Octagonal working pit supporting member and mounting and construction method thereof

A working pit and octagonal technology, applied in excavation, infrastructure engineering, construction, etc., can solve problems such as complicated procedures, long construction period, sudden sinking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

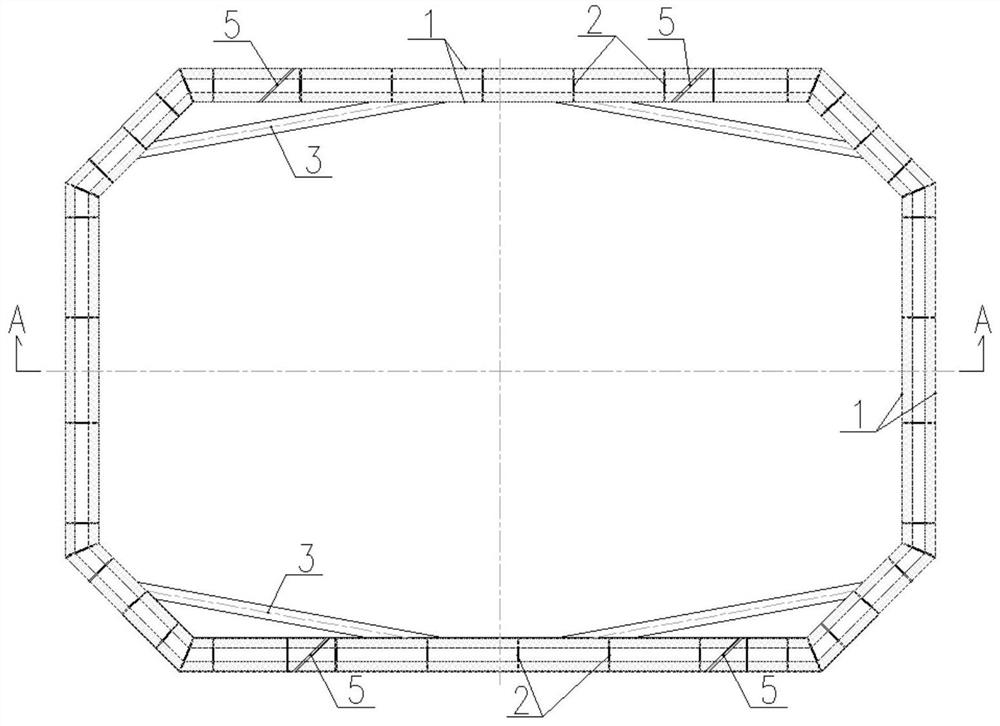

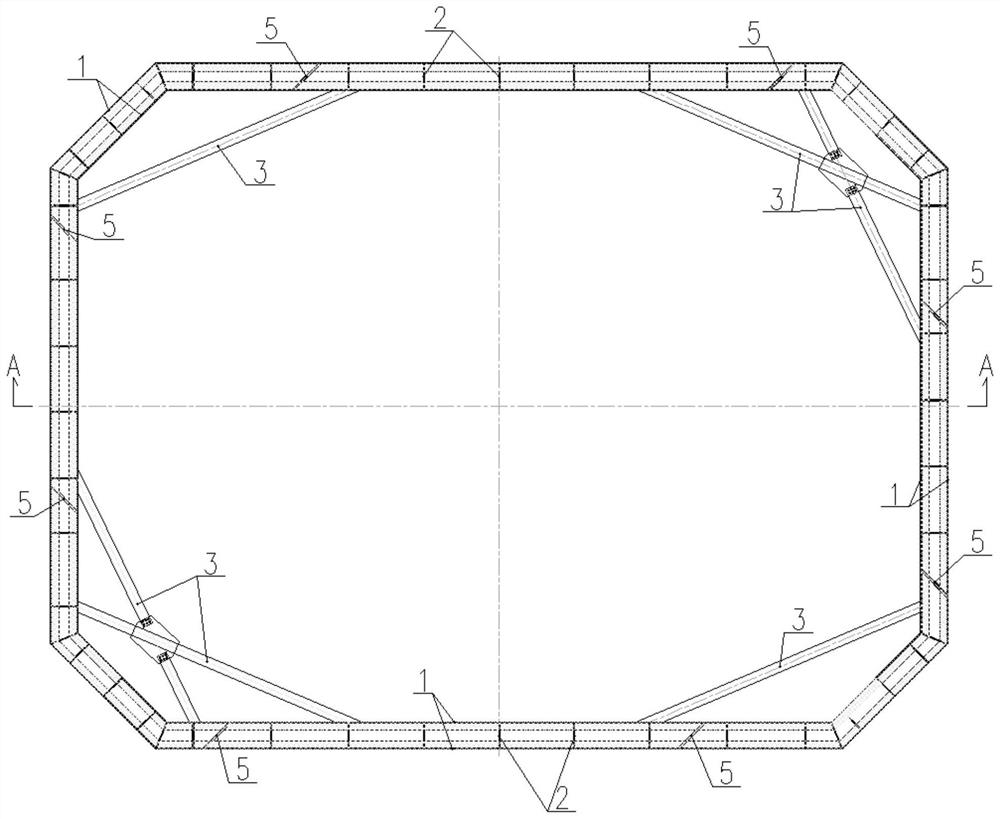

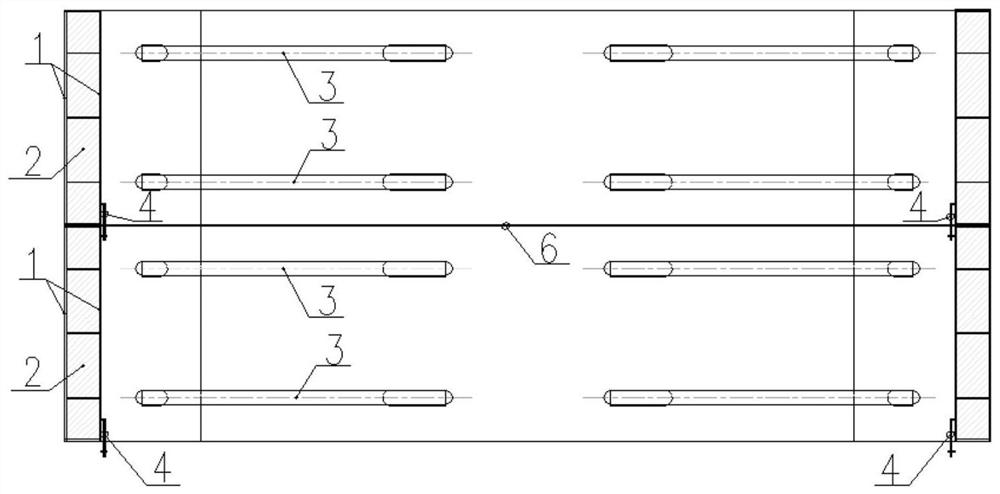

[0049] As shown in Figure 1(a) and (b), an octagonal working pit support member includes a frame-shaped working pit protection wall 1, and the working pit protection wall 1 is composed of inner and outer two layers of steel plates through steel plate stiffeners 2 are welded, and several steel plate stiffeners 2 are arranged at equal intervals between the inner and outer steel plates along the working pit protection wall 1.

[0050] In one embodiment, the steel plate stiffener 2 includes a vertical plate and two horizontal stiffeners connected therebetween, so that the force is uniform and the structure is firm. The vertical plate is welded at 90° along the inner and outer steel plate wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com