Recovering system of expandable polystyrene

A technology of expandable polystyrene and recycling system, which is applied in the direction of plastic recycling, recycling technology, separating solids from solids with airflow, etc. It can solve problems such as simple structure, broken raw material structure, and difficult processing and molding. Achieve uniform feeding, protect equipment safety, and achieve good crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] As shown in Figure 15, this system is by pulverizer 26, raw material bin 4 ', screening dedusting machine 27 and powder bin 5 '.

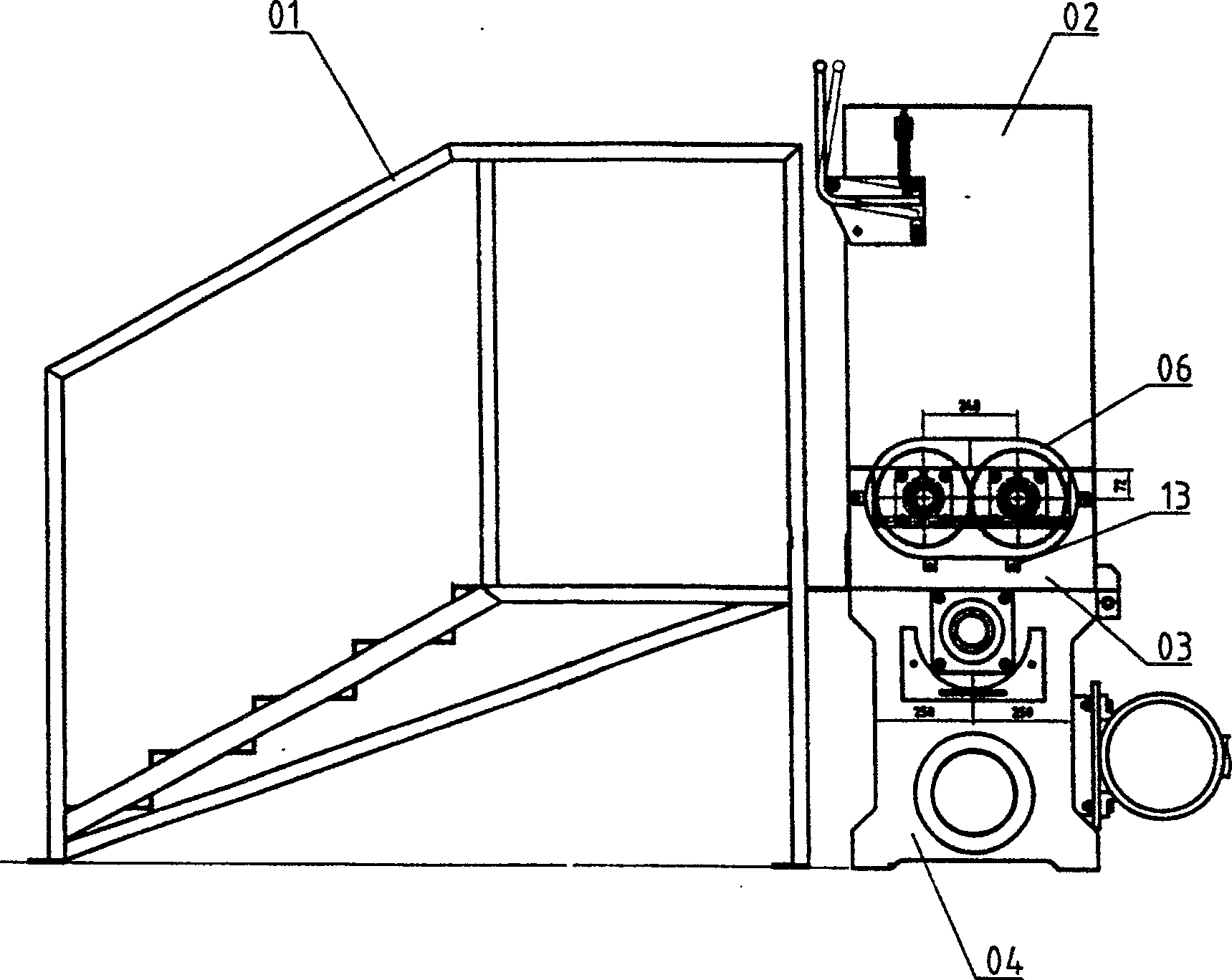

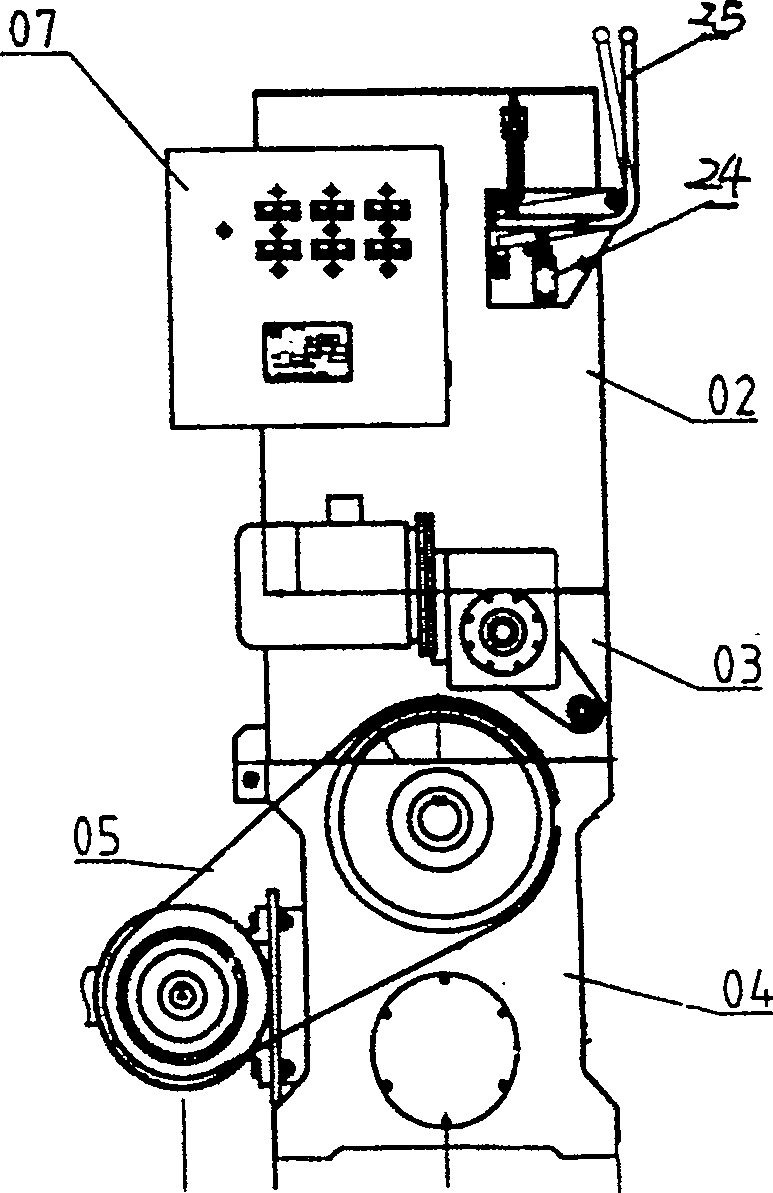

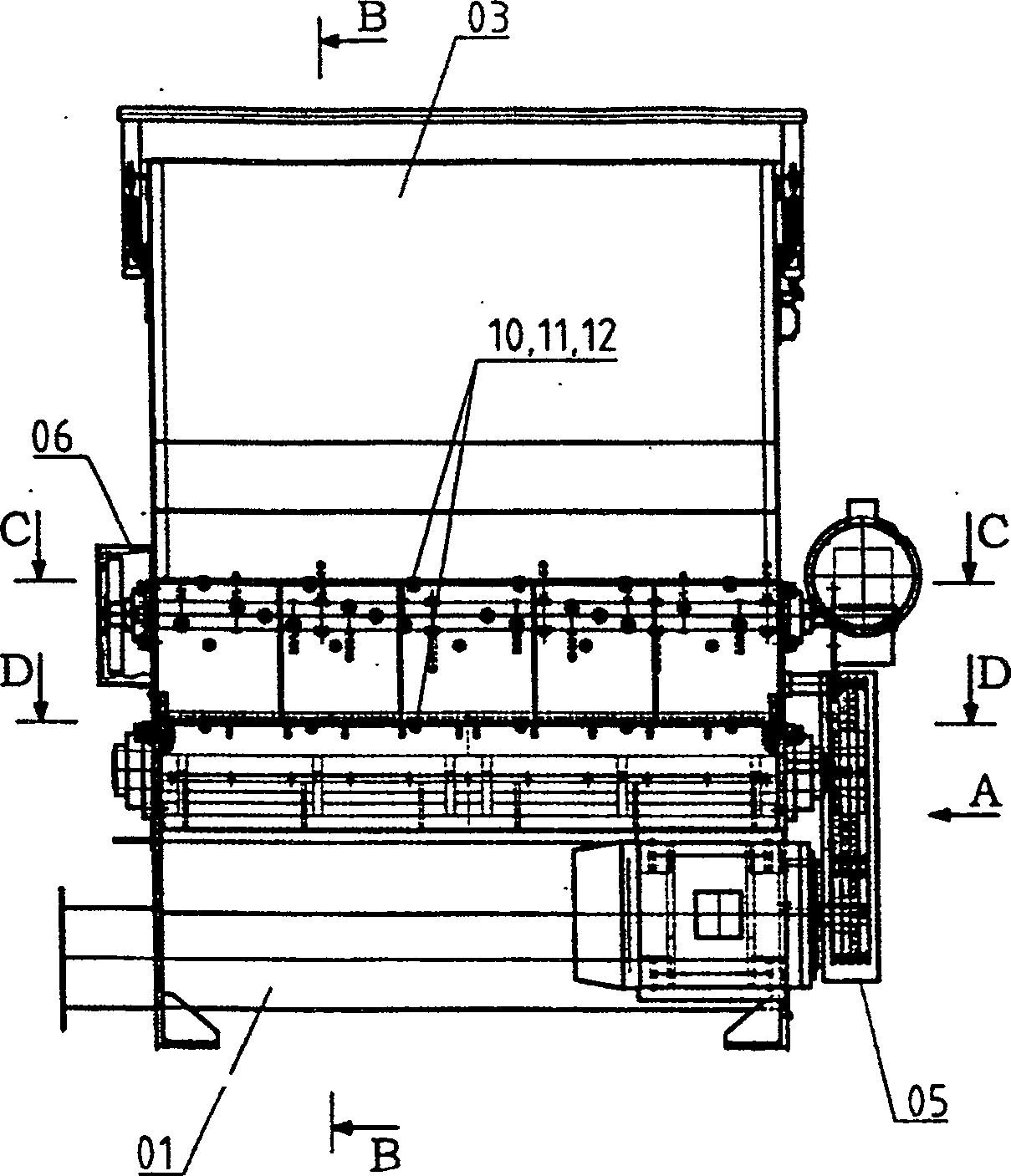

[0026] Such as figure 1 , figure 2 , image 3 , Figure 5 As shown, the pulverizer includes a workbench 1, a feed hopper 2, a belt pulley 5, a transmission gear 6 and a control box 7. The pulverizer is provided with a feed hopper 2 in turn, and a crushing mechanism 3 is provided under the feed hopper. A grinding mechanism 4 is arranged under the mechanism; a belt cover and a gear cover are respectively arranged on the belt disc 5 and the transmission gear 6 .

[0027] Such as Figure 6 , The pulverizing mechanism is made up of the active pulverizing shaft 8 distributed in parallel, the driven pulverizing shaft 9, and the pulverizing knives 14 arranged on the shaft, and the pulverizing knives are arranged on the shaft according to a 45° helical distribution. Such as Figure 4 , Figure 7 , Figure 8 , the grinding mechanism is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com