Ultra-flat cavern middle rock pillar supporting structure and construction method

A support structure and construction method technology, applied in the direction of earth drilling, mining equipment, installation of bolts, etc., can solve the problems that cannot meet the requirements of large-span and large-section space use, and achieve large-scale mechanized operations, high safety, Good implementability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

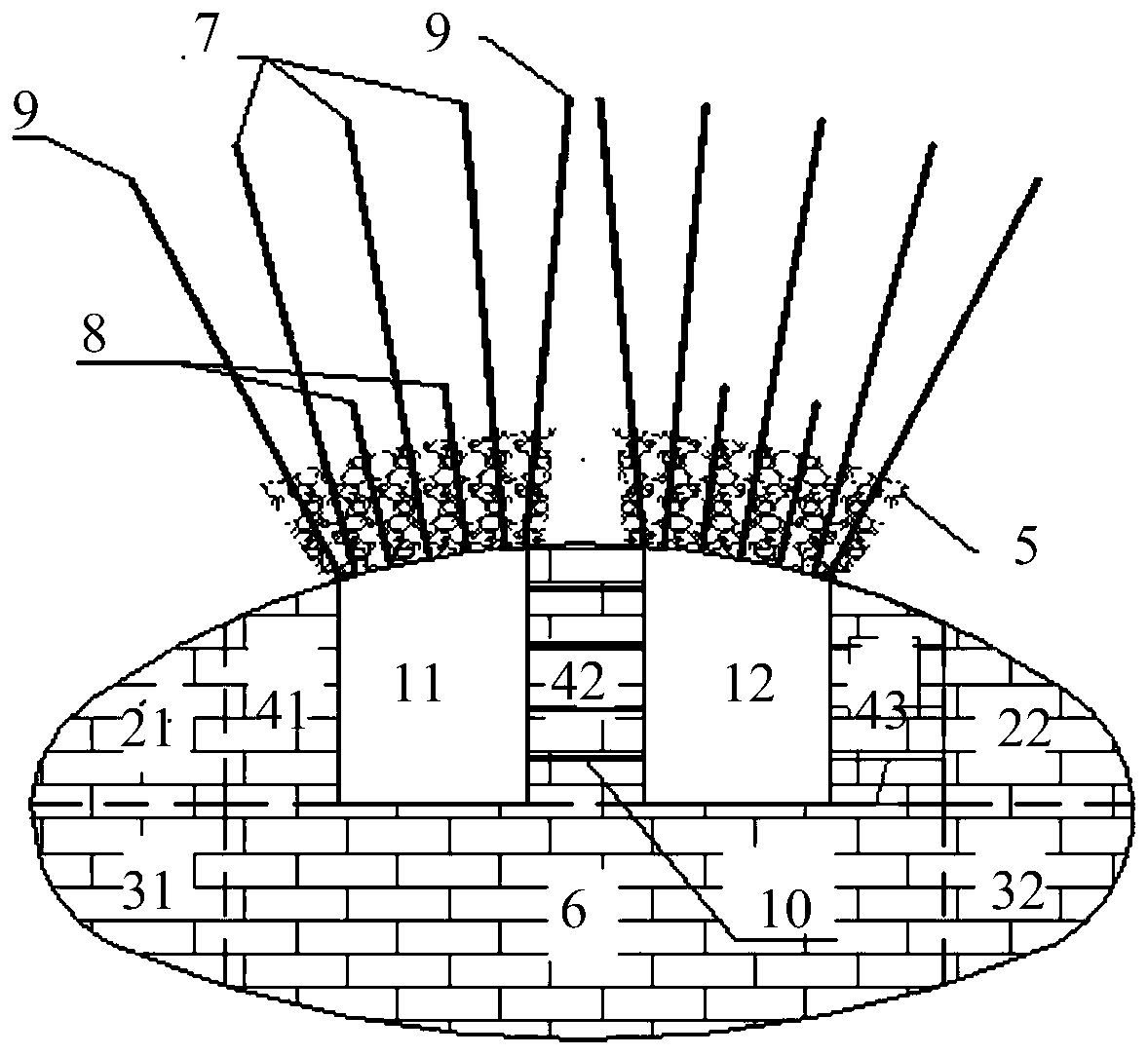

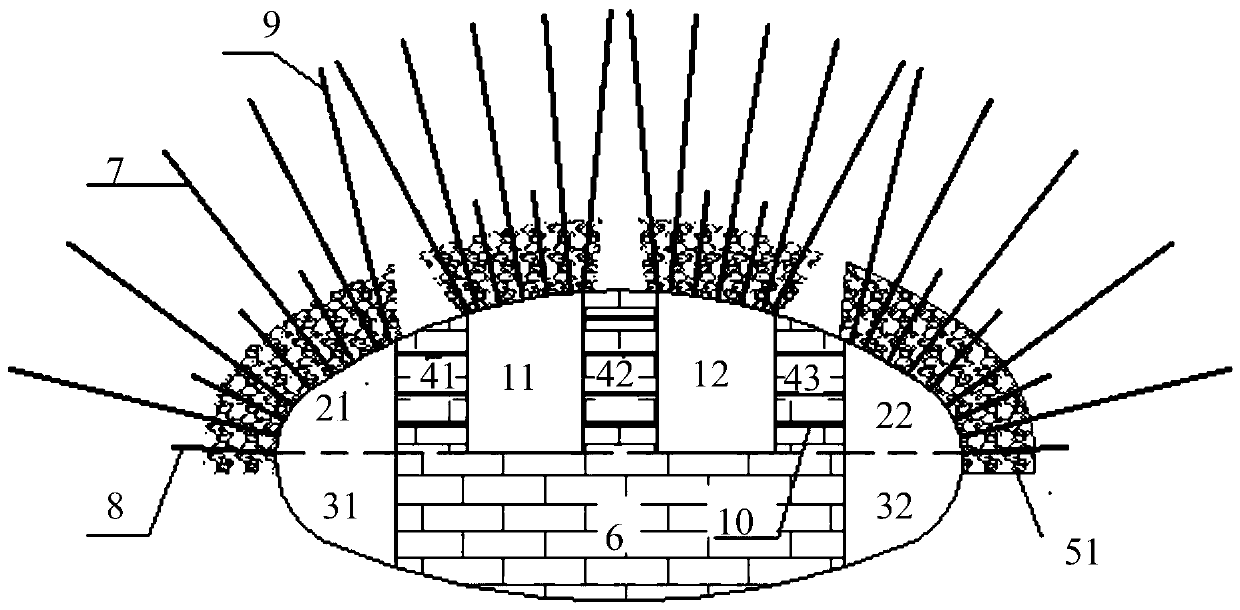

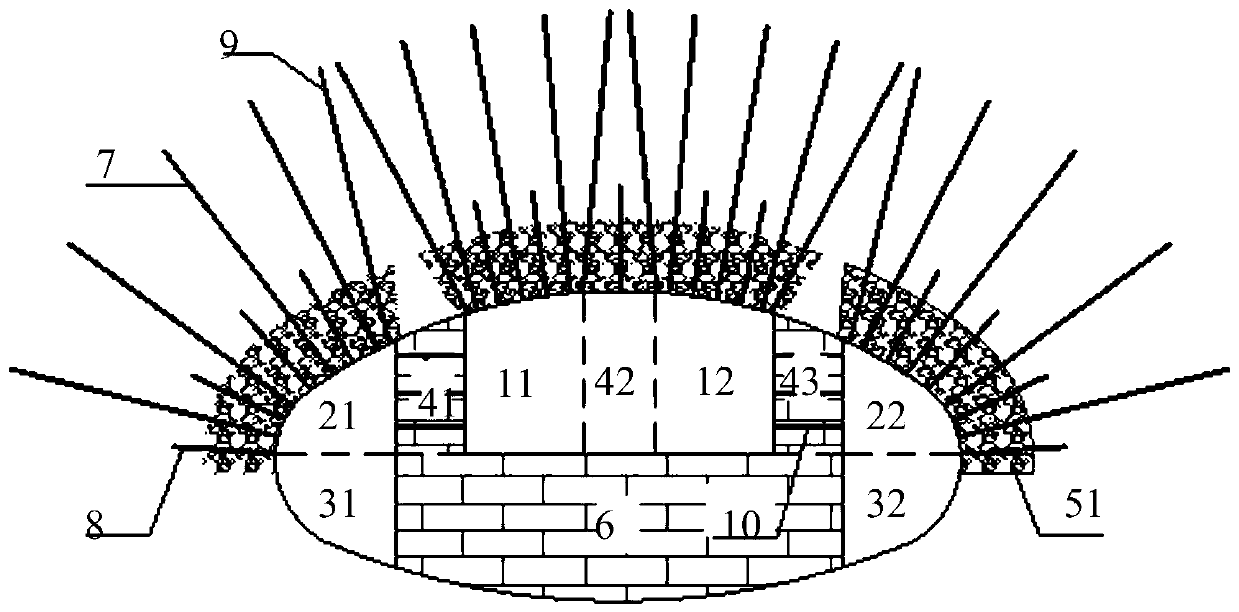

[0026] In order to better understand the purpose, structure and function of the present invention, a rock pillar support structure and construction method in an ultra-flat cavern of the present invention will be further described in detail in conjunction with the accompanying drawings.

[0027] Such as Figure 1 to Figure 6D As shown, it is shown as a rock column support structure and construction method in an ultra-flat cavern of the present invention. The support structure includes a radial system anchor cable support structure 7, a radial system bolt support structure 8, an anchor cable 9, anchor rod 10, and the radial system anchor cable support structure 7 is provided with a plurality of anchor cables 9, and the anchor cables 9 go from the excavated pilot tunnel (middle pilot tunnel 1) on both sides to the top of the reserved middle rock pillar 4 Inclined drilling; the radial system bolt support structure 8 is provided with a plurality of bolts, and the bolts are arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com