High-dipping ore block house column mining method

A mining method and steep inclination technology, which are applied in the field of mining steeply inclined ore bodies, can solve the problems that it is difficult for operators to reach the site where there is no work on the working surface, ventilation, blocking of pedestrian and wind flow passages, and high ore loss rate, etc. Achieve the effect of good ventilation, improved working environment and high ore recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

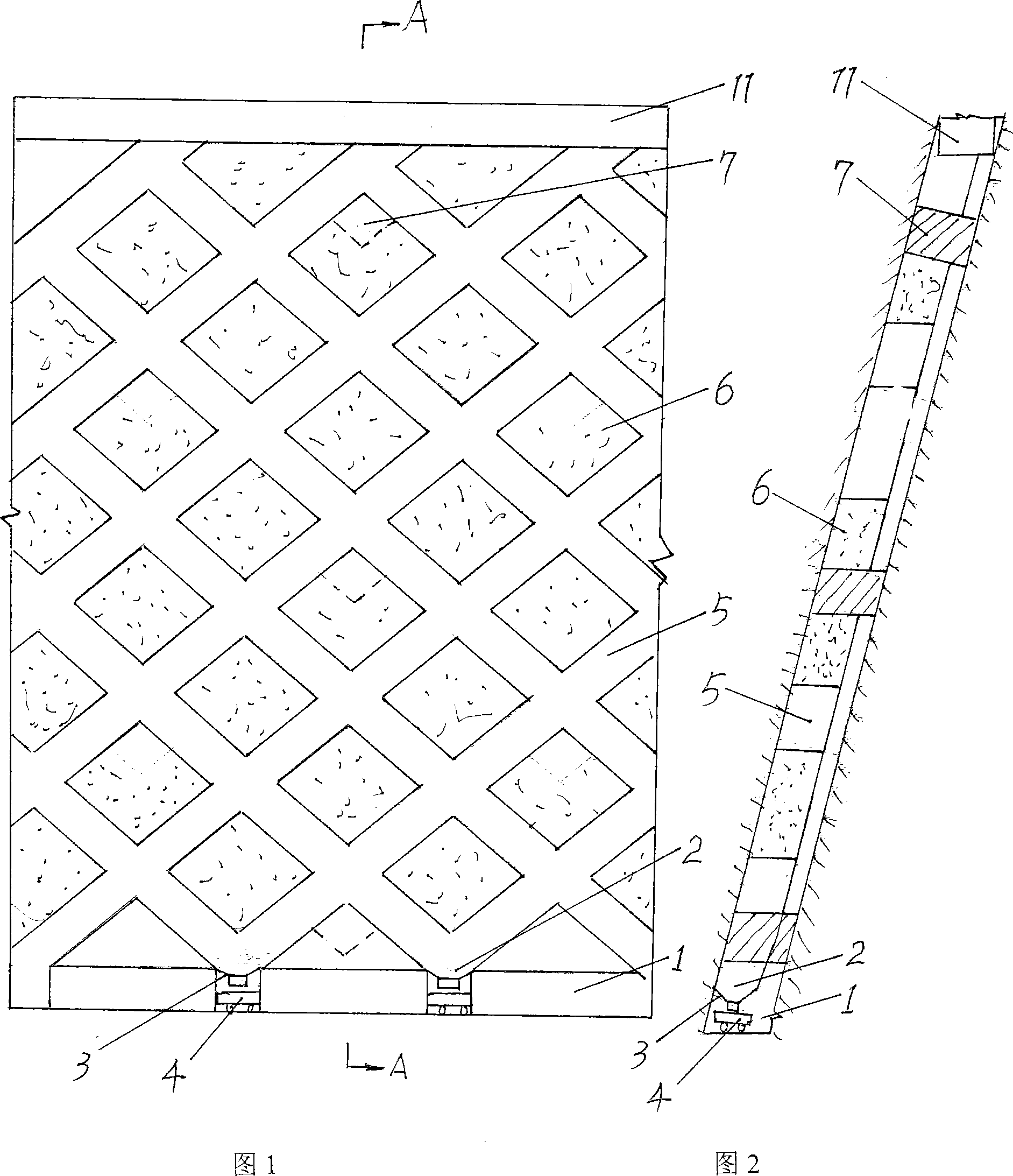

[0020] A. At the bottom of the steeply inclined ore body, excavate a transport roadway 1 along the direction of the ore body. The roadway is 2.5 meters wide and 2 meters high, and is used to export ore and serve as a pedestrian passage and wind flow passage;

[0021] B. In the transportation roadway 1, excavate the ore-feeding groove 2 every 10 meters, install the ore-drawing funnel 3 on the groove 2, place the mine car 4 under the funnel 3, and place the ore-falling groove 2 on the ore-falling groove 2. Trough 2 is the intersection point, and two inclined shafts 5 are excavated uphill to the top of the stope. Each inclined shaft forms a 45° angle with the horizontal line, and the width of the inclined shaft is about 3 meters. During the excavation, rock drilling and explosive blasting are used. Carry out; the mined ore slides by its own weight along the inclined shaft 5 to the ore-drawing funnel at the intersection point, and then puts it into the mine car 4 in the transportat...

Embodiment 2

[0025] A. On the steeply inclined ore body, excavate the transport roadway 1 along the direction of the ore body. The roadway is 2.2 meters high and 2 meters high, which is used to export ore and serve as a pedestrian passage and ventilation passage;

[0026] B. In the transportation roadway 1, excavate the ore falling groove 2 every 10 meters, install the ore funnel 3 on the groove 2, place the mine car 4 under the funnel 3, and use the ore falling groove 2 on the ore falling groove 2 2 is the intersection point, and two inclined shafts 5 are excavated uphill to the top of the stope. Each inclined shaft forms a 43° angle with the horizontal line, and the width of the inclined shaft is 3 meters. During the excavation, rock drilling and explosive blasting are used. The mined ore slips by its own weight along the inclined shaft 5 to the ore-feeding groove 2 at the intersection point, and then falls into the mine car 4 in the transportation roadway 1 through the funnel 3 and is se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com