A support structure of latitude and longitude foundation pit

A foundation pit support, warp and weft technology, applied in infrastructure engineering, excavation, construction, etc., can solve the problems of ineffective use of lateral stiffness, unfavorable stability of foundation pit, waste of support structure resistance, etc., and achieve wide application The effect of market and development prospects, improvement of integrity and stability, and saving of underground space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments thereof. The schematic embodiments and descriptions of the present invention are used to explain the present invention, but not as a limitation to the present invention.

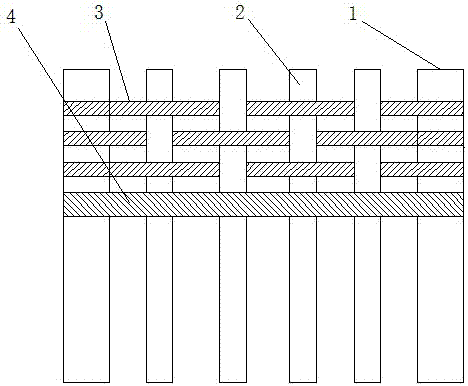

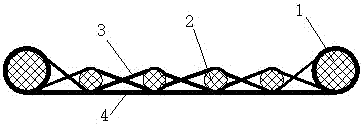

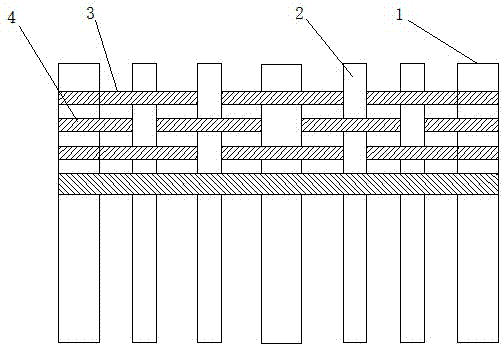

[0025] Such as figure 1 , figure 2 As shown, a latitude and longitude foundation pit support structure of this embodiment includes several rows of piles arranged in the foundation pit. The piles are composed of main piles 1 and auxiliary piles 2. In this embodiment, two main piles are set 1. The auxiliary piles 2 are distributed between the two main piles 1. The outer walls of the auxiliary piles 2 and the main piles 1 are arranged on the same plane. Both the main piles 1 and the auxiliary piles 2 are cylindrical, and the diameter and stiffness of the main pile 1 are equal. It is larger than the auxiliary pile 2, and also includes the main cable 4 and the auxiliary cable 3. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com