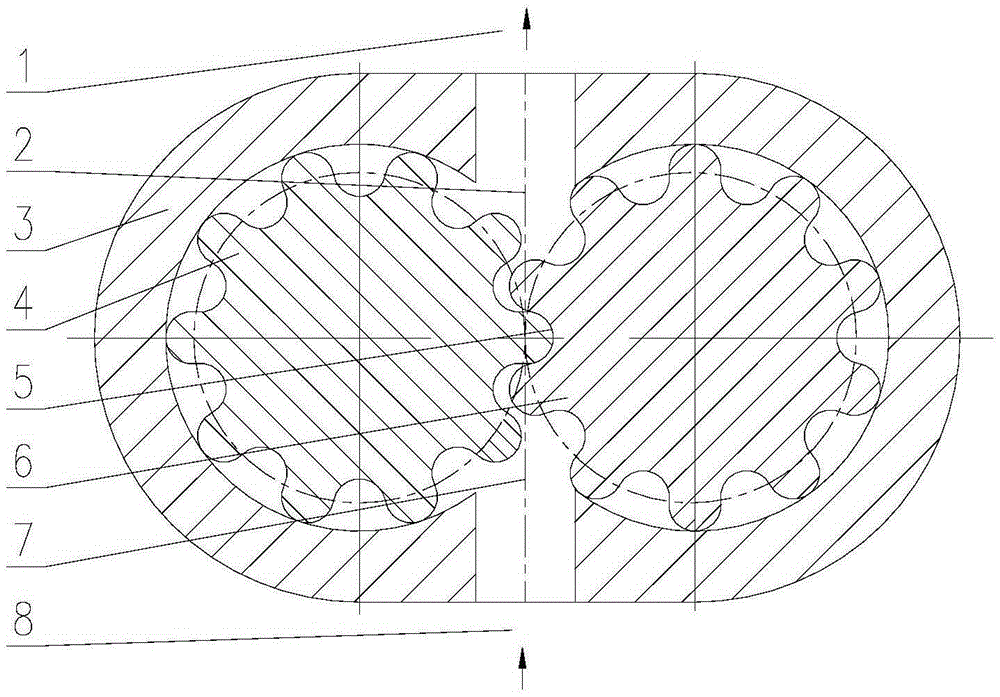

[0020] The arc gear pump is a rotary pump that relies on the change and movement of the working volume formed between the pump cylinder and the meshing gear to deliver liquid or pressurize it. When the gear of the arc gear pump rotates, the volume of the space on the side where the gear is disengaged becomes larger, forming a vacuum to suck the liquid, and the volume of the space on the meshing side of the gear changes from large to small, and the liquid is squeezed into the pipeline. The suction chamber and the discharge chamber are separated by the meshing line of two arc gears. The resistance at the outlet of the gear oil pump forms the delivery pressure of the oil pump.

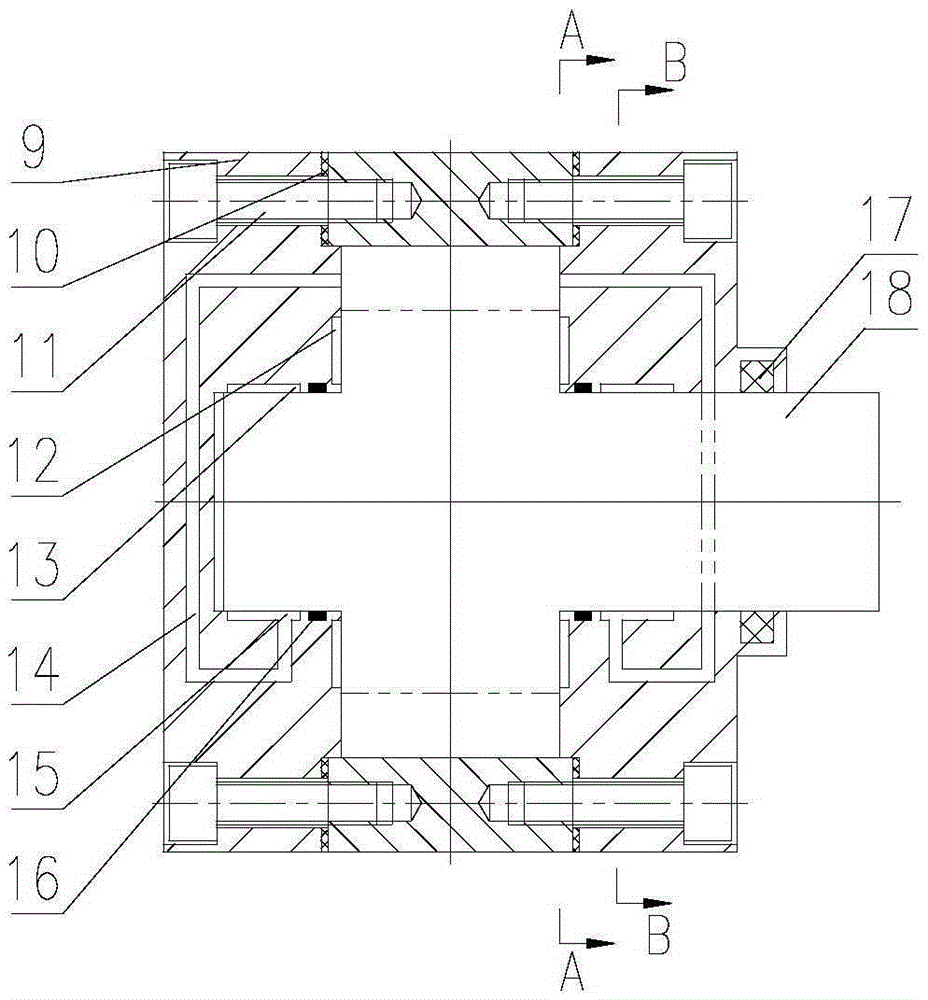

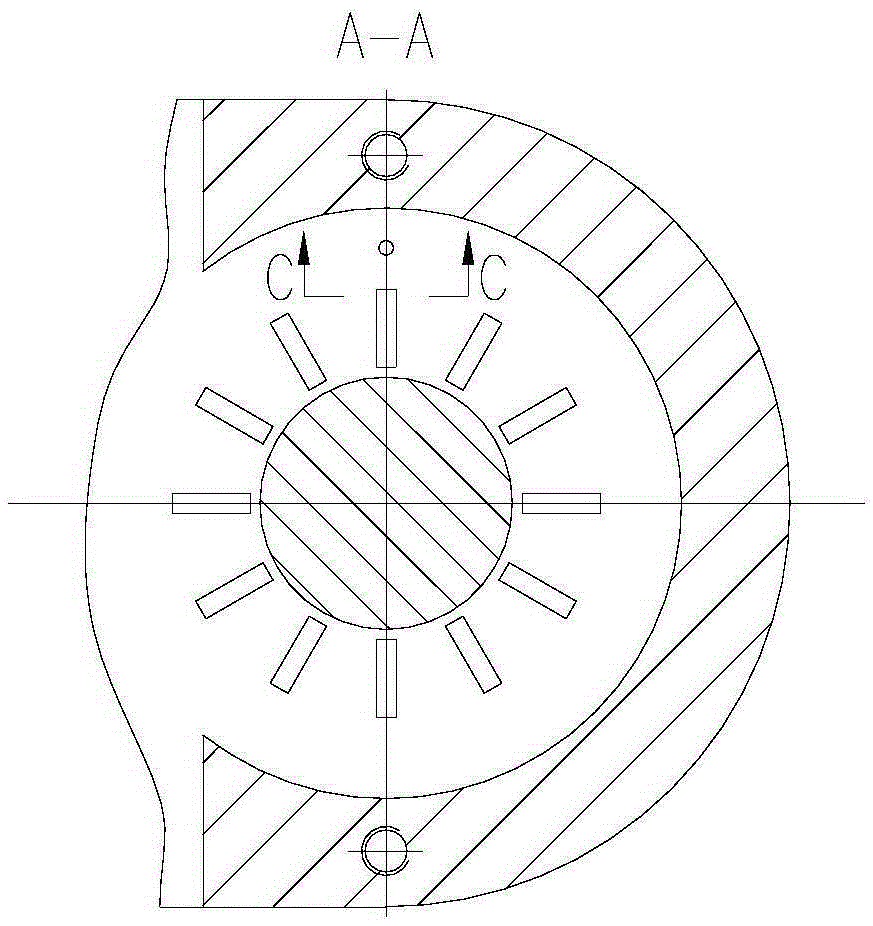

[0021] See Figure 1 to Figure 3 The gear oil pump of the present invention includes a pump body 3 with an active arc gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com