Fully mechanized mining face centralized control room

A fully-mechanized mining face and room body technology, applied in industrial buildings, door/window accessories, buildings, etc., can solve problems such as no unified connection method and placement channel for cables, affecting underground safety production, leakage or short circuit, etc., to achieve Protection from misconnection and damage, convenient daily maintenance, and orderly installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

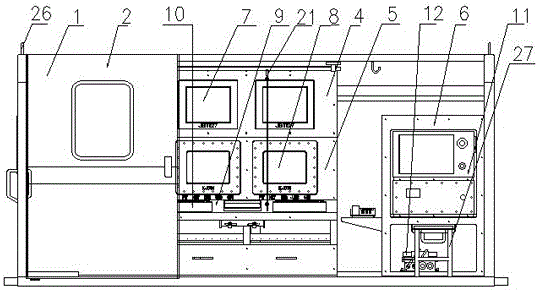

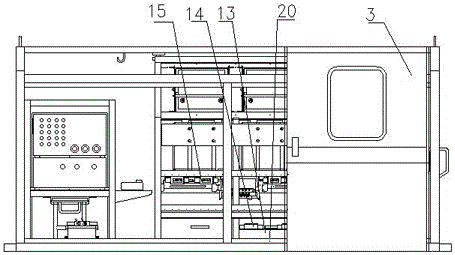

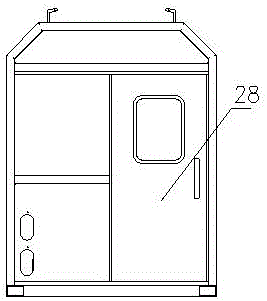

[0019] Such as figure 1 As shown, a centralized control room for fully mechanized mining working face, which includes a frame-type room body 1, front and rear sliding doors 2 and rear sliding doors 3 are respectively arranged on the front and rear sides of the room body 1, and upper mounting brackets 4, The lower mounting bracket 5 and the supporting frame 6, the upper mounting bracket 4 are fixedly connected to the top of the room, and three explosion-proof monitors 7 are embedded in it, the lower mounting bracket 5 is connected to the upper mounting bracket 4, and three explosion-proof computers are embedded in it 8, wherein the lower mounting bracket 5 is also provided with an operation panel 9, the operation panel 9 is provided with a sunken groove, and the explosion-proof keyboard 10 is embedded in the sunken groove; the upper part of the support frame 6 is embedded with a main controller 11, and the lower part An explosion-proof power supply 12 is installed; wherein the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com