Water-based drilling fluid for shale gas wells and production method thereof

A technology for shale gas wells and production methods, which is applied in the field of water-based drilling fluid for shale gas wells and the production field of water-based drilling fluid for shale gas wells. It is impossible to take into account problems at the same time, to achieve the effect of improving the effect of sticking and suspending barite, improving quality and plugging ability, and solving high density and rheology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

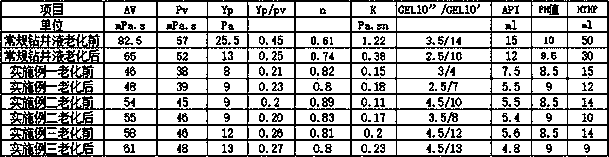

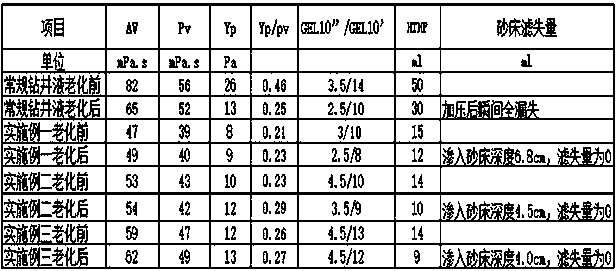

Embodiment 1

[0024] The production method of water-based drilling fluid for shale gas wells of the present invention comprises the following steps sequentially, (1) preparing raw materials according to the following components and weight content, water: 1000 parts; sodium-based bentonite: 45 parts; water-soluble inhibitor weighting agent type II: 500 parts; water-soluble inhibitor weighting agent type III: 100 parts; anti-slump agent non-fluorescent white asphalt: 15 parts; solid polymer alcohol: 10 parts; fluid loss control agent: 10 parts; polyamine inhibitor: 0.5 parts; Fine calcium carbonate: 20 parts; Extreme pressure lubricant: 10 parts; Coating inhibitor: 0.5 part; (2) After mixing sodium bentonite with water, keep stirring for 30 minutes under the stirring condition of 1000rpm, then increase the stirring speed to Continue to stir at 6000rpm for 30 minutes, and then place it at room temperature for curing for 24 hours; (3) at a stirring speed of 6000rpm, add water-soluble inhibitory ...

Embodiment 2

[0026] The production method of water-based drilling fluid for shale gas wells of the present invention comprises the following steps in turn, (1) prepare raw materials according to the following components and weight content, water: 1000 parts; sodium-based bentonite: 48 parts; water-soluble inhibitor weighting agent type II: 500 parts; water-soluble inhibitor weighting agent type III: 100 parts; anti-slump agent non-fluorescent white asphalt: 18 parts; solid polymer alcohol: 15 parts; fluid loss additive: 15 parts; polyamine inhibitor: 0.8 parts; Fine calcium carbonate: 25 parts; Extreme pressure lubricant: 18 parts; Coating inhibitor: 0.7 part; (2) After mixing sodium bentonite with water, keep stirring for 40 minutes under the stirring condition of 2000rpm, then increase the stirring speed to Continue to stir at 8000rpm for 35 minutes, and then place it at room temperature for 28 hours of curing; (3) at a stirring speed of 8000rpm, add water-soluble inhibitory weighting age...

Embodiment 3

[0028] The production method of water-based drilling fluid for shale gas wells of the present invention comprises the following steps in turn, (1) prepare raw materials according to the following components and weight content, water: 1000 parts; sodium-based bentonite: 50 parts; water-soluble inhibitor weighting agent type II: 500 parts; Water-soluble inhibitor weighting agent type III: 100 parts; Inhibitor anti-slump agent non-fluorescent white asphalt: 20 parts; Solid polymer alcohol: 20 parts; Fluid loss control agent: 20 parts; Polyamine inhibitor: 1 part; Fine calcium carbonate: 30 parts; Extreme pressure lubricant: 25 parts; Coating inhibitor: 1 part; (2) After mixing sodium-based bentonite with water, continue stirring for 60 minutes under the stirring condition of 4000rpm, then increase the stirring speed to Continue to stir at 10000rpm for 40 minutes, and then place it at room temperature for 30 hours of curing; (3) at a stirring speed of 10000rpm, add water-soluble in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com