Prefabricated groove type cable comprehensive pipe rack

A comprehensive pipe gallery and cable-type technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of long construction period, achieve the effects of beautifying the urban environment, fast construction, and reducing traffic impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The features of the present invention and other related features will be further described in detail below with examples in conjunction with the accompanying drawings, so as to facilitate the understanding of those skilled in the art.

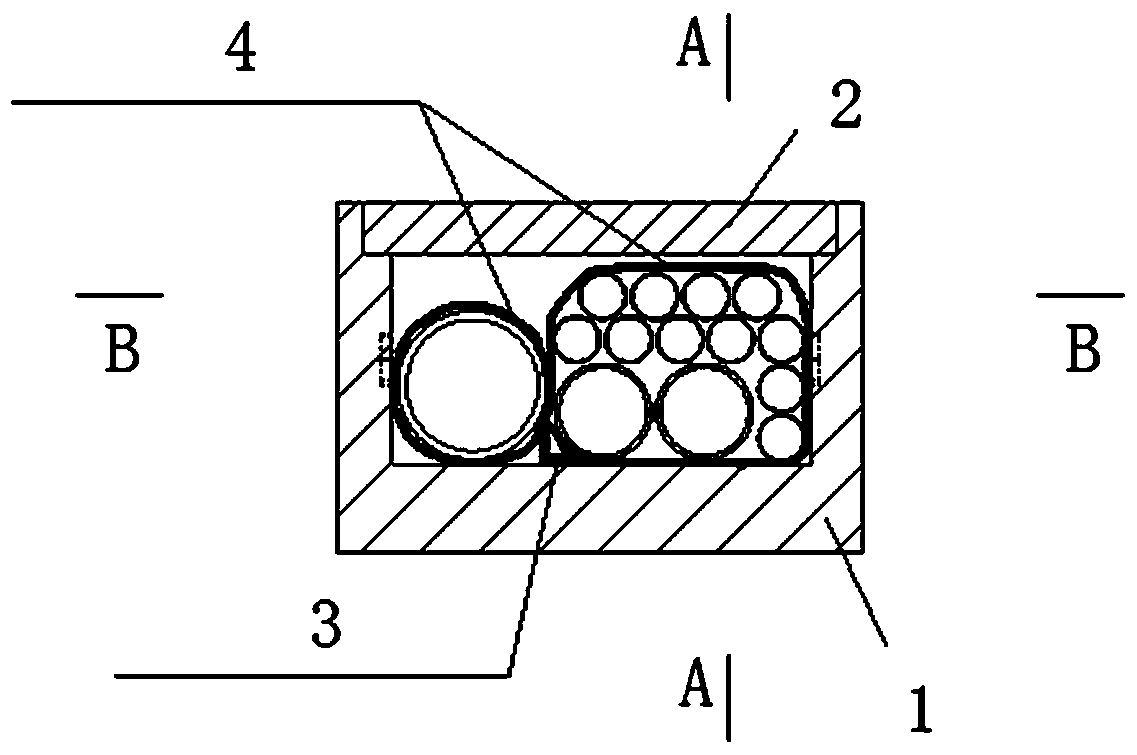

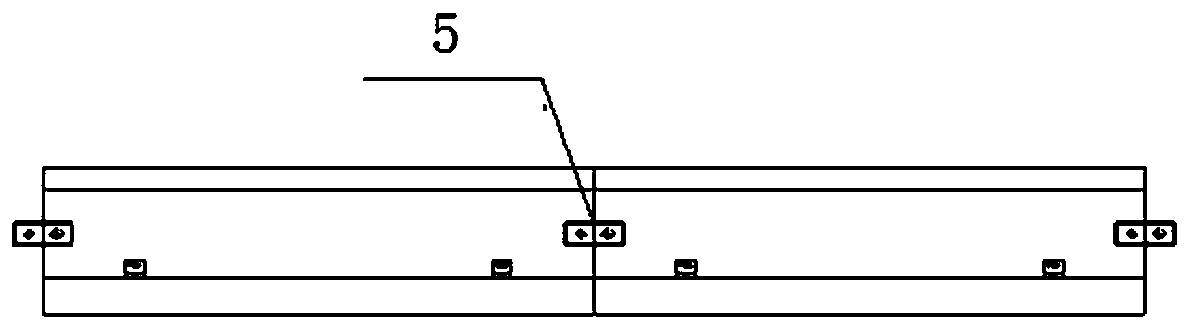

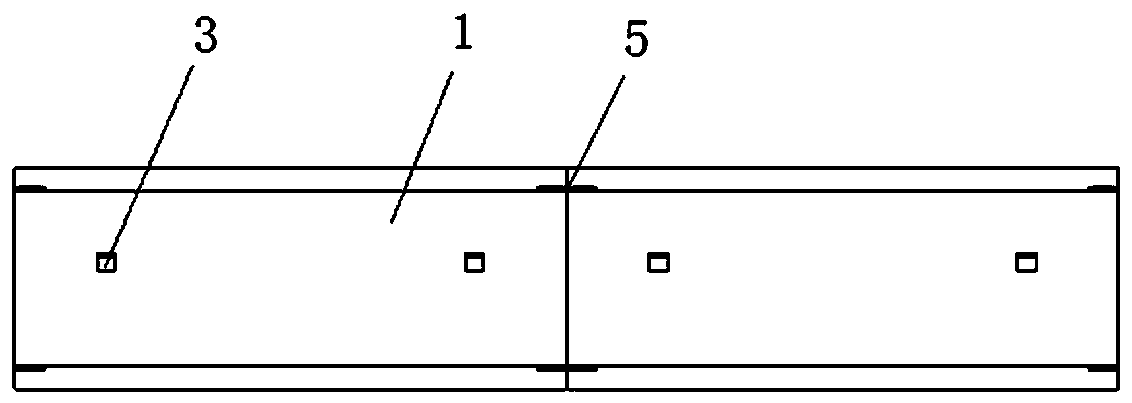

[0028] The present invention is a prefabricated and assembled cable-type comprehensive pipe gallery for rapid construction, which is formed by splicing several sections of prefabricated grooves, and mainly includes U-shaped groove 1, cover plate 2, internal casing and ferrule 4, and fixing sleeve The hoop angle steel 3 and the fixed pipe joint steel plate 5 are characterized in that: the U-shaped groove 1 is constructed by prefabricated assembly, and the inner casing is directly laid inside the groove, and arranged in a certain order according to the diameter of the casing. Among them, the 150mm casing is arranged on one side of the U-shaped groove bottom plate, and the 50mm and 100mm casings are stacked on the other side of the U-shaped ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com