Composite heat dissipation film and preparation method thereof

A heat dissipation film and composite technology, applied in the direction of adhesive type, conductive adhesive, adhesive additive, etc., can solve the problems of poor heat dissipation of heat dissipation film, insufficient shielding function, poor heat dissipation effect, etc., and achieve convenient processing performance, film layer is thin, uniform and dense, and overcomes the effect of insufficient heat transfer and shielding functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

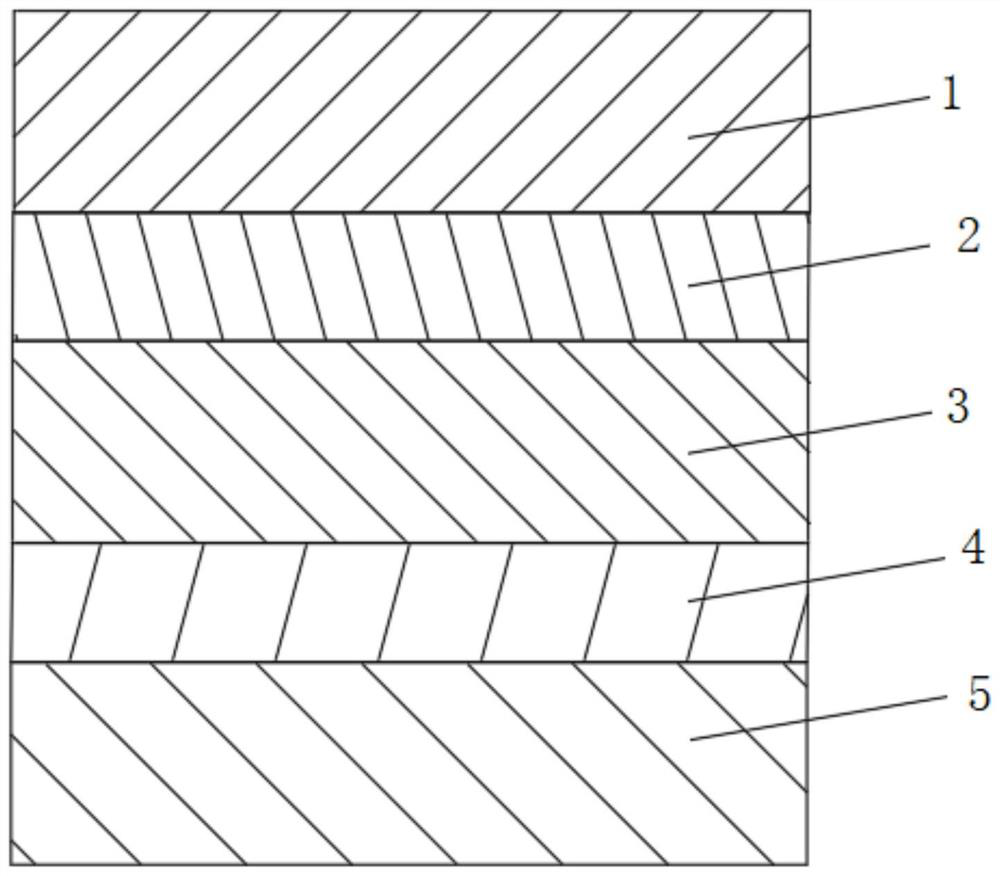

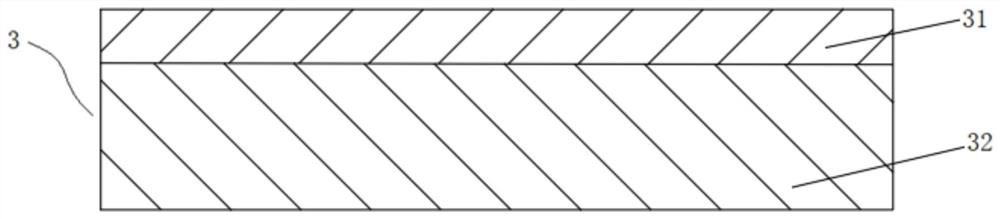

[0139] Such as figure 1 , 2 As shown, the composite heat-fixing film having a 3D structural metal layer of the present invention includes a sequential thermally conductive layer 1, a thermally conductive attachment layer 2, 3D structural metal layer 3, a thermally conductive adhesive layer 4, a protective film layer 5, wherein the 3D structural metal The layer is composed of the base metal layer 31, the thick metal layer 32 is closely over.

[0140] 1, prepare the heat transfer layer

[0141] The graphene sheet having a thickness of 17 μm and a width of 140 mm is selected as the thermally conductive layer.

[0142] 2. Preparation of heat transfer layer

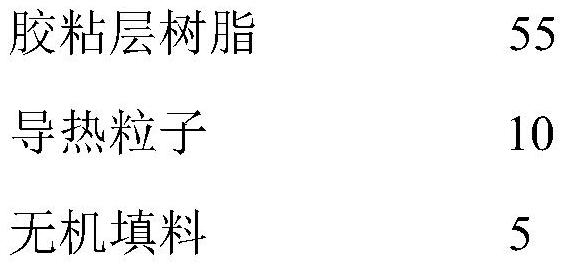

[0143] 2A) formulated by slurry

[0144] The heat-receiving paste is applied to the surface of the heat conductive layer, and then dry, the heat conductive receiving layer having a surface unevenness is formed, and has a three-dimensional surface structure (3D structure); the layer thickness is 5-20 μm, wherein the layer thickness...

Embodiment 1A

[0188] In addition to step 4), a conductive particle is also contained in the conductive plasma, and the weight ratio of the conductive particles is 15, the conductive particles are copper powder, and the average particle size of the copper powder is 10 μm, and the remaining is the same as in Example 1.

[0189] In a particular embodiment of the invention, the conductive particles will be described as an example of copper powder, and other conductive particles are nickel, copper, silver (powder), is suitable for use in the present invention.

[0190] The heat dissipation and shielding effect of the prepared composite heat dissipation film are shown in Table 1, 2.

Embodiment 2

[0192] Such as figure 1 As shown, the heat dissipation shield film having a 3D structural metal layer of the present invention includes a thermally conductive layer 1, a thermally conductive adhesive layer 3, a protective film layer 4, a thermally conductive adhesive layer 3, and a protective film layer 4.

[0193] 1, prepare the heat transfer layer

[0194] As in step 1 of Embodiment 1).

[0195] 2, prepare 3D structural metal layer

[0196] The manufacturing method of the 3D structural metal layer can be prepared as follows: The film layer of an irregular stereo surface structure or a microporous structure is formed on the surface of the existing metal foil.

[0197] A copper foil having a thickness of 18 μm (typically 12-100 μm) is used for etching, wherein the etching pressure is 2-6 kg / cm. 2 The etching treatment temperature is 30-60 ° C; the etching liquid is a copper chloride etching liquid, which has a thickness of 18 μm surface uneven, a 3D structural metal layer having...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com