Steel truss jacking device

A steel grid and jacking technology, which is applied in the fields of construction, building structure, and building materials processing, can solve the problems of unusable, difficult assembly, difficult assembly quality and safety control, etc. Practical and guarantee the effect of verticality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

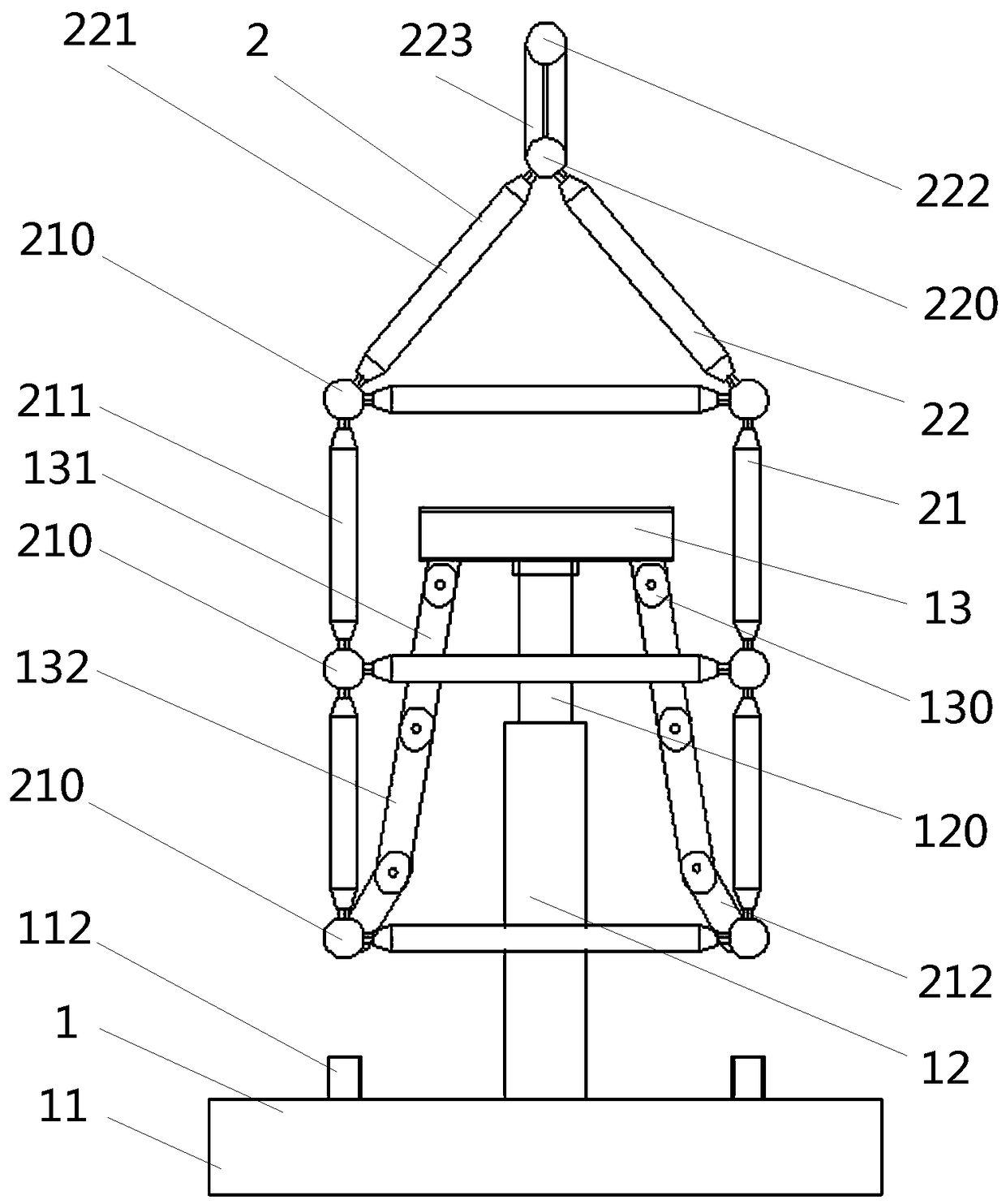

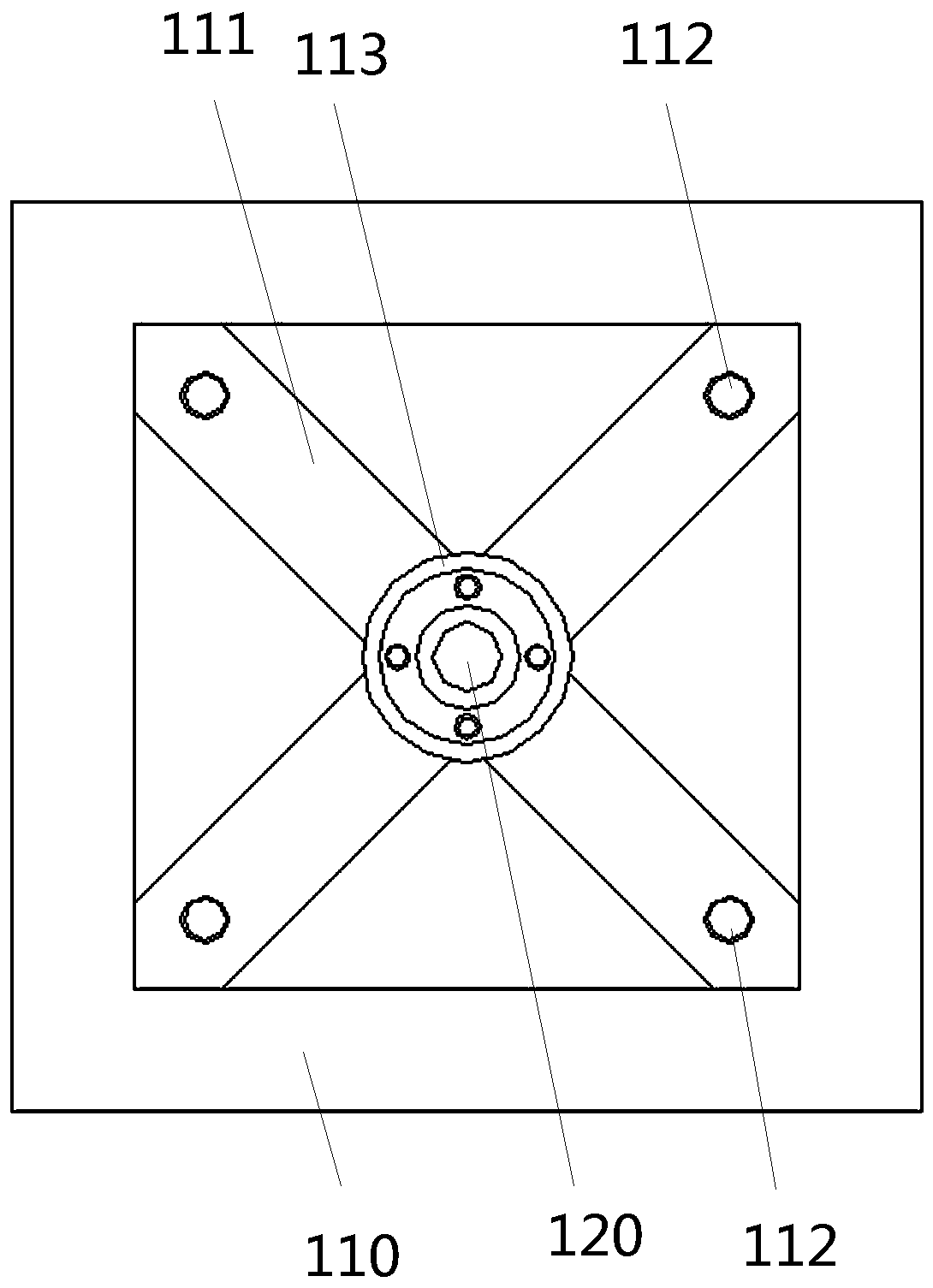

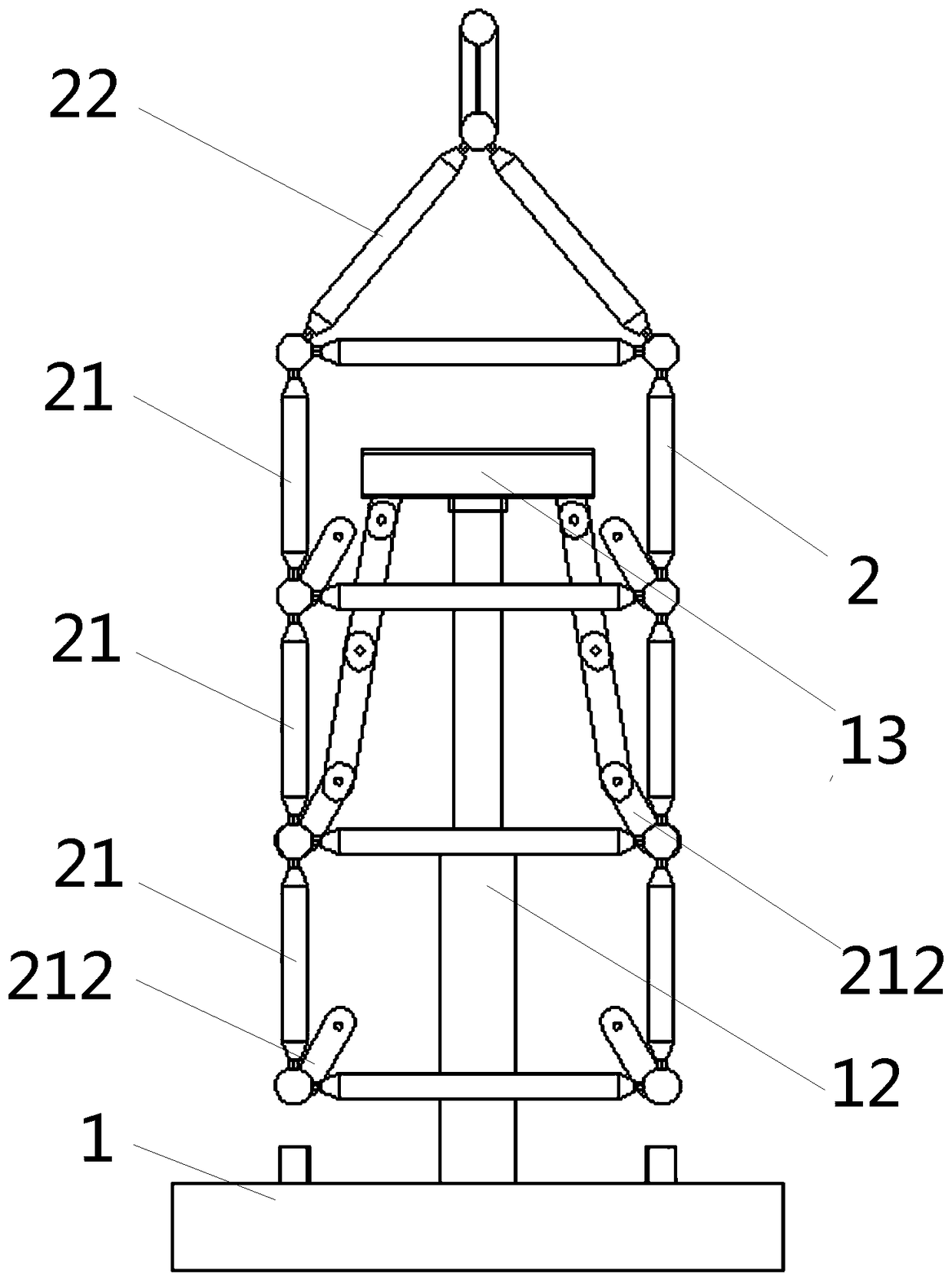

[0025] Embodiment 2, steel grid lifting equipment, the base 11 includes a rectangular support base 110, two inclined beams 111 are connected between the four corners inside the rectangular support base 110, and the intersection of the two inclined beams 111 is passed through a flange plate 113 is fixedly connected to the jack 12, with the axis of the jack 12 as the symmetric line, two mutually symmetrical jacking frame supports 112 are arranged on the two inclined beams 111, and the jacking frame supports 112 correspond to the standard section 21 of the lattice column up and down . The support 112 of the jacking frame is provided to support stably when the jack 12 falls back and when the jacking frame 2 raises the steel grid frame to the elevation, which not only facilitates the installation of the next lattice column standard section 21, but also facilitates the installation of the steel grid. The stable support after the top of the rack is raised to the elevation.

[0026] ...

Embodiment 3

[0027] Embodiment 3, steel grid frame jacking equipment, each of the jacking frame supports 112 corresponds to the four bolt balls 210 below the lattice column standard section 21 up and down, and the jacking frame supports 112 and the bolt balls 210 are on top of each other The upper end surface of the joint is provided with a spherical groove having the same spherical radian as the bolt ball 210 . Setting spherical grooves can further ensure the stability of the support.

[0028] Other structures of this embodiment are the same as those of Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com