Method for high beam falling construction based on push method

A technology of jack-up method and beam-dropping, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as permanent pier damage, avoid damage, shorten the construction period of falling beams, and save materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

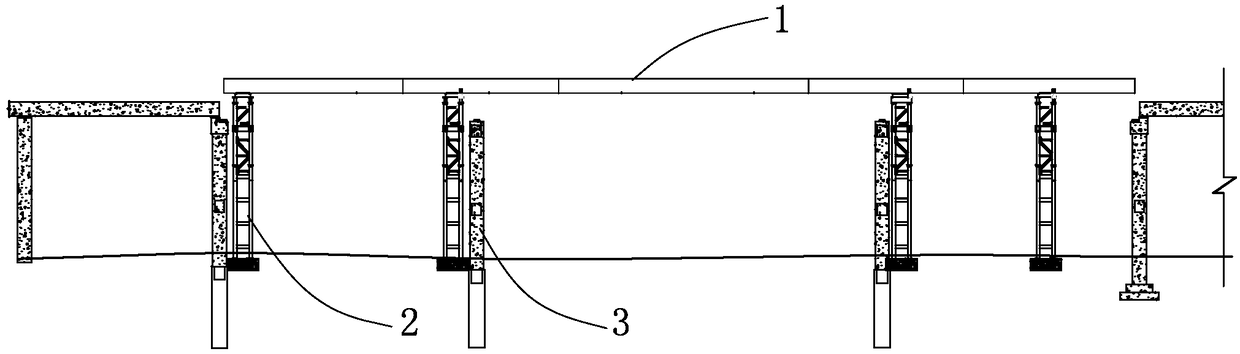

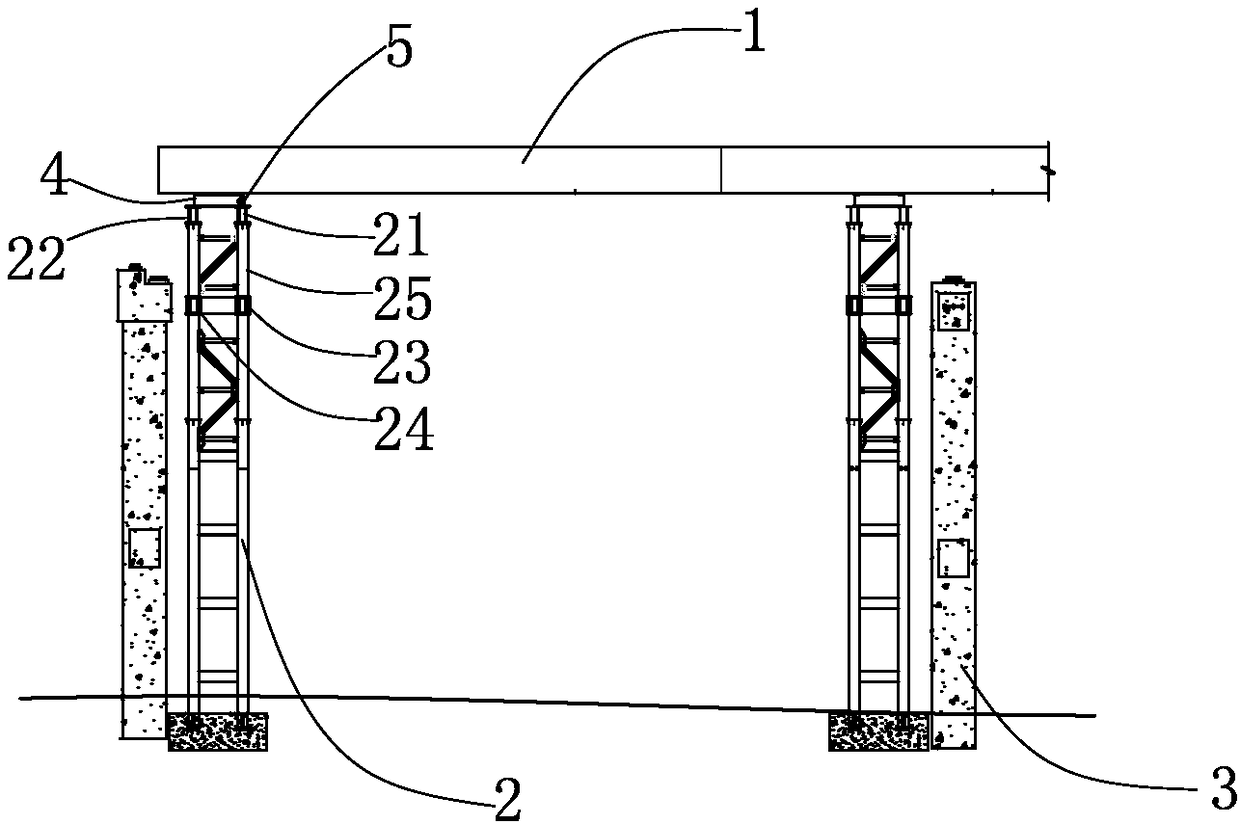

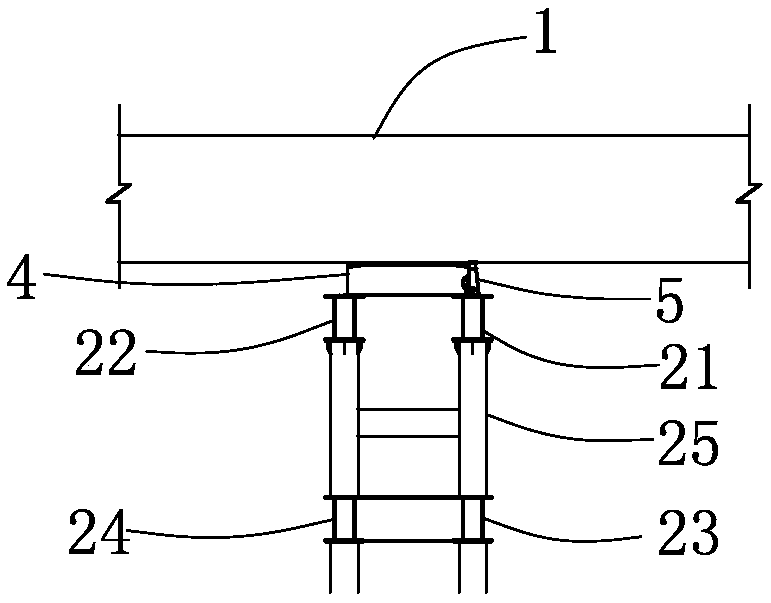

[0026] Such as figure 1 As shown, after the steel box girder 1 is pushed into place by the jacking method construction, it will be dropped to the permanent pier 3. Now the steel box girder is supported by the push bracket 2 during the push construction. Such as figure 2 , image 3 , Figure 4 As shown, two layers are arranged on the upper part of the push bracket 2, and each layer has two beams arranged in the direction of the bridge, wherein the upper beam includes the first upper beam 21 and the second upper beam 22, and the lower beam correspondingly includes the first lower beam 23 and The second lower beam 24 . The upper beam is equipped with jacking equipment, including slideway 4, traction jack, and correction device, etc., the bottom surface of the upper beam is flush with the top surface of the adjacent span prefabricated box girder, the lower beam is 1m lower than the support elevation, and the first lower beam 23 and the first upper beam 21, and between the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com