Multi-layer pipe rack structure of deep pipe rack foundation pit and construction method of multi-layer pipe rack structure

A construction method and technology of pipe gallery, which are applied in infrastructure engineering, underwater structures, artificial islands, etc., can solve the problems of narrow support space of pipe gallery, inability to effectively complete the construction of pipe gallery, etc., so as to shorten the construction period and simplify the formwork. The effect of building work and speeding up the construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

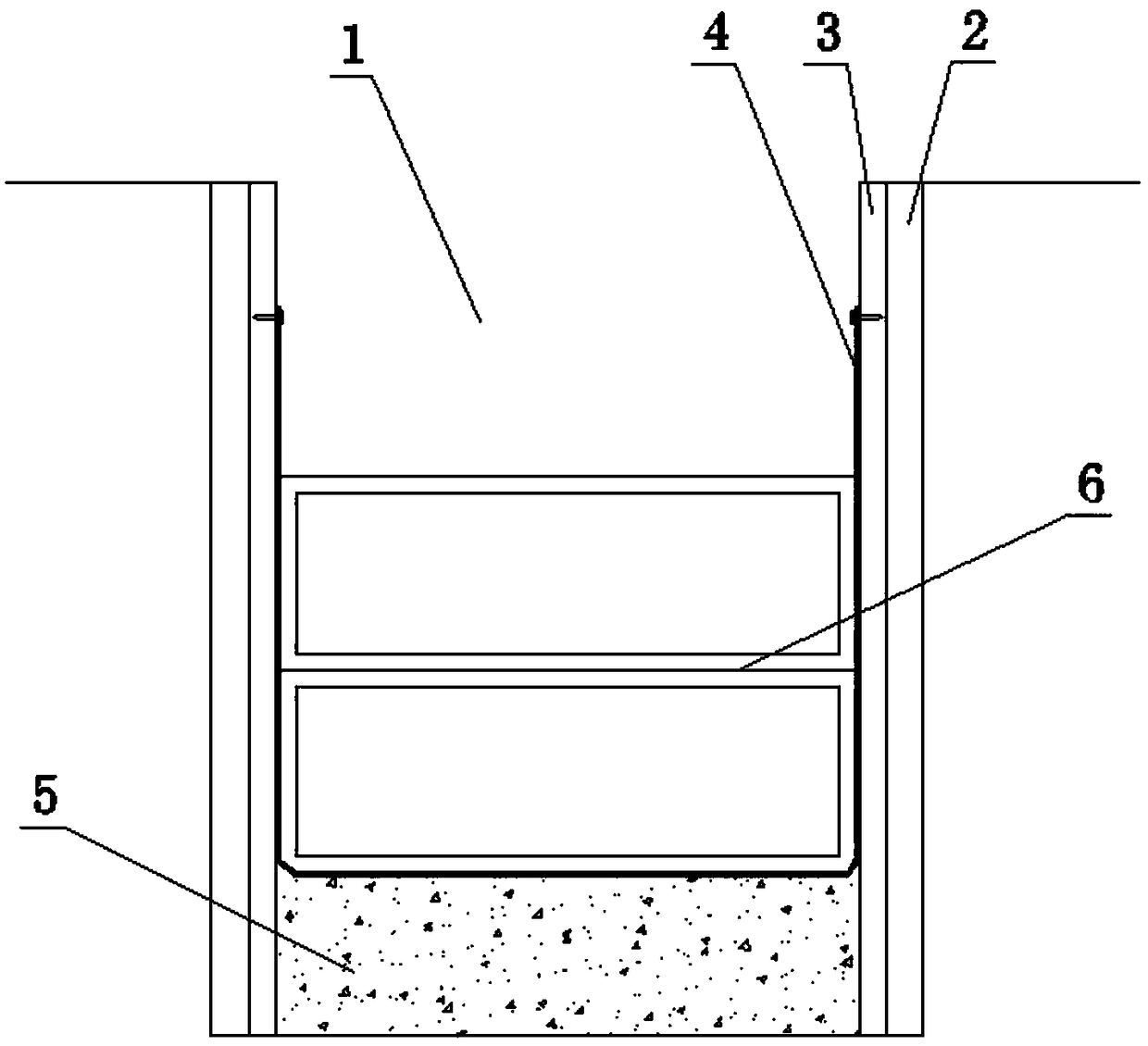

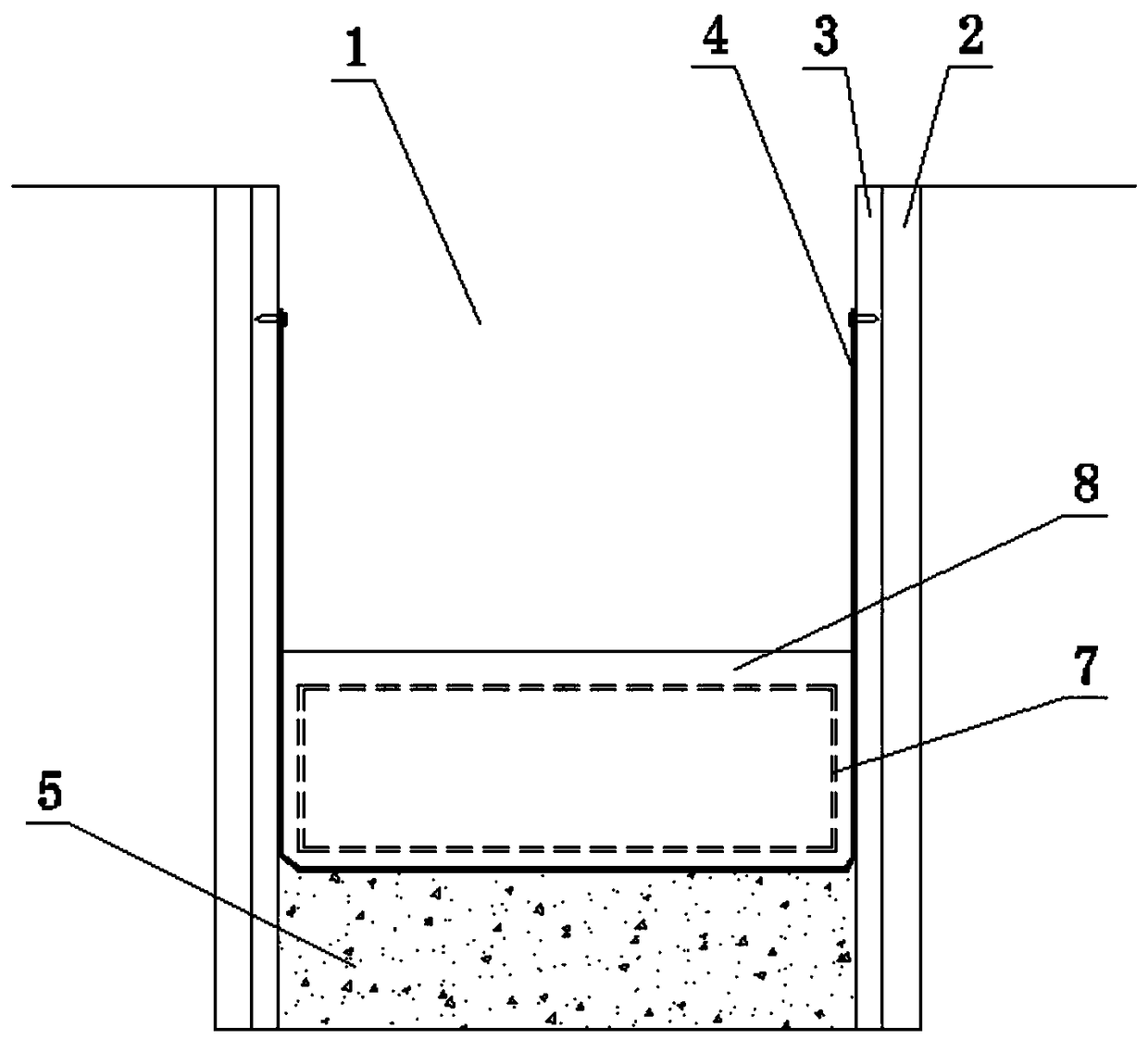

[0023] The present invention will be described in further detail below in conjunction with accompanying drawing, so that those skilled in the art can understand more clearly, as figure 1 As shown, the multi-layer pipe gallery structure of the deep pipe gallery foundation pit of the present invention includes a pipe gallery foundation pit 1, two rows of bored piles 2 are arranged on both sides of the pipe gallery foundation pit 1, and the pipe gallery foundation The steel mesh is fixed on the right outer wall of the bored pile 2 on the left side of the pit 1, and the steel mesh is fixed on the left outer wall of the bored pile 2 on the right side of the pipe gallery foundation pit 1, and the steel mesh is sprayed with concrete to form a shotcrete layer 3. A layer of concrete cushion 4 is poured on the bottom surface of the foundation pit 1 of the pipe gallery, and a layer of waterproof roll material 5 is laid on the concrete cushion layer 4. The slurry layer 3, the left and rig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com