Overmined-goaf coal-bed methane surface well drilling method

A technology for surface drilling and passing through gobs, which is applied to surface mining, drilling equipment, and driving devices for drilling in boreholes. It can solve problems such as failure to establish normal circulation, increase safety hazards in underground production in coal mines, and loss of drilling fluid. To achieve the effect of ensuring safe and efficient construction, ensuring safe and efficient progress, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

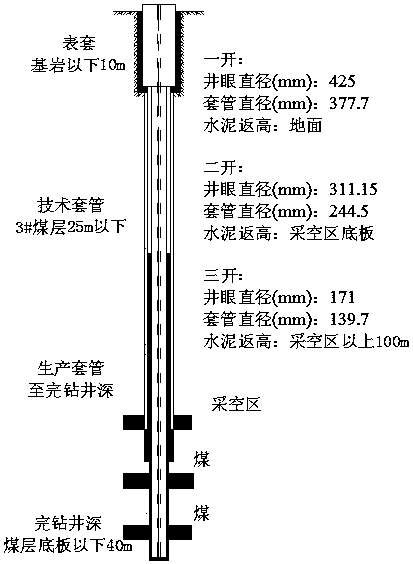

[0019] A ground drilling method for coalbed methane in a goaf, the specific implementation method is as follows:

[0020] The known conventional drilling method is adopted in the first stage, and the drilling tool combination is Φ425.00mm impactor bit + double male joint + Φ168.00mm drill collar + adapter + drill pipe. Corresponding drilling parameters were adopted for the drilling tools. The first section was used to prevent deflection, and the method of hoisting with small drilling pressure was adopted, and the drilling was drilled to 10m below the bedrock; the 377.7mm casing was run in, and conventional density cement was used for cementing , the cement returns to the surface.

[0021] Air drilling is used in the second opening, and the drilling tool combination is Φ311.15mm air down-the-hole hammer bit + one male and one female bit + Φ168.00mm drill collar + adapter + drill pipe, and then nitrogen drilling is used. When the target coal seam floor is 90m above the floor, n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com