Mounting base

一种安装基础、基座的技术,应用在特殊基础布置、基础结构工程、发热装置等方向,能够解决无法基础安装、无法降低基础施工劳动力、成本等问题,达到简化施工作业、缩短施工工期的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

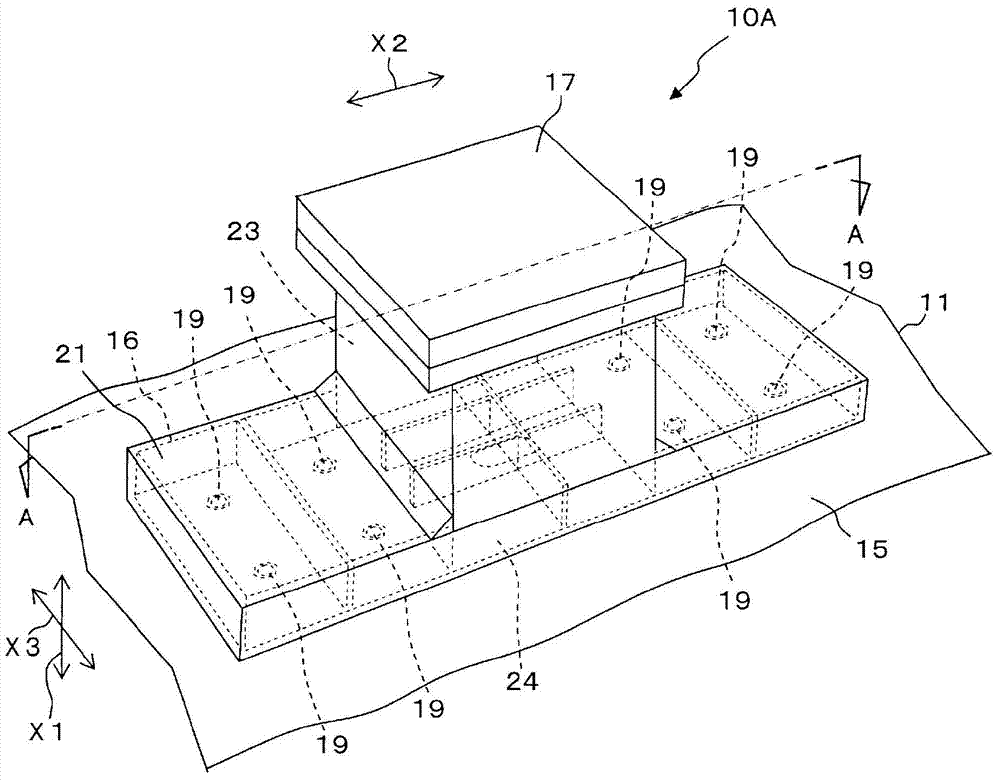

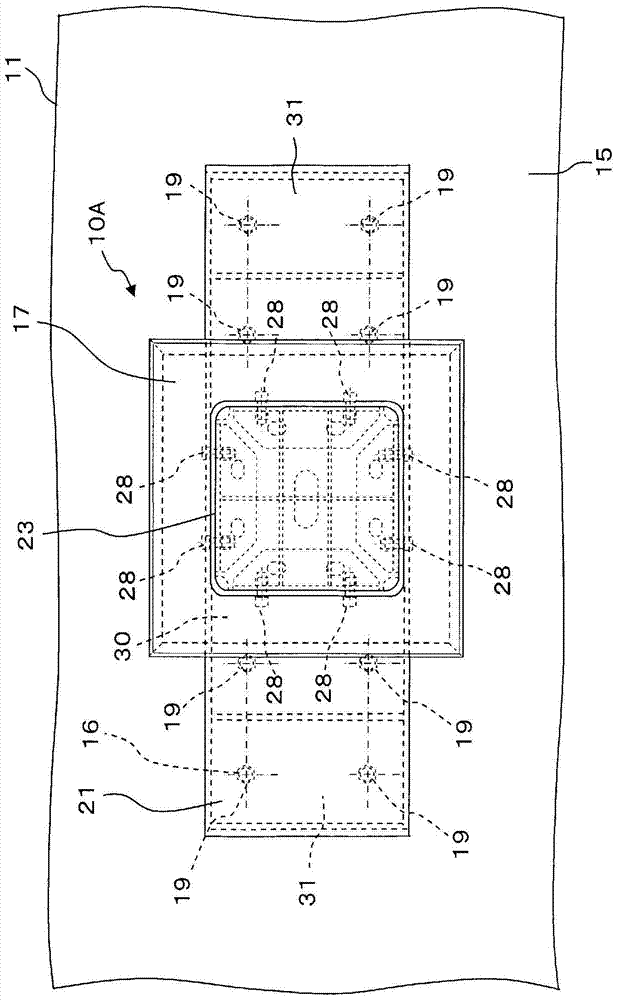

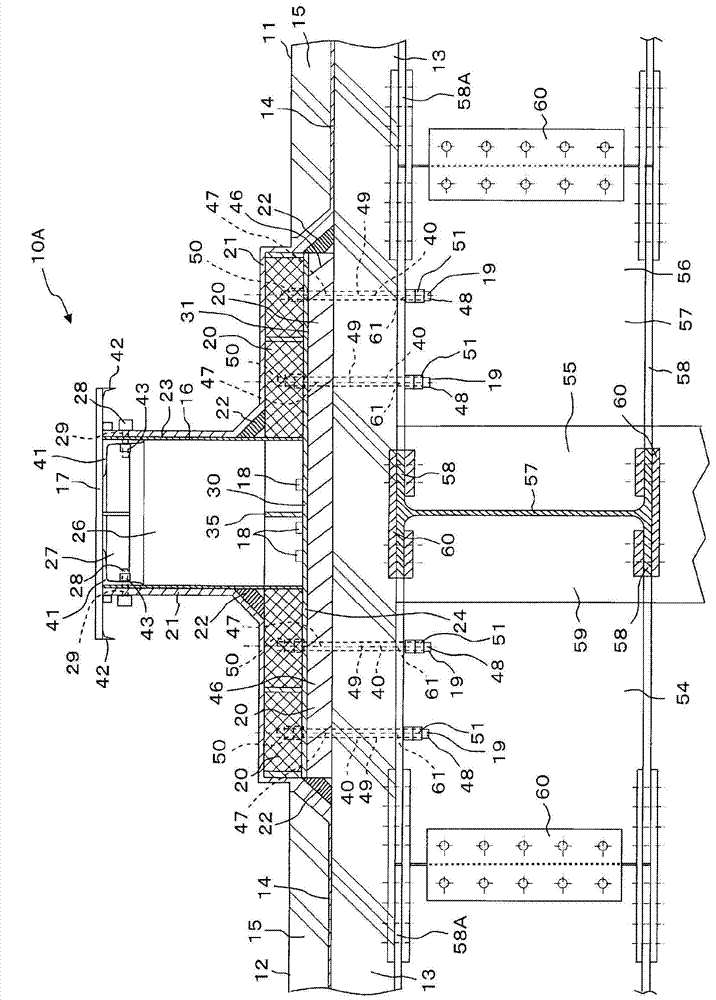

[0058] Referring to the perspective view of the mounting base 10A shown as an example figure 1 The installation base of the present invention is described in detail with accompanying drawings, content is as follows. exist figure 1 The figure shows one installation foundation 10A installed on the steel frame structure 11, but the number of foundations 10A is not limited to the number shown in the figure, generally speaking, two Above foundation 10A. in addition, figure 2 is a top view of the mounting base 10A, image 3 Yes figure 1 A-A sectional view of . Figure 4 is a top view of the metal base 16, Figure 5 is a side view of the metal base 16 . exist figure 1 Here, the up-down direction is indicated by an arrow X1, the lateral direction is indicated by an arrow X2, and the front-rear direction is indicated by an arrow X3.

[0059] The installation base 10A is installed at a predetermined installation position on the roof or underground of a steel frame structure 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com