A roof and bottom shared underground structure and its separate construction method

A technology of underground structure and construction method, which is applied to underwater structures, infrastructure engineering, buildings, etc., can solve problems such as inapplicability of underground structures, large underground available space, and inapplicability of underground structures, so as to ensure construction safety, Save underground space and reduce construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

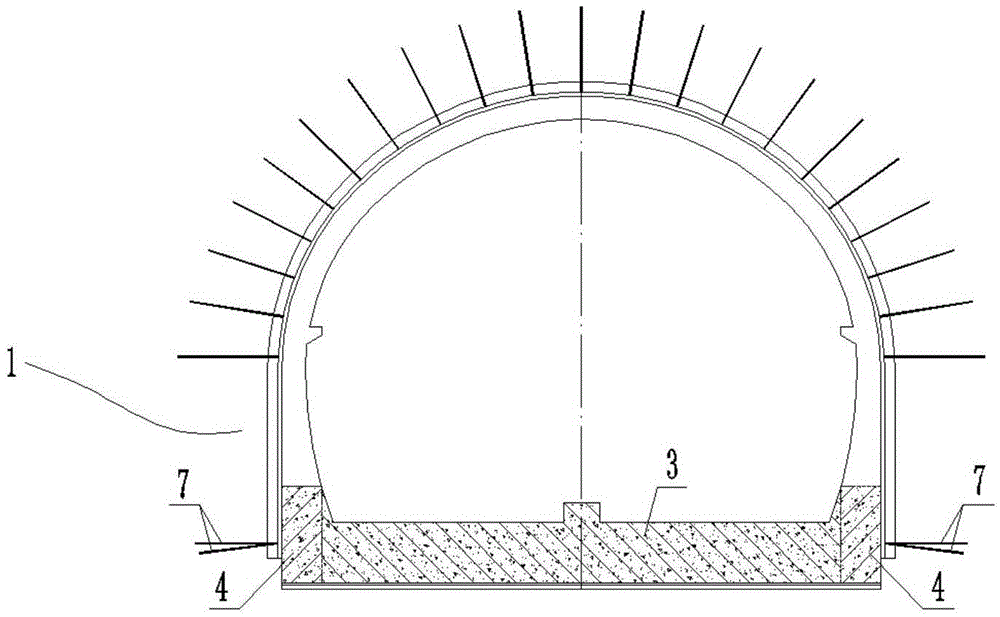

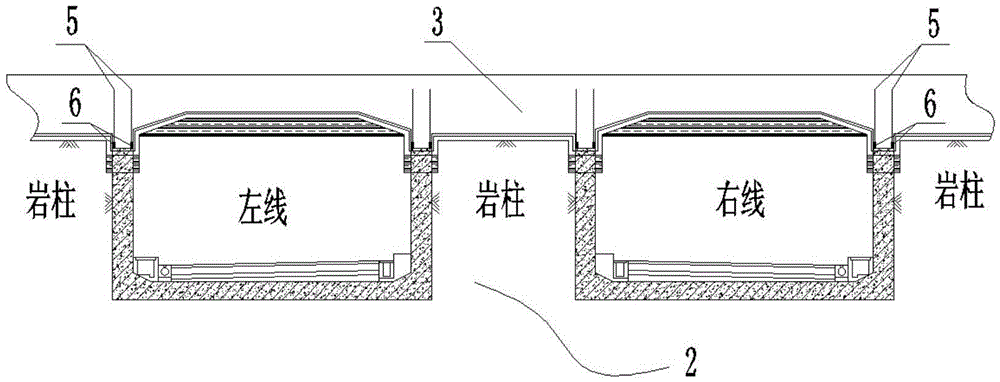

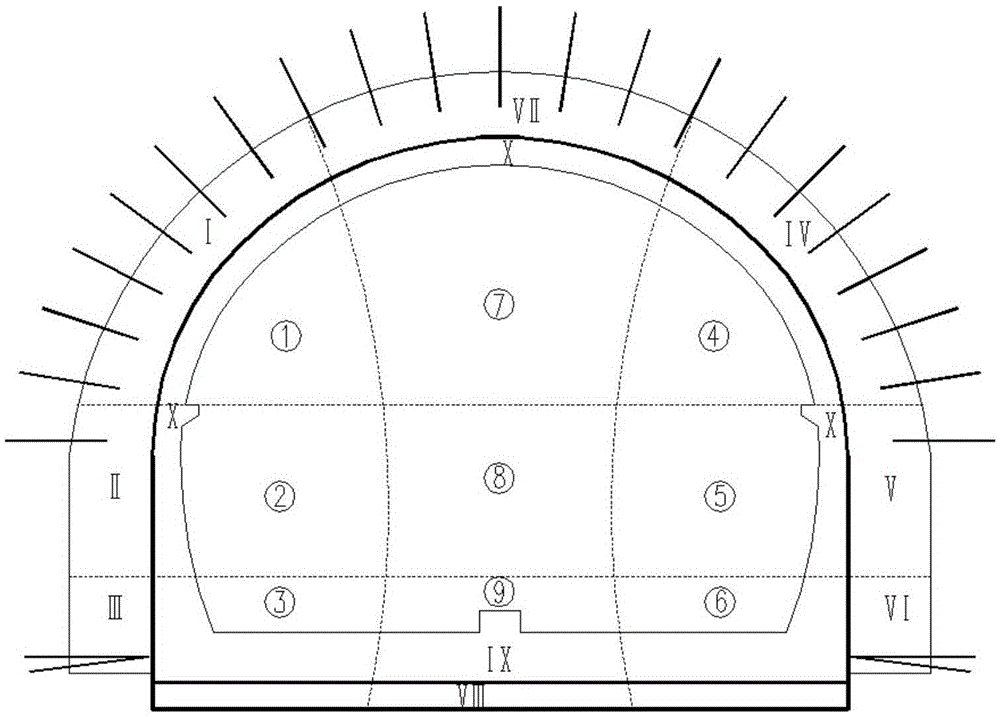

[0038] As shown in the figure, the top and bottom shared underground structure in this embodiment includes an upper structure 1, a lower structure 2 and a partition 3 arranged between the upper and lower structures for the two-layer structure. The upper structure 1 and the lower structure 2 Orthogonal arrangement, the upper structure 1 is a curved wall arch structure with a flat bottom; the lower structure 2 is a separated double-span rectangular frame structure, and the upper structure 1 has side wall feet and partitions 3 There are hidden beams 4 corresponding to each other, and the partitions 3 and the lower rectangular frame structure are fastened by steel bars. Specifically, the superstructure 1 is an arched flat-bottomed island-type station structure with five-center garden curved walls, and the substructure 2 is a separated double-sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com