High-temperature high-pressure fluid solid-phase deposition simulation device

A technology of high temperature and high pressure, simulation device, applied in the field of solid phase deposition, can solve the problems of easy occurrence of solid phase deposition, reservoir damage and blockage, and difficulty in mining, and achieves the effect of facilitating oil reservoir development, avoiding blockage and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

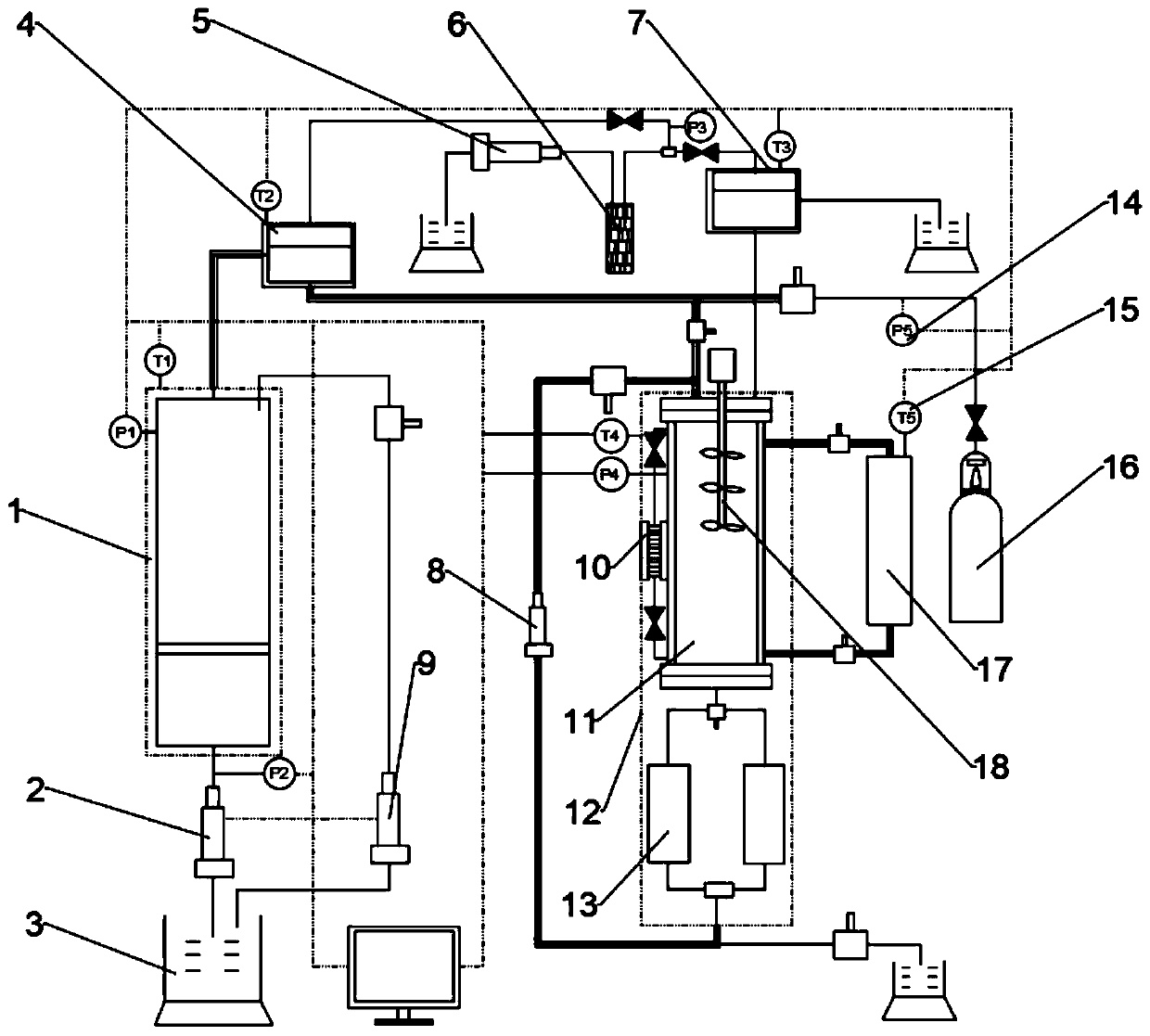

[0039] figure 1 It shows a schematic structural diagram of an embodiment of the present invention. This embodiment relates to a high-temperature and high-pressure fluid solid-phase deposition simulation device, which is used to detect the amount of solid-phase deposits in oil and gas. By changing the fluid pressure and temperature in the sample cylinder, To obtain the solid phase deposits, and to detect the amount of solid phase deposits in the fluid through filtration collection and weighing, to solve the problem of underlying fluid channels and wellbore solid phase deposition, and to avoid reservoir damage and blockage and wellbore blockage.

[0040] The above-mentioned filtration collection and weighing method is to filter the solid-phase sediment in the fluid through a filter, take out the filtrate, dry and weigh it, and obtain the total am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com