Overhaul device for top beam of hydraulic support with large mining height and application thereof

A technology of hydraulic support and maintenance device, which is applied to mine roof support, mining equipment, earthwork drilling and other directions, can solve problems such as affecting the efficiency of maintenance operations, affecting mining operations, and troublesome maintenance operations, saving underground space, and achieving remarkable results. The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

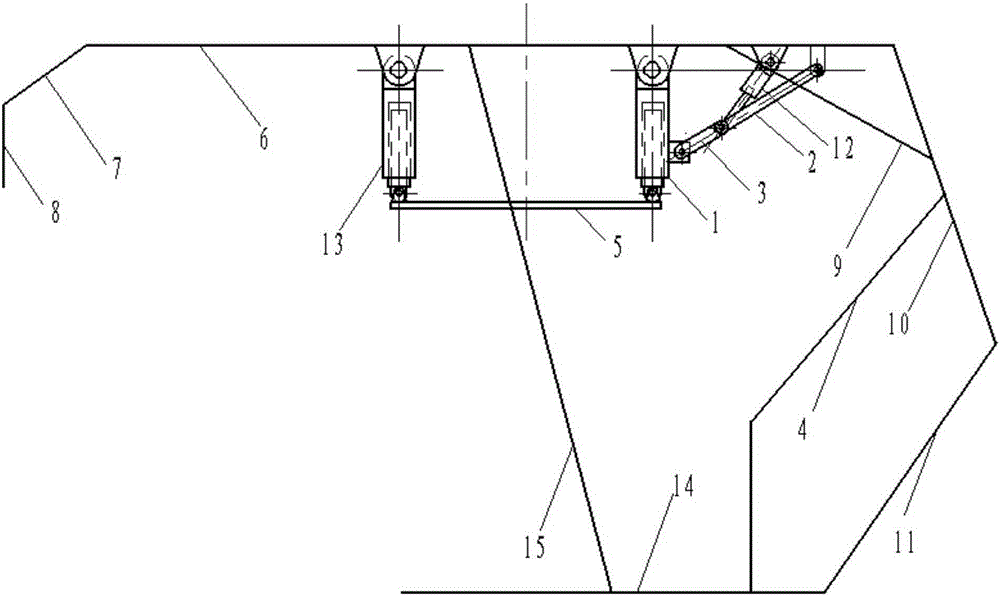

[0033] Such as figure 1 As shown, this embodiment provides a maintenance device for the top beam of hydraulic supports with large mining heights, including a double telescopic lifting jack A1 and a double telescopic lifting jack B13, a maintenance platform 5, a driving rod 3, a guide link 2 and a single telescopic lifting jack. Driving jack 12, one end of lifting jack A1 and lifting jack B13 are hinged on hydraulic support top beam 6, the other end is hinged with maintenance platform 5, one end of driving rod 3 is hinged with lifting jack B13, and the other end is hinged with guide rod 2 and drive Jack 12, one end of the driving jack 12 is hinged on the hydraulic support top beam 6, and one end of the guide link 2 is hinged on the hydraulic support top beam 6, wherein the hinge point of the guide link 2 and the top beam ear seat and the lifting jack ( Including lifting jack A1 and lifting jack B13) and the hinge point of the top beam ear seat are at the same level, and the ins...

Embodiment 2

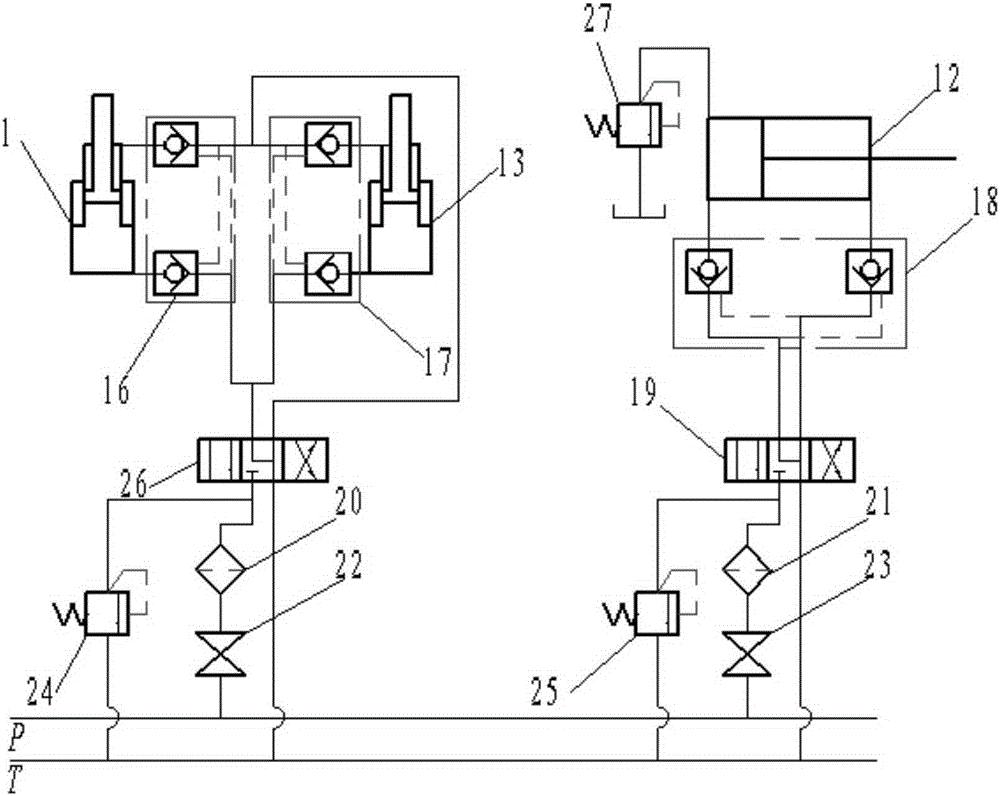

[0042] Such as figure 2 As shown, this embodiment provides an overhaul device for the top beam of hydraulic supports with large mining heights. , the hydraulic system includes a driving jack hydraulic drive system, a lifting jack hydraulic drive system and an emulsion pumping station, which provides power for the working face emulsion pumping station. The driving jack hydraulic drive system includes a hydraulic lock 18, a three-position four-way reversing valve 19, a filter 21, a stop valve 23, a safety valve 25, a first oil circuit and a second oil circuit, and the driving jack 12 passes through the hydraulic lock 18 It is connected with the three-position four-way reversing valve 19, and the three-position four-way reversing valve 19 is connected to the filter 21 and the stop valve 23 through the first oil circuit, and then connected to the oil inlet pipeline P of the emulsion pump station, and the three-position four-way reversing The valve 19 is also connected to the oil...

Embodiment 3

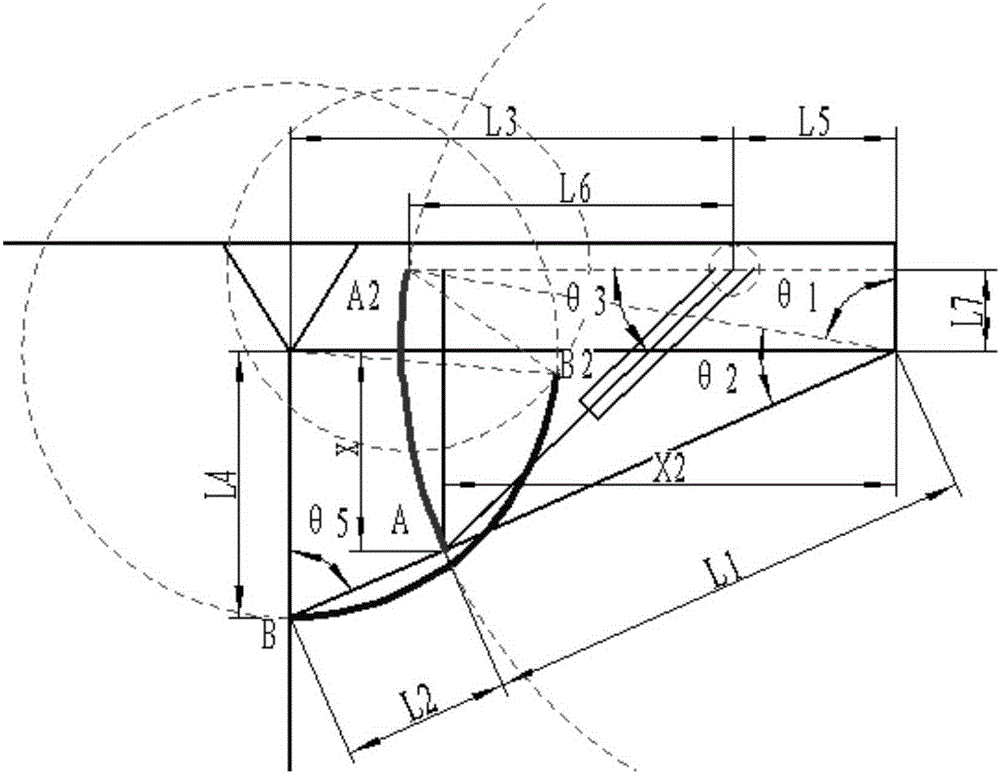

[0051] Such as image 3 As shown, this embodiment provides a working method for the overhaul device for the top beam of the large mining height hydraulic support as described in Embodiment 2, including the following steps,

[0052] (1) The driving jack 12 is supplied with oil to start, the piston rod of the driving jack 12 stretches out, and the hinge point of the driving jack 12 and the driving rod 3 is constrained by the guide connecting rod 2 to perform circular rotation (by image 3 Point A2 in the movement to point A), the hinge point of the driving rod 3 and the lifting jack B13 rotates in a circle around the hinge point of the lifting jack B13 and the hydraulic support top beam 6 (by image 3 Point B2 in the middle moves to point B), promote lifting jacks 1, 13 and inspection platform 5 to rotate to the vertical locked state;

[0053] (2) After the step (1) is completed, the lifting jacks 1 and 13 are started to supply oil, and the piston rods of the lifting jacks 1 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com