Fire extinguishing system for kiln operation

A fire protection system and kiln technology, applied in the field of kilns, can solve the problems of difficult workers, enlarged fire conditions, loss of personnel and equipment, etc., and achieve the effect of protecting the safety of personnel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the purpose, technical solutions and advantages of the embodiments of the present disclosure clearer, the technical solutions of the embodiments of the present disclosure will be clearly and completely described below in conjunction with the accompanying drawings of the embodiments of the present disclosure. In order to maintain the following description of the embodiments of the present disclosure For clarity and conciseness, the present disclosure omits detailed descriptions of known functions and known components to avoid unnecessarily obscuring the concepts of the present invention.

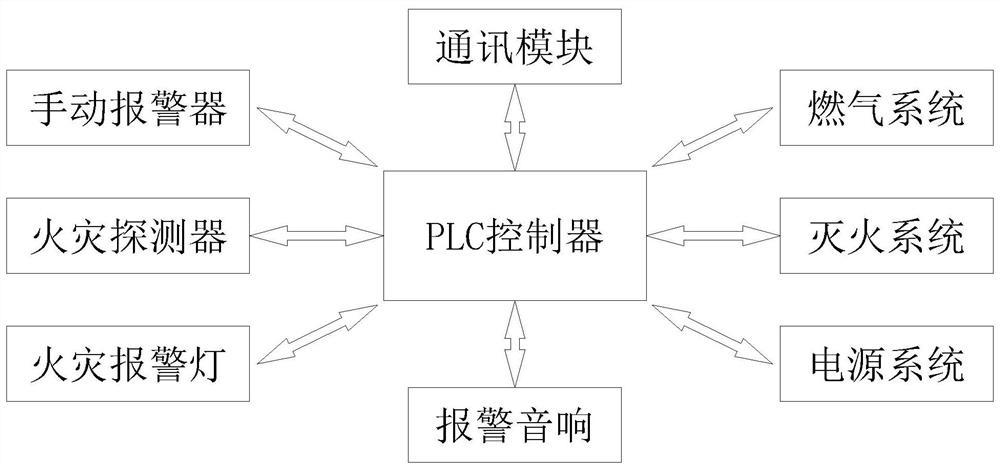

[0023] see figure 1 , a fire fighting system for kiln operation, including a PLC controller, a manual alarm, a fire detector, a fire alarm light, an alarm sound, a communication module, a gas system, a fire extinguishing system and a power supply system;

[0024] The manual alarm is electrically connected to the PLC controller, and when the staff detects that a fire oc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com