Continuous injecting and acidizing unit for water injection well

A technology for water injection wells and equipment, applied in wellbore/well components, production fluids, earthwork drilling, etc., can solve the problems of high labor intensity, complex process, high operating costs, simplify construction operations, reduce water injection pressure, labor Intensity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

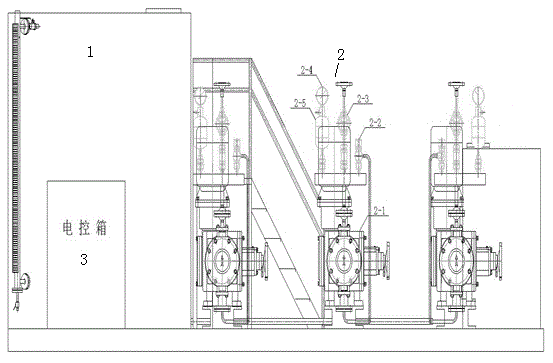

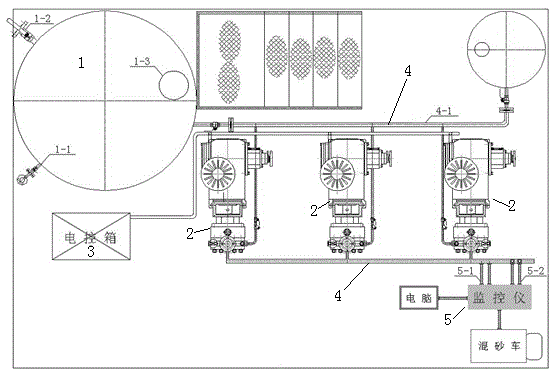

[0023] Such as figure 1 and figure 2 Shown is a continuous injection acidification equipment for water injection wells. The present invention is a mobile integrated online acidification device, which consists of an acid liquid storage tank 1, a hydraulic double-diaphragm metering pump 2, a control system 3, and an acid liquid pipeline system 4 , online monitoring system 5, truck moving system, in which the acid liquid storage tank 1 is connected with the hydraulic double diaphragm metering pump 2, the outlet of the hydraulic double diaphragm metering pump 2 is connected with the acid liquid pipeline system 4, and the control system 3 is connected with the hydraulic double diaphragm metering The pump 2 is connected, the on-line monitoring system 5 is connected with the acid pipeline system 4, the common steel base of the acid storage tank 1, the hydraulic double-diaphragm metering pump 2 and the control system 3 is connected with the chassis of the truck mobile system.

Embodiment 2

[0025] On the basis of Embodiment 1, the number of the hydraulic double-diaphragm metering pumps 2 is three, and the working state is set as two open and one standby. The specific connection method between the acid liquid storage tank 1 and the hydraulic double-diaphragm metering pump 2 is: the bottom of the acid liquid tank 1 is connected with a ball valve through a pipeline, the ball valve is connected with a Y-type filter, the Y-type filter and the hydraulic double-diaphragm metering pump The inlet of 2 is connected, the acid liquid is filtered through the Y-type filter and enters the hydraulic double-diaphragm metering pump 2, and the liquid is pressurized by the hydraulic double-diaphragm metering pump 2 and then enters the wellhead through the acid liquid pipeline system 4. The acid liquid storage tank 1 is composed of a magnetic flap liquid level gauge 1-1, a sewage outlet 1-2, and a dosing port 1-3. The acid liquid is added through the dosing port, and the liquid level ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com