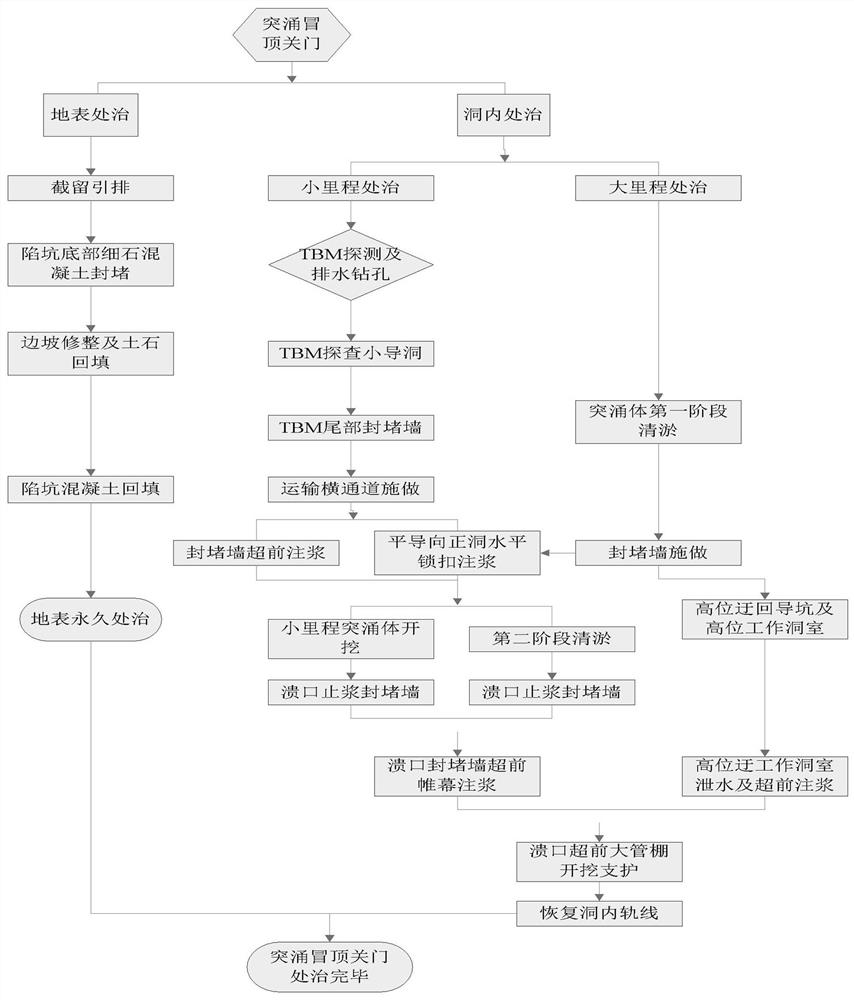

Tunnel gushing roof fall door closing treatment method

A technology of sudden surge and tunnel, which is applied in the field of tunnel sudden surge and roof collapse, can solve problems such as loss, sudden surge and roof fall, and achieve the effect of strong applicability, short construction period and rapid construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

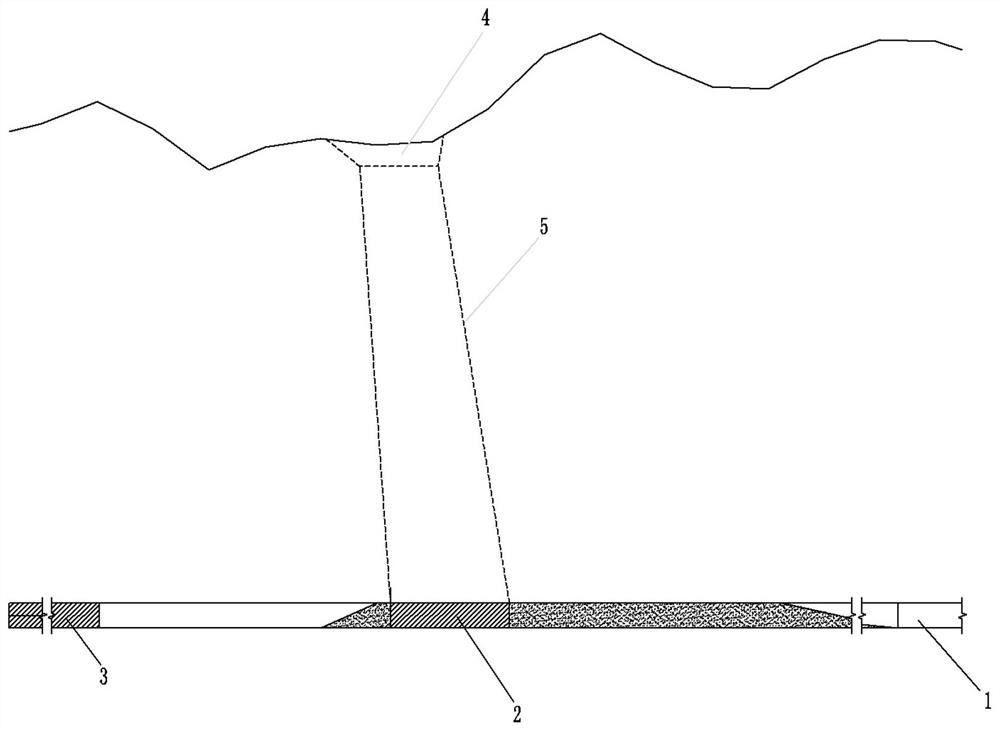

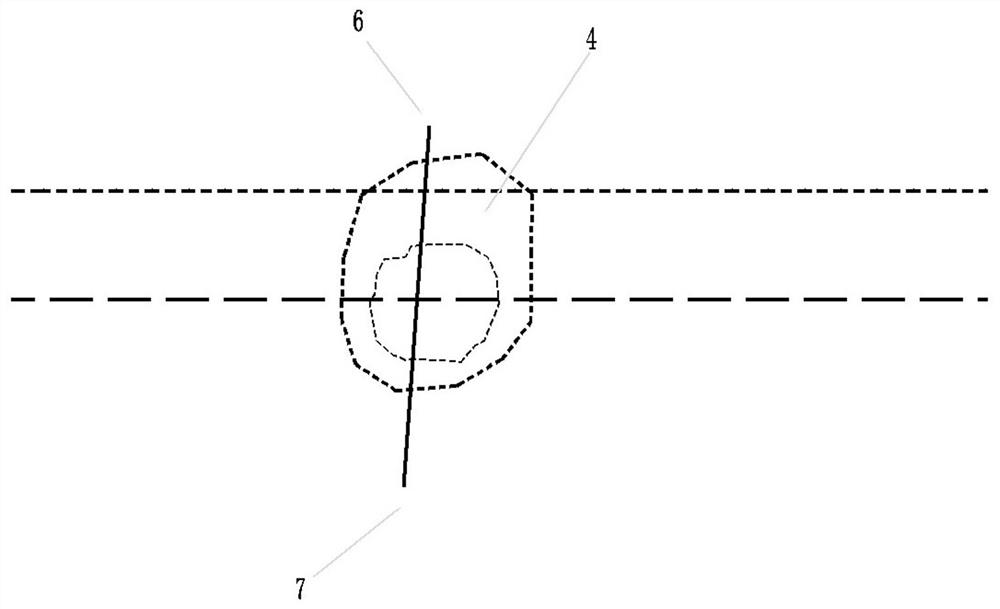

[0039] Embodiment 1: Application example of tunnel surge and roof fall and door closing treatment

[0040] Project overview: The Gaoligongshan Tunnel of the Dali-Sui Railway is located in the section from Nujiang Station to Longling Station, with a total length of 34.538km. The whole tunnel is located in a straight line. The longitudinal slope of the line in the tunnel is a herringbone slope with a maximum gradient of 23.5‰; the maximum buried depth of this tunnel is 1155m.

[0041] The auxiliary tunnel of this tunnel is set as "1 level + 1 slope + 2 vertical", and the whole tunnel is divided into 5 work areas including the entrance, the No. 1 inclined shaft, the No. 1 shaft, the No. 2 shaft and the exit. Among them, the exit work area is the TBM work area, and the main tunnel and the horizontal guide are mainly constructed by TBM. The difficult section of TBM construction and the entrance section are constructed by drilling and blasting method, and the TBM is passed through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com