Method for detecting and monitoring grouting material by utilizing conductivity difference

A technology of grouting materials and electrical conductivity, applied in the field of grouting materials, can solve problems such as the inability to grasp the grouting situation, the number of drills, the limited location, and the impact on the final grouting quality, so as to achieve high practical value and promotion value, and improve resource utilization. , The effect of low construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

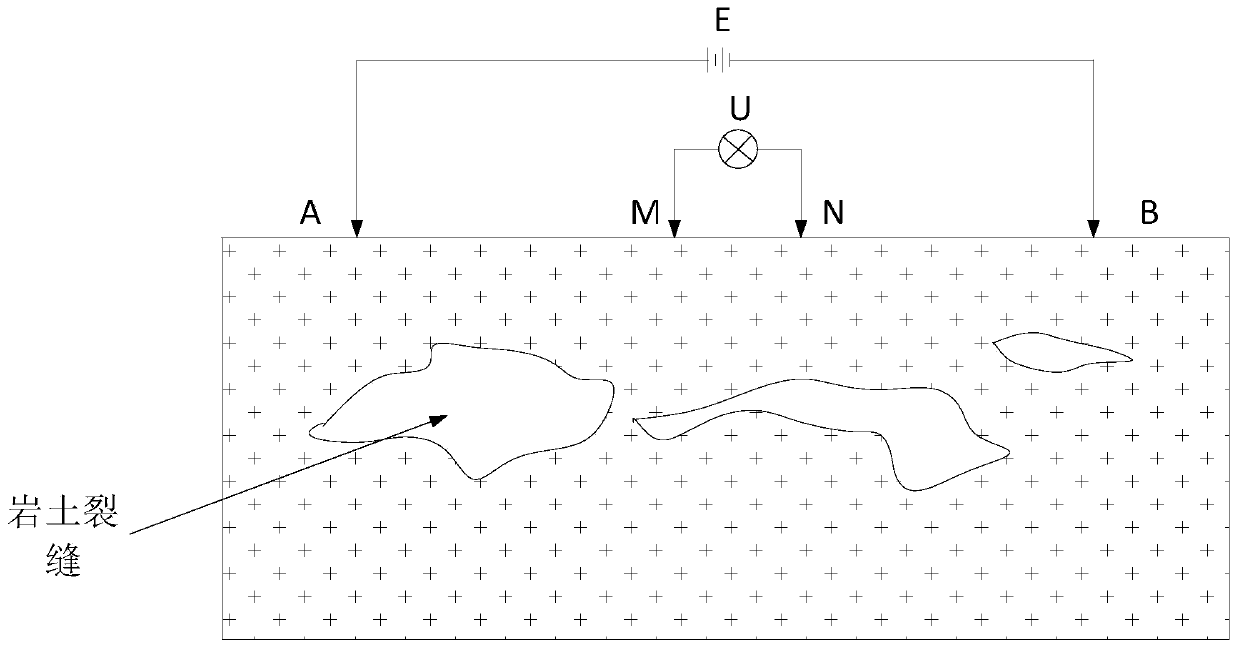

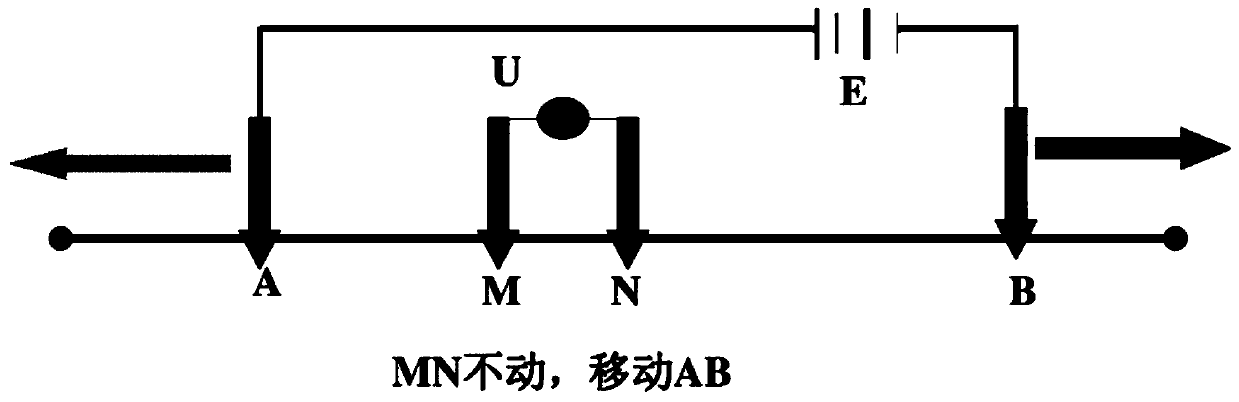

[0026] like Figure 1 to Figure 4 As shown, this embodiment provides a method for detecting and monitoring grouting materials utilizing differences in electrical conductivity, including the following steps:

[0027] In the first step, several electrodes are pre-embedded in the area to be grouted; in this embodiment, the depth of the pre-embedded electrodes is much lower than the depth of drilling, and it can not only provide quality inspection after grouting, but also provide The testing of the durability of grouting materials provides guarantee.

[0028] In the second step, the original resistance value of the area to be grouted is obtained by using the electrode method.

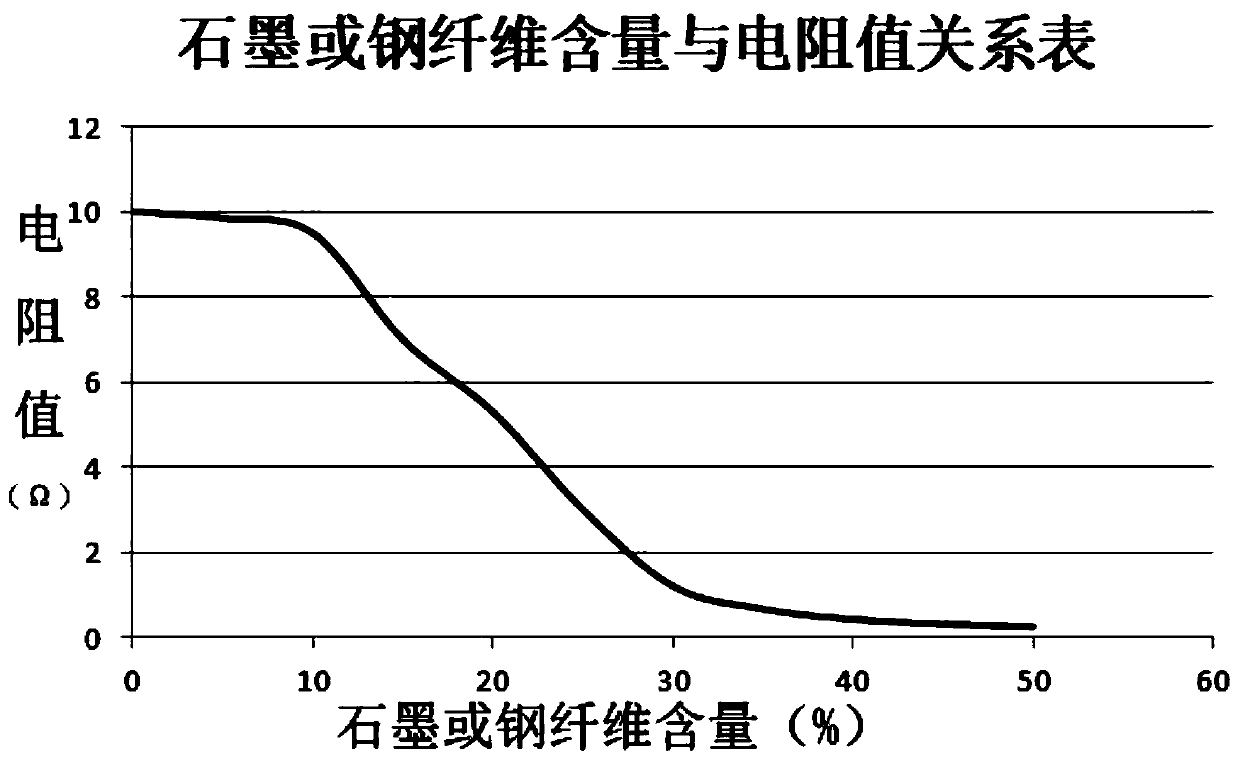

[0029] The third step is to adjust the type and proportion of the conductive material in the grouting material that utilizes the difference in electrical conductivity according to the original resistance value, and perform grouting in the area to be grouted; for example, in the grouting area of a certain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com