Assembly type building energy conservation and heat preservation wall and manufacturing and assembling method thereof

A technology for building energy-saving and thermal insulation walls, which can be used in construction, building components, sustainable buildings, etc., and can solve problems such as exploration and research.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

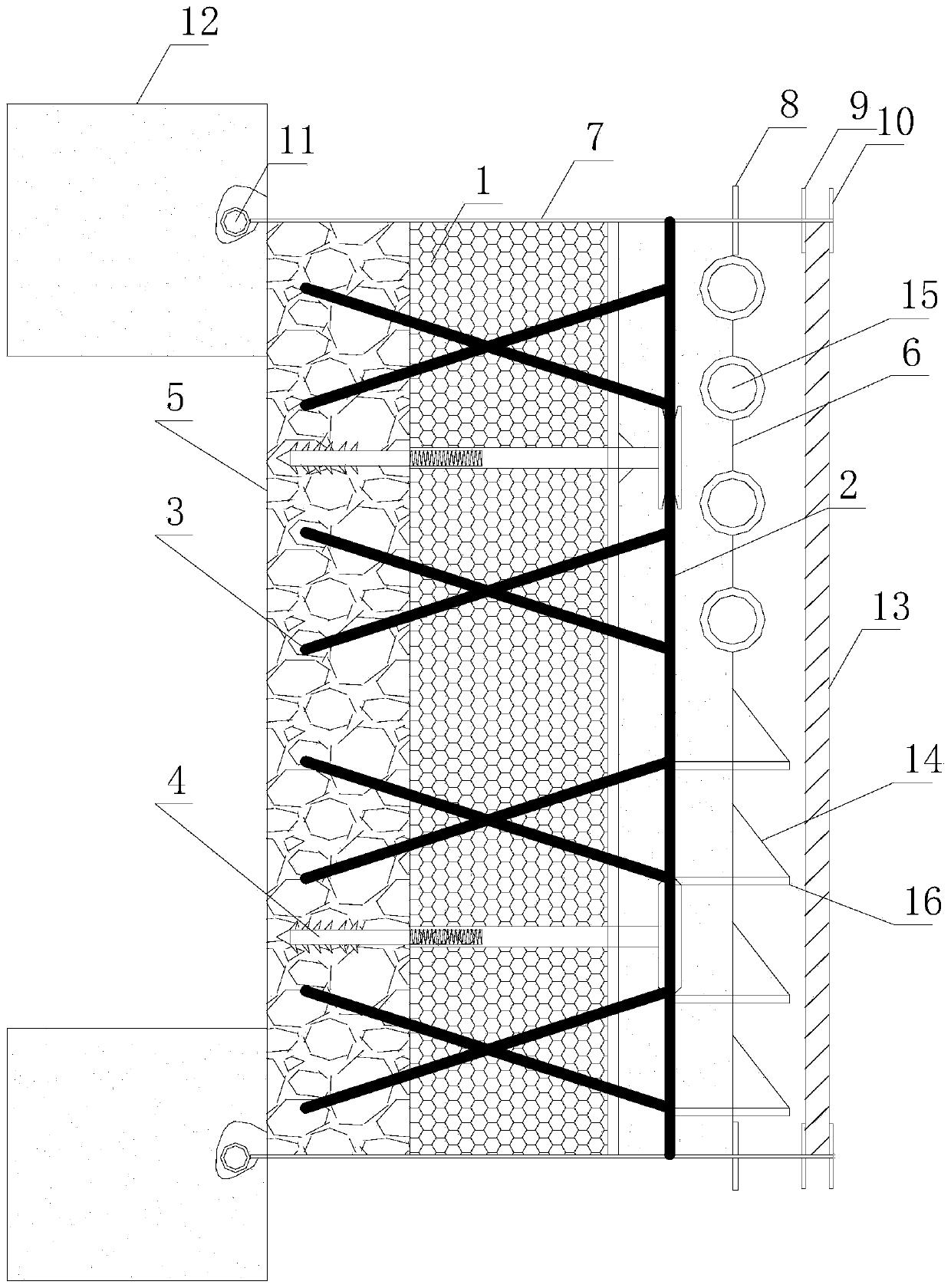

[0030] The technical solution will be described in detail below in conjunction with the accompanying drawings and specific embodiments

[0031] As shown in the figure, a prefabricated building energy-saving and thermal insulation wall includes a middle thermal insulation layer 1, a steel wire grid, a split screw 4 and a fixed assembly frame 7, and a concrete layer 5 and thermal insulation mortar are arranged on both sides of the thermal insulation layer 1. layer 6, the steel wire mesh frame includes oblique wires 3 and steel wire mesh 2, the steel wire mesh 2 is located in the thermal insulation mortar layer 6, one end of the oblique wire 3 is welded on the steel wire mesh 2, and one end passes through And extend the insulation layer 1;

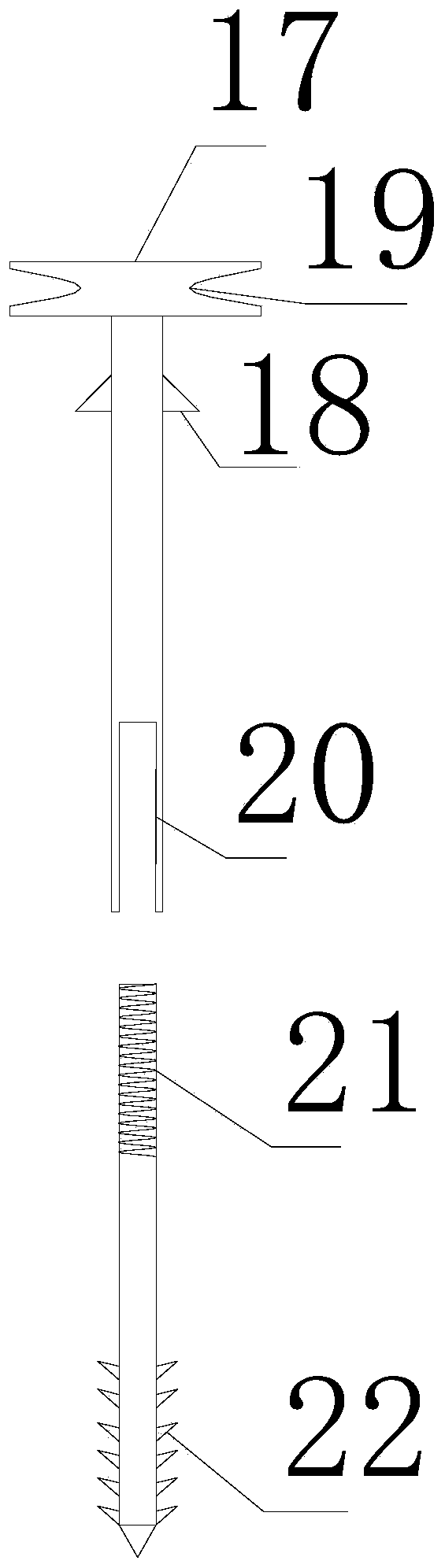

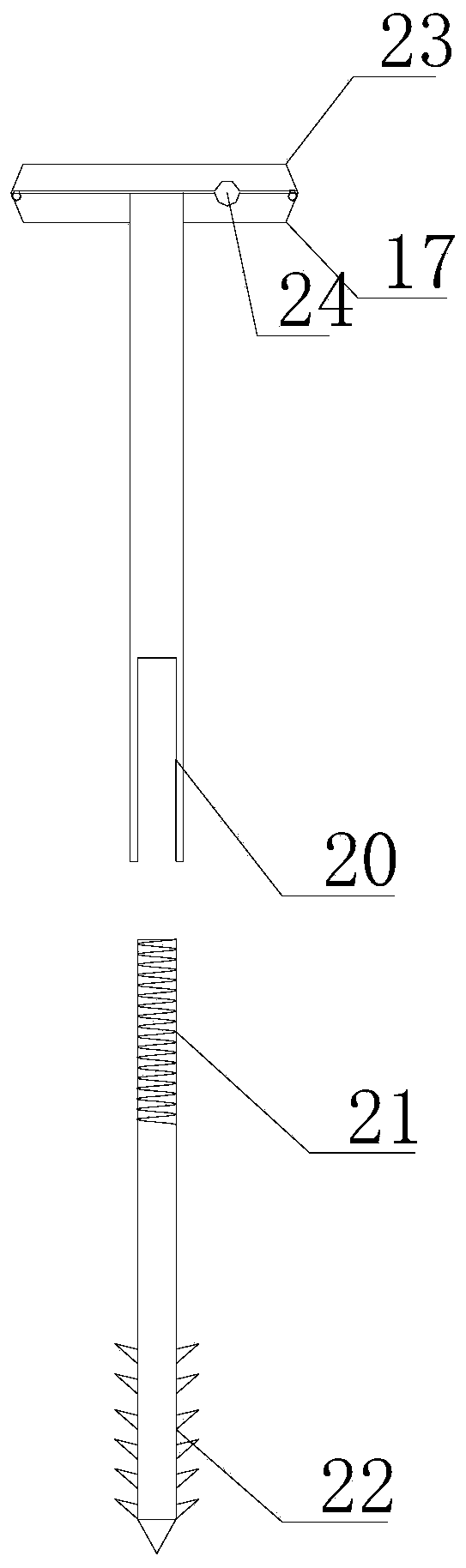

[0032] The split screw 4 includes a screw rod and a barrel rod. One end of the barrel rod is provided with a screw cap 17, and the other end is designed with an inner wire 20 matched with the outer wire 21 of the screw rod. The other end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com