Heat dissipation system of underground box type transformer

A technology of box-type transformer and heat dissipation system, which is applied in the direction of transformer/inductor cooling, substation/switchgear cooling/ventilation, etc., which can solve the difficulty of adapting to the trend of miniaturization of transformer pit boxes and meet the heat dissipation requirements of transformers , the small external space of the transformer, etc., to achieve effective heat dissipation, safe and durable use, and high heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

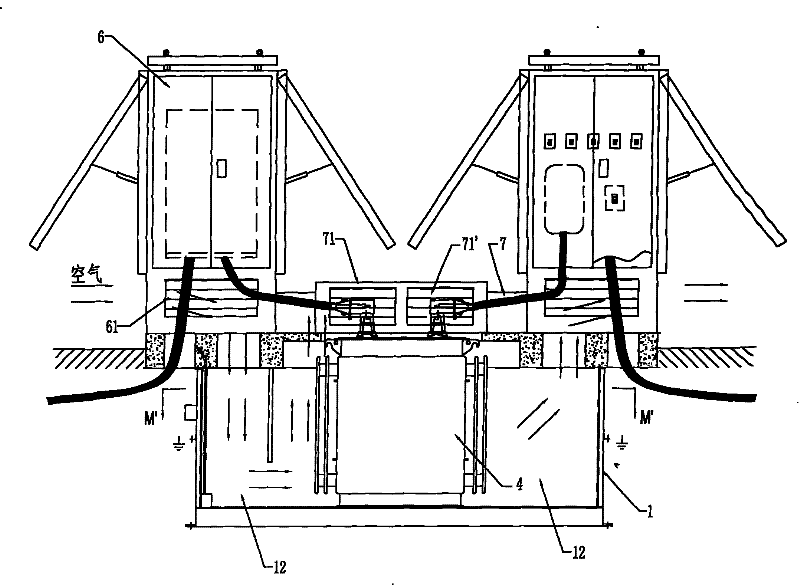

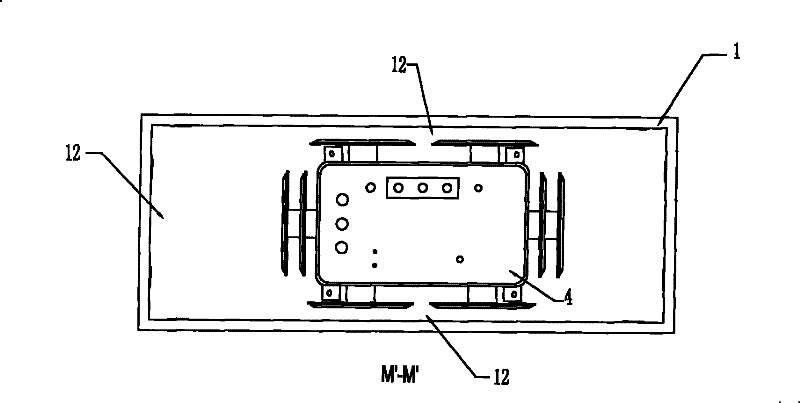

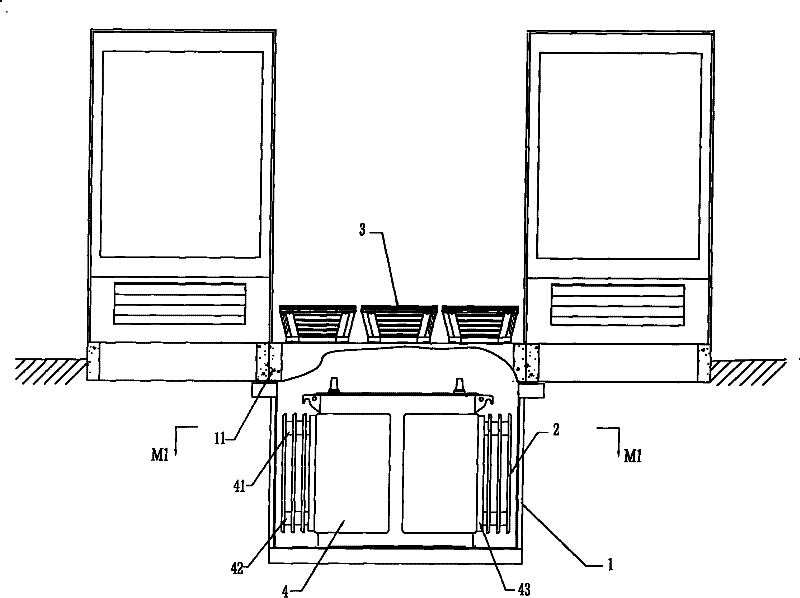

[0039] Figure 3 ~ Figure 4 The heat dissipation system of an underground box-type transformer shown is Embodiment 1 of the present invention, which includes a natural convection heat dissipation mechanism and an enhanced heat exchange mechanism, wherein the structure of the natural convection heat dissipation mechanism is: the oil-immersed transformer body 4 is arranged on There is a cavity 12 in the prefabricated pit box 1 and between the inner wall of the pit box 1. The cavity 12 is used as a ventilation channel and a vent on the ground to form a natural convection heat dissipation system. The vent includes The ventilation hood 3 provided on the pit cover 11 and the ventilation opening 61 through which the power distribution cabinet 6 communicates with the outside world (ie air). The enhanced heat exchange mechanism is composed of a heat sink and a connecting piece connecting the heat sink to the outer wall of the oil-immersed transformer body 4. In this embodiment, two rei...

Embodiment 2

[0043] Figure 5 ~ Figure 8 The radiating system of a kind of underground box-type transformer shown is the embodiment 2 of the present invention, and it is different from embodiment 1 in that: each enhanced heat exchange mechanism outermost radiator and pit box 1 inner wall leave There is a gap; and between the four enhanced heat exchange mechanisms installed in the two long directions of the transformer body 4 and the inner wall of the pit box 1, there are metal heat transfer parts. The metal heat transfer parts are composed of a pair of elastic parts with good thermal conductivity. It consists of a hollow triangular wedge 51 with right-angled sides made of material. The hypotenuses of a pair of right-angled wedges 51 are opposite and in contact, and the parallel right-angled sides are respectively in contact with the heat sink 2 and the inner wall of the pit box 1 and are clamped between the outermost heat sink and the inner wall of the pit box 1, so as to Conduct the heat...

Embodiment 3

[0046] Figure 9 ~ Figure 11 The heat dissipation system of a kind of underground box-type transformer shown is embodiment 3 of the present invention, and it is different from embodiment 1 in that: the enhanced heat exchange mechanism installed in the two short directions of transformer body 4 is equipped with oil inlet pipe and oil outlet pipe Two heat sinks, and there is a gap between the outermost heat sink and the inner wall of the pit box 1; the enhanced heat exchange mechanism installed in the two long directions of the transformer body 4 is provided with a heat dissipation plate that is in contact with the inner wall of the pit box sheet, and the connector used for connection is an elastic corrugated heat transfer tube 52, the corrugated heat transfer tube is arranged between the transformer body and the heat sink, and its two ends are connected with the transformer and the heat sink respectively, and the corrugated heat transfer tube is connected to the pit The inner w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com