Mining method of efficient big collapse area ore mining

A mining method and ore technology, which is applied in ground mining, mining equipment, underground mining, etc., can solve problems such as long cycle time, large amount of support engineering, and low mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

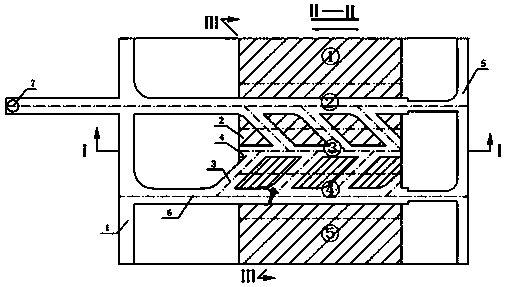

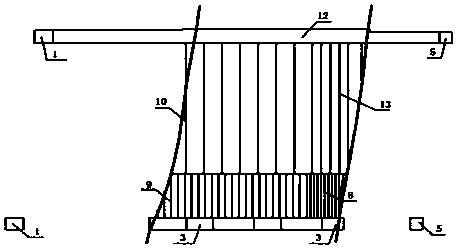

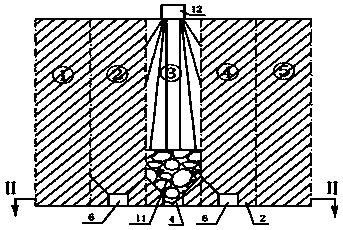

[0031] See attached picture.

[0032] The low-concentration fine tailings are cemented and filled in the collapsed area, so that the ore is consolidated into a whole, and a mining method for efficient mining of ore in a large collapsed area is adopted. The specific implementation steps are as follows:

[0033] Stope layout

[0034] The length of the stope is 40m thick, the width is 12m, and the height is 50m. A large-diameter blasthole rock drilling roadway 12 is constructed in the middle of the upper and middle section of the stope. Diameter blast hole 10 falls ore. Drilling roadway 4 at the bottom of the stope is densely drilled by the middle blasthole to squeeze the blasting groove, and the blasting of the middle blasthole forms a V-shaped ore-receiving cutting ditch 11, and the 6m³ scraper is transported from the exit roadway 6 on both sides of the stope to the chute, and the chute 7 Arranged on the other side of the transportation roadway 1 along the footwall, the stop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com